PTFE material

Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

Item Number : PTFE-12

Price varies based on specs and customizations

- Material

- PTFE

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

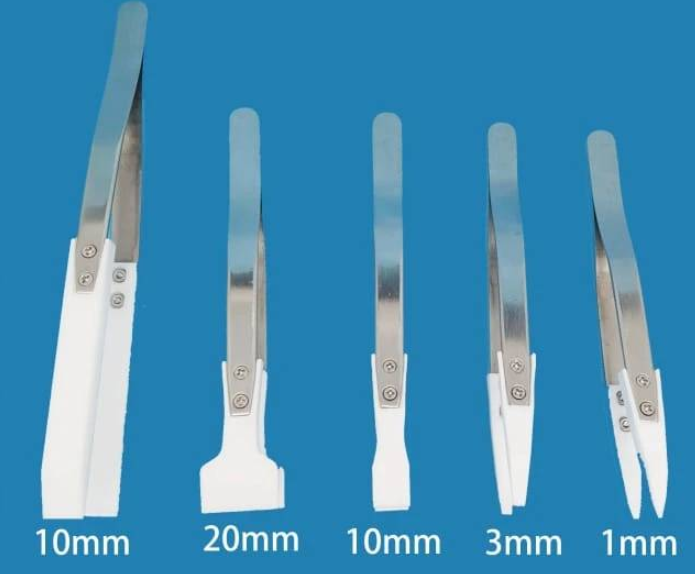

Polytetrafluoroethylene (PTFE) tweezers: high and low temperature resistance (operating temperature -200°C~+250°C), corrosion resistance, non-stick surface, used to hold solar silicon wafers, etc. There are two kinds of fixed support and fixed support without fixed support. Various specifications of PTFE tweezers can be customized according to your needs. It is used to clamp raw materials, metal particles, solar silicon wafers, lithium wafers, etc. under harsh conditions. There are column type, no column type, flat type and pointed type.

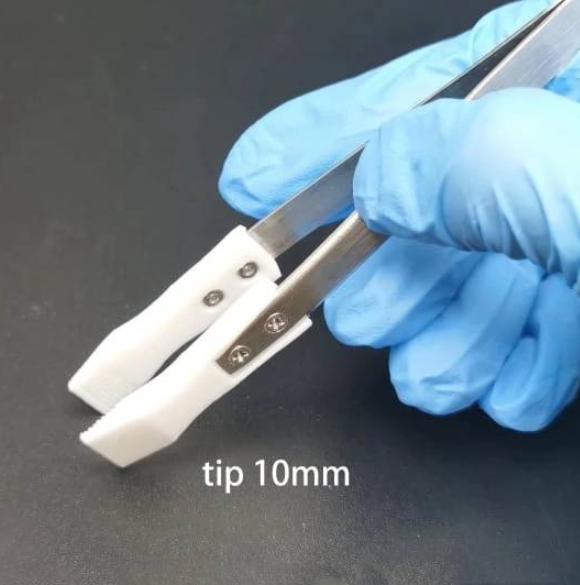

Fixed pillar: It can prevent the fork of the tweezers from being misaligned due to excessive force when picking up the object, making the object clamping unstable.

Without fixed support: a wide range of applications.

Tips: It is used to hold relatively small samples, such as solar silicon wafers, lithium wafers, etc.

Flat head: used to clamp flake and thin samples, which can prevent the clamped sample from slipping due to the small contact area during clamping; the head can be made into a tooth shape, which is more convenient and practical when grabbing special samples.

Detail & Parts

Specifications

| Category | Model / Description | Specification |

|---|---|---|

| Standard White PTFE | Tweezers with Fine Tip | 1mm |

| Tweezers with Fine Tip | 3mm | |

| Tweezers with Fine Tip | 8mm | |

| Tweezers with Fine Tip | 10mm | |

| Tweezers with Fine Tip (Extended) | 10mm | |

| Tweezers with Fine Tip | 13mm | |

| Tweezers with Fine Tip | 20mm | |

| Tweezers with Fine Tip | 28mm | |

| Anti-static PTFE | Tweezers with Wide Tip | 1mm |

| Tweezers with Wide Tip | 3mm | |

| Tweezers with Wide Tip | 10mm | |

| Tweezers with Wide Tip | 20mm |

Advantages

- Smooth surface, high mechanical strength, good toughness.

- Anti-static and ESD safe material.

- High temperature resistant; heat stable for continuous use from -40°C to 150°C (-40°F to 302°F).

- High wear resistance; high purity, suitable for clean room environment.

- Resistant to chemical corrosion of HF, nitric acid, hydrochloric acid and other acids.

- Resistant to UV and X-ray radiation.

- Resistant to strong acid, strong alkali and organic solvent corrosion.

- Low pollution, very little metal element content.

- Excellent insulation resistance, not affected by temperature and frequency changes.

- Non-toxic and physiologically inert.

Trusted by Industry Leaders

4.9 / 5

PTFE tweezers are the best choice for delicate tasks; they are durable, precise, and don't scratch surfaces.

4.7 / 5

The tweezers have a soft touch surface that prevents damage to sensitive materials and are perfect for handling electronics and small objects.

4.8 / 5

PTFE tweezers are great for handling samples in the lab without scratching or breaking them. I highly recommend them for anyone working with delicate materials.

4.6 / 5

I use these tweezers in my cleanroom and they work perfectly. They are lightweight and strong, and the non-magnetic material is a big plus.

4.9 / 5

The tweezers are strong and durable, and the tips are precise enough for even the most delicate tasks. I'm very happy with my purchase.

4.7 / 5

These tweezers are a must-have for anyone working with small, delicate objects. They are very well-made and the tips are perfectly aligned.

4.8 / 5

I've been using these tweezers for a few months now and they are still as good as new. They are very sturdy and the tips haven't lost their sharpness.

4.6 / 5

The tweezers are very lightweight and easy to handle. They are also very precise, which makes them perfect for working with small objects.

4.9 / 5

These tweezers are the perfect tool for handling delicate materials. They are made of high-quality materials and are very well-made. I highly recommend them.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

PTFE measuring cylinder are a rugged alternative to traditional glass cylinders. They are chemically inert over a wide temperature range (up to 260º C), have excellent corrosion resistance and maintain a low coefficient of friction, ensuring ease of use and cleaning.

Custom PTFE Teflon Parts Manufacturer for PTFE Containers

PTFE container is a container with excellent corrosion resistance and chemical inertness.

Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

PTFE crucibles, made from pure Teflon, offer chemical inertness and resistance from -196°C to 280°C, ensuring compatibility with a wide range of temperatures and chemicals. These crucibles feature machine-finished surfaces for easy cleaning and prevention of contamination, making them ideal for precise laboratory applications.

Custom PTFE Teflon Parts Manufacturer for Gaskets and More

Gaskets are materials placed between two flat surfaces to enhance the seal. To prevent fluid leakage, sealing elements are arranged between static sealing surfaces.

Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

Seats and inserts are vital components in the valve industry. As a key component, polytetrafluoroethylene is usually selected as the raw material.

Custom PTFE Teflon Parts Manufacturer Grinding Bowl

PTFE is renowned for its exceptional chemical resistance, thermal stability, and low friction properties, making it a versatile material in various industries. The PTFE grinding bowl, specifically, finds applications where these properties are crucial.

Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

The PTFE beaker is a laboratory container that is resistant to acid, alkali, high and low temperatures and is suitable for temperatures ranging from -200ºC to +250ºC. This beaker has excellent chemical stability and is widely used for heat treatment samples and volume analysis.

Custom PTFE Teflon Parts Manufacturer F4 Conical Flask Triangular Flask 50 100 250ml

The PTFE triangular flask, also known as a Teflon reagent bottle, is a robust, chemical-resistant alternative to traditional glass bottles, suitable for handling both acids and alkalis. These bottles are unbreakable, lightweight, and feature a leak-proof screw cap, making them ideal for laboratory use.

Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

The PTFE funnel is a piece of laboratory equipment used primarily for filtration processes, particularly in the separation of solid and liquid phases in a mixture. This setup allows for efficient and rapid filtration, making it indispensable in various chemical and biological applications.

Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

PTFE flask, is a versatile laboratory container made from PTFE, offering exceptional chemical resistance, temperature stability, and non-stick properties. Ideal for handling corrosive substances and high-temperature applications, these flasks are essential in various laboratory procedures, including heating, mixing, and storage of chemicals.

Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

PTFE cleaning racks are mainly made of tetrafluoroethylene. PTFE, known as the "King of Plastics", is a polymer compound made of tetrafluoroethylene.

Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

This product is used for stirrer recovery, and is resistant to high temperature, corrosion, and strong alkali, and is almost insoluble in all solvents. The product has a stainless steel rod inside and a polytetrafluoroethylene sleeve outside.

Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

The PTFE magnetic stirring bar, made from high-quality PTFE, offers exceptional resistance to acids, alkalis, and organic solvents, coupled with high-temperature stability and low friction. Ideal for laboratory use, these stirring bars are compatible with standard flask ports, ensuring stability and safety during operations.

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

The precision-made PTFE test tube racks are completely inert and, due to the high temperature properties of PTFE, these test tube racks can be sterilized (autoclaved) without any problems.

Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

PTFE mesh sieve is a specialized test sieve designed for particle analysis in various industries, featuring a non-metallic mesh woven from PTFE filament. This synthetic mesh is ideal for applications where metal contamination is a concern . PTFE sieves are crucial for maintaining the integrity of samples in sensitive environments, ensuring accurate and reliable results in particle size distribution analysis.

Custom PTFE Teflon Parts Manufacturer for Air Valve Applications

PTFE small air valve for gas-liquid sampling and sampling bag for sample collection.

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

PTFE centrifugal tubes are highly valued for their exceptional chemical resistance, thermal stability, and non-stick properties, making them indispensable in various high-demand sectors. These tubes are particularly useful in environments where exposure to corrosive substances, high temperatures, or stringent cleanliness requirements are prevalent.

Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

PTFE cleaning racks are mainly made of tetrafluoroethylene. PTFE, known as the "King of Plastics", is a polymer compound made of tetrafluoroethylene.

Custom PTFE Teflon Parts Manufacturer for F4 PTFE Volumetric Bottle

The PTFE Volumetric Flask, a robust alternative to glass and PP flasks, excels in measuring both acidic and alkaline liquids. Characterized by its chemical inertness, translucency, and wide volume options, this flask ensures a non-leachable, ultra-clean background. Its non-stick surface simplifies cleaning and maintenance, making it ideal for harsh laboratory conditions.

Related Articles

Versatile Applications of PTFE Cleaning Racks: Enhancing Laboratory Efficiency and Precision

Delve into the diverse applications of PTFE cleaning racks in laboratory settings. Discover how these essential tools optimize cleaning processes, enhance precision, and contribute to overall laboratory efficiency and accuracy.

PTFE Shovel: A Comprehensive Guide to Its Uses, Advantages, and Applications

Discover the versatile applications of PTFE shovels in various industries, including their unique properties, benefits, and real-world examples. Explore the advantages of PTFE shovels over traditional materials and delve into the specific uses in laboratory settings.

PTFE Cleaning Racks: The Ultimate Guide to Cleaning and Drying Labware

In this comprehensive guide, we'll delve into the world of PTFE cleaning racks, exploring their benefits, applications, and the best practices for cleaning and drying labware to ensure optimal performance and longevity.

Revolutionize Your Spectroscopy Analysis with FTIR Pellet Press

FTIR (Fourier Transform Infrared) spectroscopy is a widely used technique to analyze the chemical composition of various materials. This method is particularly useful for samples that are difficult to analyze using other techniques.

How to choose laboratory gloves

There are several factors to consider when choosing disposable gloves for use in a laboratory setting. These include the material of the gloves, the thickness and durability of the gloves, and the level of protection they provide against chemicals and other hazards.

Exploring the Advanced Capabilities of Spark Plasma Sintering (SPS) Furnaces

Dive into the world of Spark Plasma Sintering (SPS) furnaces, their innovative technology, and applications in material science. Learn how SPS furnaces revolutionize the sintering process with high-speed, efficiency, and precision.

Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

Explore the advanced features and applications of Spark Plasma Sintering Furnaces (SPS) in material science. Learn how SPS technology offers rapid, efficient, and versatile sintering for various materials.

The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

From high-purity gas delivery pipelines to precision electrical insulation components, the multi-faceted application of PTFE in the semiconductor industry chain provides important guarantees for the purity, stability and reliability of the manufacturing process.

Innovative Application of PTFE in Mechanical Seals

PTFE has become one of the core materials in the field of mechanical seals due to its unique chemical stability, low friction coefficient (0.04-0.15), wide temperature range (-268°C to +315°C) and excellent corrosion resistance (pH 0-14).

PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

The unique advantages of polytetrafluoroethylene (PTFE) in high temperature and corrosion resistance analyze why it has become an indispensable material in industry, especially in applications in harsh environments.

Performance and application of polytetrafluoroethylene (PTFE) in high temperature environment