Sample preparation is important

In X-ray fluorescence (XRF) analysis, sample preparation is an important step because it can significantly impact both the quality and the efficiency of the analysis.

Proper sample preparation is essential for obtaining accurate and reliable results in XRF analysis. By preparing the sample in a way that minimizes any potential sources of error and ensures that the sample is representative of the material being analyzed, you can increase the confidence in the results of the analysis.

The choice of sample preparation method for X-ray fluorescence (XRF) analysis can depend on a variety of factors, including the element or elements being analyzed, the sample matrix, and the desired level of accuracy and precision.

Table of Contents

For some elements, such as iron, a simple powder form may be sufficient for XRF analysis. However, for other elements, such as calcium or sodium, using a different sample preparation method may be necessary to obtain accurate and reliable results.

One common sample preparation method for XRF analysis is pressing the sample into a pellet form. This method is often used when analyzing elements that are present at low concentrations in the sample, as the pellet form can help to concentrate the element and improve the sensitivity of the analysis.

Another sample preparation method that is often used in XRF analysis is fusing the sample into a bead form. This method is often used when analyzing elements that are present in a sample with a complex matrix, as the bead form can help to eliminate interferences and improve the accuracy of the analysis.

Main effects

In X-ray fluorescence (XRF) analysis, there are several factors that can affect the accuracy and reliability of the results, and proper sample preparation can help to minimize these factors.

One such factor is the mineralogical effect, which can occur when the analyzed element is present in different crystal phases or forms. This can cause the XRF signal to vary, leading to inaccurate results. To minimize the mineralogical effect, it is often necessary to use a sample preparation method that helps to bring the minerals in the sample to the same oxidation state. One such method is fusing the sample into a bead form, which can help to eliminate the influence of different crystal phases on the XRF signal.

Another factor that can affect XRF measurements is the particle size effect, which occurs when the distance between particles in the sample is not uniform. This can cause the X-ray beam to follow different paths before reaching the detector, leading to inaccurate results. To minimize the particle size effect, it is often necessary to use a sample preparation method that helps to bring the particles in the sample more uniformly together. One such method is pressing the sample into a pellet form, which can help to reduce the influence of particle size on the XRF signal.

it is often beneficial to reduce the particle size of the sample as much as possible before pressing it into a pellet form. This can help to minimize the particle size effect, which can occur when the distance between particles in the sample is not uniform. By reducing the particle size, you can reduce the influence of particle size on the XRF signal and improve the accuracy and reliability of the results.

There are several methods that can be used to reduce the particle size of a sample, including crushing, grinding, and milling. These methods use mechanical force to break the sample down into smaller particles. The specific method used will depend on the nature of the sample and the desired particle size.

It is generally considered acceptable to have a particle diameter of 40 micrometers (µm) or lower when preparing a sample for XRF analysis. However, the optimal particle size will depend on the element being analyzed and the desired level of accuracy and precision.

Overall, reducing the particle size of the sample before pressing it into a pellet is an important step in XRF sample preparation. By minimizing the particle size effect, you can improve the accuracy and reliability of the results and maximize the efficiency of the analysis.

The ways to prepare samples for XRF analysis

There are several common methods for preparing samples for X-ray fluorescence (XRF) analysis, and the choice of method will depend on the specific requirements of the analysis and the desired level of accuracy and precision.

One of the simplest sample preparation methods is to use the sample in a powdered form, with no additional preparation. This method is often used when analyzing elements that are present at relatively high concentrations in the sample, and when the sample is already in a form that is suitable for XRF analysis.

Another common sample preparation method is pressing the sample into a pellet form. This method is often used when analyzing elements that are present at low concentrations in the sample, as the pellet form can help to concentrate the element and improve the sensitivity of the analysis. It is also often used when the sample is in a form that is not suitable for XRF analysis, such as a liquid or a solid with a complex matrix.

A third common sample preparation method is fusing the sample into a bead form. This method is often used when analyzing elements that are present in a sample with a complex matrix, as the bead form can help to eliminate interferences and improve the accuracy of the analysis. It is also often used when the sample is in a form that is not suitable for XRF analysis, such as a solid with a heterogeneous structure.

Before using any of these methods, it may be necessary to perform additional sample preparation steps to reduce the particle size of the sample, depending on the nature of the sample and the desired level of accuracy and precision. This can involve crushing, grinding, or milling the sample to reduce the particle size to an acceptable level for XRF analysis.

Advantages of using pressed pellets for XRF analysis

One advantage of using pressed pellets for XRF analysis is that it can deliver better results compared to using the sample in a powdered form with no additional preparation. This is because the pellet form can help to concentrate the element being analyzed and minimize the influence of factors such as the particle size effect and the mineralogical effect, which can occur when the analyzed element is present in different crystal phases.

Another advantage of using pressed pellets is that it is a relatively fast and convenient sample preparation method. It can be performed using automated systems or manual presses, and it is generally considered to be a cost-effective and reliable technique that has become an industry standard.

Overall, pressing the sample into a pellet form is a flexible and efficient sample preparation method that can deliver excellent results for XRF analysis. While fusing the sample into a bead form can also eliminate the mineralogical effect and the particle size effect, it is typically a more complex and expensive method, and it may not be necessary for all types of XRF analysis.

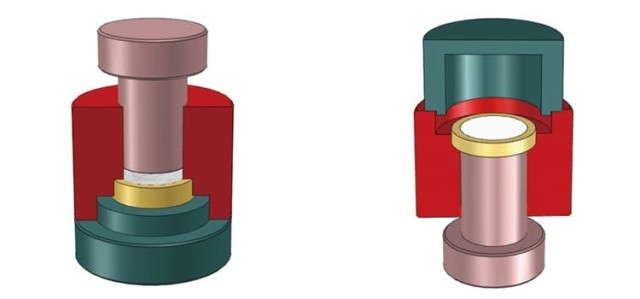

Pellet dies

Pellet dies are an important component of the sample preparation process when using pressed pellets for X-ray fluorescence (XRF) analysis.

Pellet dies function as the mold in which the sample is pressed to form the pellet. They are typically made of a hard, durable material such as stainless steel or tungsten carbide, and they must be able to withstand the high loads that are applied during the pressing process.

In addition to being able to withstand high loads, pellet dies must also have the right size to fit into the sample holder of the XRF instrument. The sample holder is the part of the instrument where the pellet is placed for analysis, and it is important that the pellet fits securely and accurately in the holder to ensure that the results of the analysis are reliable.

Pellet dies can also be designed to speed up the sample preparation process and make it easier and safer for the user. For example, some pellet dies are designed to allow the sample to be easily loaded into the die, and others are designed to minimize the risk of injury to the user during the pressing process.

Overall, pellet dies are an essential component of the sample preparation process when using pressed pellets for XRF analysis. They help to form the pellet, ensure that it fits securely in the sample holder, and may also help to improve the efficiency and safety of the sample preparation process.

How to choose XRF Pellet Press

There are several factors to consider when choosing an X-ray fluorescence (XRF) pellet press for sample preparation. Some of the key considerations include:

- Compatibility with the sample: It is important to select a pellet press that is compatible with the sample material and can produce pellets of the desired size and shape.

- Pressure range: The pressure range of the pellet press should be sufficient to produce pellets of the desired density and strength.

- Size and shape of the molds: The size and shape of the molds should be suitable for the sample holder of the XRF instrument and should produce pellets of the desired size and shape.

- Ease of use: The pellet press should be easy to operate and should have features such as automatic pressurization, automatic pressure holding, and automatic demolding to make the sample preparation process more efficient and consistent.

- Safety features: It is important to select a pellet press that has safety features such as pressure relief valves to minimize the risk of injury to the user.

- Cost: The cost of the pellet press should be considered, as well as any ongoing maintenance or consumable costs.

Overall, it is important to carefully consider these factors when selecting an XRF pellet press to ensure that you choose a tool that is suitable for your specific needs and applications.

Kintek XRF Pellet Press

The Kintek xrf pellet press is a popular sample preparation tool for X-ray fluorescence (XRF) analysis and infrared spectroscopy. It is designed to be fast and easy to use, and it is capable of producing both solid and highly permeable pellets, making it a versatile option for a variety of applications.

The pellet press is equipped with a set of fluorescent molds and is designed to automatically convert the pressure program of the mold. This helps to make the sample preparation process more efficient and consistent, and it can also help to improve the safety of the process.

Some of the features of the Kintek xrf pellet press that contribute to its versatility and ease of use include automatic pressurization/slow pressurization, automatic pressure holding, timing pressure relief, and automatic demolding. These features allow the pellet press to produce high-quality pellets with minimal user intervention, making it a convenient and reliable sample preparation tool.

Overall, the Kintek xrf pellet press is a well-regarded sample preparation tool that can be a valuable addition to any laboratory performing XRF or infrared spectroscopy analysis. Its ability to produce both solid and highly permeable pellets, as well as its user-friendly design, make it a versatile and reliable option for a wide range of applications.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- XRD Sample Holder X-ray Diffractometer Powder Slide

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

Related Articles

- Operating of Automatic Lab xrf Pellet Press

- Understanding Cold Isostatic Pressing: Process, Comparisons, and Applications

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages

- What is xrf analysis and how to making pressed xrf pellets

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method