Table of Contents

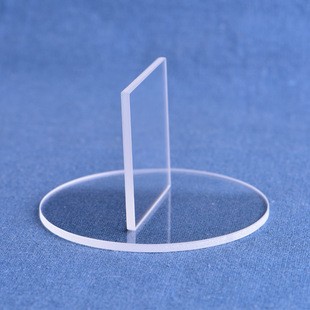

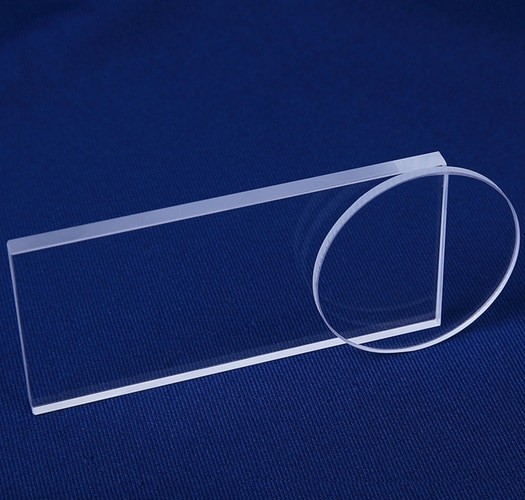

Introduction to Optical Quartz Plates

Optical quartz plates stand out as exceptional materials in the world of optics. Their unique composition and properties make them indispensable for a wide range of applications, from ultraviolet transmission to precision optics and beyond. This comprehensive guide delves into the fascinating world of optical quartz plates, exploring their advantages, specifications, and the factors that set them apart from glass.

Applications of Optical Quartz Plates

Optical quartz plates are versatile components with a wide range of applications, particularly in industries requiring precision and high performance. Their unique properties, such as superior ultraviolet transmission, low thermal expansion, and excellent electrical insulation, make them ideal for various optical, industrial, and scientific applications.

Ultraviolet Transmission and Clear Lens Optics:

Fused quartz exhibits exceptional ultraviolet transmission, making it an ideal material for lenses and other optical devices used in the ultraviolet spectrum. Its high clarity and low absorption ensure accurate and reliable transmission of ultraviolet light.

Precision Mirror Substrates:

Quartz plates possess a very low coefficient of thermal expansion, which minimizes dimensional changes due to temperature fluctuations. This property makes them suitable for use as precision mirror substrates, ensuring stable and accurate optical performance.

Thermocouple Protection Tubes:

Fused quartz is commonly used to manufacture thermocouple protection tubes, which are essential for protecting thermocouples from harsh environments. Its high temperature resistance and chemical inertness make it an ideal material for this application.

Industrial and Scientific Applications:

Beyond its optical applications, quartz plates are also widely used in various industrial and scientific fields. Their high purity, excellent electrical insulation qualities, and resistance to extreme temperatures make them suitable for applications such as:

- Sight glasses and level gauges

- X-ray tubes and vacuum tubes

- Chemical vapor deposition (CVD) and diffusion procedures

- End caps and transfer carriers

- Thermocouple tubes and boats

The diverse range of applications for optical quartz plates underscores their versatility and value in various industries, including optical manufacturing, electronics, aerospace, and scientific research. Their unique properties enable them to meet the demanding requirements of these industries, providing reliable and high-performance solutions.

Key Specifications of Optical Quartz Plates

Optical quartz plates, also known as fused quartz or synthetic silica, possess exceptional properties that make them indispensable for various scientific, industrial, and optical applications. Their unique characteristics include:

1. Very Low Coefficient of Thermal Expansion:

Optical quartz plates exhibit an extremely low coefficient of thermal expansion (CTE), typically around 0.55 x 10^-6 /°C. This property ensures minimal dimensional changes with temperature variations, enabling them to withstand rapid temperature fluctuations without cracking or warping.

2. High-Temperature Resistance:

Quartz plates possess exceptional thermal resistance, withstanding temperatures up to 1500°C. This attribute makes them ideal for applications involving high-temperature processes, such as semiconductor fabrication, glassblowing, and chemical reactions.

3. Optical Clarity:

Optical quartz plates are characterized by their high optical clarity, allowing for exceptional light transmission. They exhibit minimal absorption and scattering of light, making them suitable for various optical applications, including lenses, prisms, and windows.

4. High Chemical Purity:

Quartz plates are composed of ultra-pure silica (SiO2), resulting in high chemical purity. They are resistant to most acids, bases, and organic solvents, making them ideal for applications in harsh chemical environments.

5. Excellent Electrical Insulation Qualities:

Optical quartz plates are excellent electrical insulators, possessing high resistivity and low dielectric loss. This property makes them suitable for electrical applications, such as insulators, capacitors, and high-voltage components.

Distinguishing Quartz from Glass

Differences in Chemical Composition and Structure

Quartz and glass are both composed of silicon dioxide (SiO2), but the key difference lies in their chemical composition and molecular structure. Quartz is a crystalline mineral with a highly ordered, symmetrical structure, while glass is an amorphous solid with a random, disordered molecular arrangement. This difference in structure is due to the different formation processes of the two materials. Quartz forms naturally through the crystallization of molten rock, while glass is produced by rapidly cooling molten silica.

Impact on Molecular Form and Symmetry

The difference in molecular structure between quartz and glass has a significant impact on their physical properties. Quartz crystals have a regular, repeating pattern of atoms, which gives them a high degree of symmetry and strength. Glass, on the other hand, has a more disordered structure, which results in lower symmetry and strength.

Implications for Optical Properties and Applications

The difference in molecular structure between quartz and glass also affects their optical properties. Quartz is birefringent, meaning that it splits light into two polarized rays. This property makes quartz useful for optical applications such as polarizers, lenses, and prisms. Glass, on the other hand, is isotropic, meaning that it transmits light equally in all directions. This property makes glass useful for applications such as windows, bottles, and containers.

Applications of Quartz in Various Industries

Quartz is a versatile material with a wide range of applications across various industries, owing to its unique properties, including shock resistance, high-temperature tolerance, and optical clarity.

Optical Applications:

- Eyeglasses: Quartz is used in the production of high-quality eyeglasses due to its excellent optical properties, providing clear and distortion-free vision.

- Self-Cleaning Windows: Quartz-coated windows repel dirt and water, reducing the need for cleaning and maintenance. They are commonly used in skylights, skyscrapers, and other high-rise buildings.

Photovoltaic Applications:

- Solar Energy: Quartz is a crucial component in solar cells, converting sunlight into electricity. Its high transparency and low thermal expansion coefficient make it an ideal material for solar panels.

Device Applications:

- Computer Chips: Quartz is used as a substrate for semiconductor wafers, providing a stable and durable base for electronic circuits.

- Displays: Quartz is employed in liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs), ensuring high image quality and durability.

- Communications: Quartz is used in optical fibers for high-speed data transmission due to its low optical loss and wide bandwidth.

Functional and Decorative Finishes:

- Protective Films: Quartz-based coatings provide scratch resistance and durability to various surfaces, such as glass, metal, and plastics.

- Plating: Quartz is used in electroplating processes to create decorative and protective finishes on metals, enhancing their appearance and resistance to corrosion.

Additional Applications:

- Laboratory Equipment: Quartz test tubes, beakers, and other laboratory glassware are commonly used in scientific research and analysis due to their chemical inertness and high thermal stability.

- Semiconductors: Quartz is employed in the manufacturing of semiconductors, providing a precise and controlled environment for the fabrication of electronic devices.

- Sight Gages: Quartz is used in sight gages to monitor liquid levels in tanks and pipelines, ensuring accurate and reliable measurements.

- Optics: Quartz is utilized in optical components, such as lenses, prisms, and mirrors, due to its high optical clarity and low refractive index.

- Pharmaceutical and Industrial Processes: Quartz is used in pharmaceutical and industrial processes, including UV disinfection, chemical etching, and high-temperature applications.

Conclusion

Optical quartz plates stand out as exceptional materials for specialized optical applications due to their unique properties, including extremely low thermal expansion, high-temperature resistance, optical clarity, and electrical insulation qualities. Their versatility extends across industries, from ultraviolet transmission to precision optics, scientific research, and even consumer products. As technology continues to evolve, the demand for optical quartz plates is expected to grow, paving the way for further advancements and innovative applications.

Related Products

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- High Temperature Resistant Optical Quartz Glass Sheet

- CVD Diamond Optical Windows for Lab Applications

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Infrared High Resistance Single Crystal Silicon Lens

Related Articles

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

- Understanding Quartz Electrolytic Cells: Applications, Mechanisms, and Advantages

- Unlocking the Power of Optical Quartz Plates: Applications and Benefits

- Unveiling the Exceptional Properties and Applications of Optical Quartz Plates

- Infrared Heating Quantitative Flat Plate Mold: Design, Applications, and Benefits