Working Principle

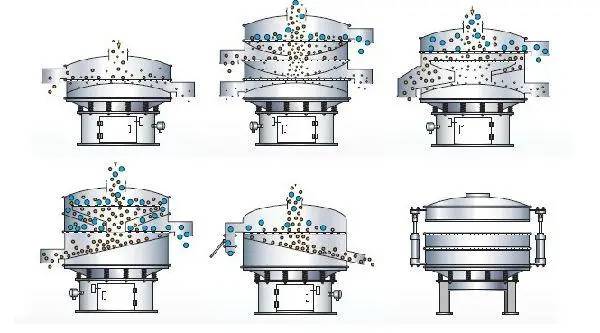

The working principle of three-dimensional vibrating screeners involves the generation of vibration force and the implementation of a three-dimensional throwing motion. These screeners utilize an adjustable eccentric block structure for fine-tuning the vibration frequency and amplitude, ensuring optimal performance for different materials and experimental requirements. Additionally, some advanced models feature intelligent control systems, enabling remote monitoring and control through computers or mobile devices, thereby enhancing experimental efficiency and reliability.

Vibration Force Generation

To generate the vibration force necessary for the screening process, three-dimensional vibrating screeners are equipped with motors that are typically installed on both sides of the equipment. These motors transmit the vibration force to the screen through exciters, resulting in the screen's vibration.

Three-Dimensional Throwing Motion

In some three-dimensional vibrating screeners, electromagnetic drive devices are used to produce a three-dimensional throwing motion. This motion ensures that materials move uniformly across the entire analysis screen surface, enhancing the accuracy and effectiveness of particle separation.

Screening Process

During the screening process, the material being analyzed is subjected to the vibration force exerted on the screen. The particles respond to this force and exhibit various movement trajectories based on their particle size, shape, density, and other characteristics. As a result, particles larger than the sieve holes remain on the sieve surface, forming oversize particles. On the other hand, particles smaller than the sieve holes pass through the sieve, forming undersize items.

Adjustment Function

Three-dimensional vibrating screeners are equipped with an adjustable eccentric block structure. The position or number of eccentric blocks can be altered, allowing the adjustment of the vibration amplitude and frequency of the screen surface. This versatility enables the screen to accommodate different materials and meet specific experimental needs.

Intelligent Control

Some advanced three-dimensional vibrating screeners are equipped with intelligent control systems. These systems offer the convenience of remote control and monitoring through computers or mobile devices. Researchers and operators can remotely adjust various parameters, such as vibration intensity, shaking frequency, and screen aperture, to optimize the experimental process. This intelligent control capability improves experimental efficiency and reliability, enabling better research outcomes.

The working principle of three-dimensional vibrating screeners forms the foundation of their widespread application in various industries. These screeners offer numerous advantages, such as accuracy, ease of operation, and intelligent control, which contribute to improved screening efficiency and experimental accuracy.

Features and Advantages

The dry three-dimensional vibrating screener offers several key features and advantages that make it a preferred choice for screening applications. Its high screening accuracy, low noise, and high efficiency set it apart from other screening equipment. Let's explore its features and advantages in detail.

Efficient Screening Process

The dry three-dimensional vibrating screener utilizes a multi-layer screen structure that allows for continuous grading and screening of particles. This unique design enables the equipment to separate granular materials based on different particle sizes. Larger particles are trapped above the upper screen, while smaller particles pass through the sieve holes and reach the lower screen, ensuring precise separation.

Additionally, the equipment employs high-frequency and small-amplitude vibrations to efficiently complete the screening process in a short period. This working method improves overall screening efficiency, resulting in energy savings and reduced production costs.

Stable Screening Accuracy

One of the notable advantages of the dry three-dimensional vibrating screener is its ability to maintain stable screening accuracy. The screen features a fully sealed structure, minimizing the risk of blockages. Moreover, the equipment is equipped with an automatic screen cleaning device that prevents dust from flying, ensuring a clean screening surface.

Furthermore, the screen incorporates an automatic compensation function, extending its service life and enhancing screening accuracy. These features guarantee reliable and accurate screening results, making the dry three-dimensional vibrating screener an indispensable tool in laboratories and industrial production settings.

Versatile Applications

Thanks to its efficient working principle, the dry three-dimensional vibrating screener finds extensive use in various industries. It is suitable for both dry sieving and wet sieving applications, making it adaptable to different screening requirements. The equipment is widely employed in soil analysis, pharmaceutical, metallurgy, mining, coal, grain, and other industries.

In these industries, the dry three-dimensional vibrating screener proves effective in analyzing particles. It can accurately screen a wide range of inorganic and organic substances, including sand, rock, clay, granite, feldspar, coal, soil, powders, grains, seeds, and more. The versatility of this equipment makes it a valuable asset in diverse fields of study and production.

Unique Structural Features

The dry three-dimensional vibrating screener incorporates several unique structural features that enhance its screening and filtering capabilities. The multi-layer screen structure plays a crucial role in classifying and screening materials of different particle sizes, ensuring accuracy and precision in the screening process.

Moreover, the equipment offers an adjustable amplitude function, enabling users to select the appropriate amplitude based on their specific needs. This adjustability allows for efficient screening of solid particles with varying sizes and properties, improving overall screening efficiency and productivity.

Quiet and Reliable Operation

Noise levels are often a concern in screening equipment. However, the dry three-dimensional vibrating screener operates with low noise levels, providing a comfortable working environment. Its reliable performance, high screening accuracy, and repeatable screening results make it a reliable tool for various screening applications.

In conclusion, the dry three-dimensional vibrating screener stands out for its efficient screening speed, repeatable screening results, and energy-saving capabilities. Its features and advantages make it a preferred choice for screening applications in laboratories and industrial settings. Whether for particle analysis or material classification, this equipment ensures high screening accuracy, low noise, and improved efficiency.

Applications

The dry three-dimensional vibrating screener is a versatile screening and filtration equipment that finds extensive use in various industries. Its unique design and efficiency make it an indispensable tool in many fields. Let's explore some of the industries where this equipment is widely used.

Pharmaceutical Industry

In the pharmaceutical industry, the dry three-dimensional vibrating screener plays a crucial role in particle analysis and screening during the production process. It enables the particle size analysis of pharmaceutical raw materials, ensuring the quality and stability of pharmaceuticals. Additionally, it can be used for the separation and classification of different components in pharmaceuticals, meeting the specific requirements of pharmaceutical processes. This equipment greatly improves production efficiency and safeguards the quality of pharmaceutical products.

Chemical Industry

The chemical industry requires accurate particle size analysis and particle separation of chemical raw materials to ensure the desired product quality and performance. The dry three-dimensional vibrating screener excels in quickly and precisely screening a wide range of chemical raw materials. By doing so, it enhances production efficiency and ensures superior product quality. This equipment is also capable of grading different particle sizes in chemical products, catering to diverse application needs.

Food Industry

In the food industry, product uniformity and consistency are essential factors. The dry three-dimensional vibrating screener is employed for food particle size analysis and particle separation. By effectively screening food particles, this equipment ensures the uniformity and consistency of food products. It contributes to maintaining the desired quality and texture of various food items, guaranteeing customer satisfaction.

Building Materials Industry

In the building materials industry, the dry three-dimensional vibrating screener is used for particle analysis and screening of materials such as sand, cement, and concrete. This equipment aids in improving the quality and performance of building materials. By accurately screening and separating particles, it ensures that the materials meet the required standards. It also enables the identification and removal of impurities, resulting in superior final products.

Mining Industry

The mining industry extensively relies on the dry three-dimensional vibrating screener for efficient ore and mineral powder screening and classification. By employing this equipment, the taste of ores can be improved, subsequently enhancing the efficiency of the mineral processing operations. It enables the accurate separation and classification of various ores and mineral powders, contributing to maximizing the yield and quality of mined materials.

The dry three-dimensional vibrating screener stands out as an advanced screening equipment, widely applicable across various industries. Its working principle and structural characteristics make it an ideal choice for numerous applications. This equipment works by generating a three-dimensional throwing motion effect through electromagnetic drive, allowing efficient and precise screening and separation of solid particles. Notable features include a multi-layer screen structure, adjustable amplitude, large screening capacity, fully sealed structure, convenient screen cleaning, and a compact design.

The versatility of the dry three-dimensional vibrating screener is evident in its ability to perform both dry and wet sieving operations. It excels in screening various inorganic and organic substances, including sand, rock, clay, granite, feldspar, coal, soil, powders, grains, and seeds. Its working principle ensures high efficiency, precise screening, and repeatable screening results, establishing it as an indispensable screening equipment in laboratories and industrial production.

Understanding the working principle and applications of the dry three-dimensional vibrating screener provides insights into its value and advantages in the screening field. Its exceptional performance in terms of efficiency and accuracy makes it an essential equipment widely used across industries. Whether in the pharmaceutical, chemical, food, building materials, or mining industry, this equipment proves invaluable in enhancing product quality, streamlining processes, and maximizing overall productivity.

Conclusion

The dry three-dimensional vibrating screener is a crucial screening equipment used in laboratories and industrial production. Its working principle involves the generation of vibration forces and a three-dimensional throwing motion, resulting in accurate and efficient screening of granular materials. The screener also offers adjustment functions and intelligent control, allowing for precise screening processes. The features and advantages of this equipment include high screening accuracy, low noise, repeatable screening results, and energy-saving capabilities. Additionally, the dry three-dimensional vibrating screener finds applications in various industries such as soil analysis, pharmaceuticals, metallurgy, mining, coal, and grain. Overall, this equipment is instrumental in achieving reliable screening results in different settings.

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

Related Articles

- The Ultimate Guide to the Application and Benefits of Vibratory Sieve Shaker in Laboratory Testing

- Unlocking the Power of Sieving Machines: Functions, Applications and Maintenance

- The Role of Powder Characteristics in Cold Isostatic Pressing

- FTIR Pellet Press The Game-Changer in Spectroscopy Analysis

- Revolutionizing Lab Efficiency: The Ultimate Guide to Laboratory Sieving Machines