Table of Contents

Introduction to Handheld Alloy Analyzers

Handheld alloy analyzers, the latest marvel in material analysis technology, offer a dynamic solution for professionals in various industries. These portable devices utilize the precision of XRF spectrometry to perform on-site, non-destructive metal analysis. This article will delve into the remarkable features, diverse applications, and significant advantages of these analyzers. Join us as we explore how handheld alloy analyzers are revolutionizing quality control and material verification in a multitude of industries.

Key Applications of Handheld Alloy Analyzers

Handheld alloy analyzers are indispensable tools in various industries due to their versatility and efficiency. These devices are capable of analyzing not only solid metals but also liquids and powders, making them suitable for a wide range of applications. The non-destructive nature of these analyzers ensures that the integrity of the samples remains intact, which is crucial for subsequent use or further analysis.

Scrap Metal Sorting: One of the primary uses of handheld alloy analyzers is in the sorting of scrap metals. This process is vital for recycling facilities where different types of metals need to be identified and sorted accurately to ensure proper recycling and to maintain the quality of the recycled materials. The speed and accuracy of these analyzers allow for rapid identification and sorting, optimizing the recycling process and reducing labor costs.

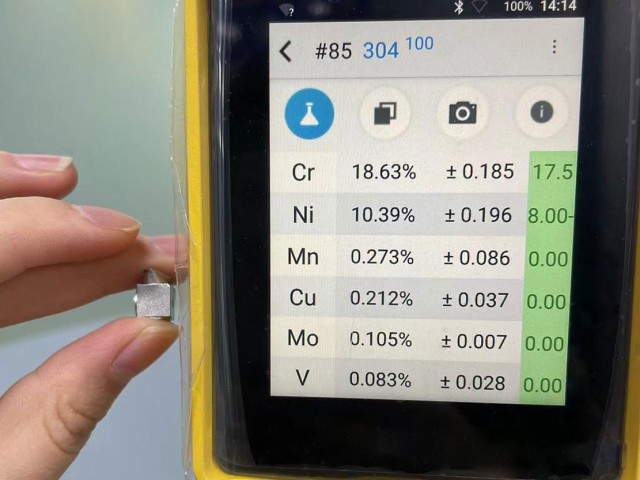

Factory Material Inspection: In manufacturing settings, handheld alloy analyzers play a critical role in incoming material inspection. They help ensure that the materials used in production meet the required specifications by quickly identifying the alloy grades and chemical compositions. This proactive approach helps prevent the use of substandard materials, thereby maintaining product quality and safety standards.

Production Quality Control: Quality control is another significant application of these analyzers. They are used to verify the composition of materials during the production process, ensuring that each batch of products adheres to the set standards. This real-time monitoring helps in identifying and rectifying any deviations early, preventing the production of defective items and reducing waste.

Rapid Alloy Grade Identification: Handheld alloy analyzers are also employed for rapid alloy grade identification, which is particularly useful in industries where materials are used in critical applications such as aerospace, automotive, and nuclear power. The ability to quickly and accurately identify the grade of an alloy helps in ensuring that the right materials are used, thereby enhancing safety and performance.

Non-Destructive Testing: The non-destructive nature of handheld alloy analyzers makes them ideal for various inspection tasks where the integrity of the sample is crucial. Unlike traditional methods that might damage the sample, these analyzers provide detailed chemical composition information without altering the sample. This feature is particularly beneficial in industries where materials are expensive or irreplaceable.

In summary, handheld alloy analyzers offer a versatile, efficient, and non-destructive solution for a variety of applications across different industries. Their ability to analyze solids, liquids, and powders, coupled with their rapid and accurate results, makes them an essential tool for quality control, material inspection, and alloy grade identification.

Advanced Features of Handheld Alloy Analyzers

Handheld alloy analyzers have revolutionized the field of metal analysis by offering rapid, accurate, and non-destructive testing capabilities. These devices are equipped with advanced features that enhance their performance and usability, making them indispensable tools for various industries including scrap metal recycling, quality control in manufacturing, and precious metal analysis.

Fast Results and Nondestructive Analysis One of the key features of handheld alloy analyzers is their ability to provide results within seconds. This rapid analysis is achieved through the integration of powerful fundamental parameters (FP) and empirical coefficient methods. Upon triggering the device, the alloy grade can be identified in as little as 1-2 seconds, with extended testing time providing laboratory-level analysis results. Unlike destructive testing methods, handheld XRF analyzers ensure that samples remain undamaged, which is crucial for preserving the integrity of valuable materials.

Accurate and Reliable Results The accuracy of handheld alloy analyzers is enhanced by high-performance X-ray systems that incorporate either Si-Pin detectors or high-resolution, high-sensitivity SDD detectors. These advanced detectors, combined with sophisticated algorithms, deliver precise elemental analysis results that users can trust. With a comprehensive library of over 1600 alloy grades, these devices offer superior accuracy in grade identification, ensuring that the analysis meets stringent quality control standards.

User-Friendly Interface and Operation Handheld alloy analyzers are designed with user convenience in mind. They feature ergonomic designs that are lightweight and easy to handle, even for extended periods. The devices are equipped with a tapered test head that can easily detect curved or corner parts, such as welds, making them versatile for various applications. Additionally, large-capacity batteries ensure that the analyzers can operate for up to 10-12 hours, making them ideal for on-site testing without the need for frequent recharging.

Minimal Training and Maintenance The simplicity of operation is another significant advantage of these analyzers. With a point-and-shoot design, users require minimal training to operate the device effectively. The icon-style user interface is intuitive and straightforward, further reducing the learning curve. Maintenance costs are also kept low, thanks to rugged designs that meet IP54 standards for dustproof and waterproof protection, ensuring reliable performance even in challenging environmental conditions.

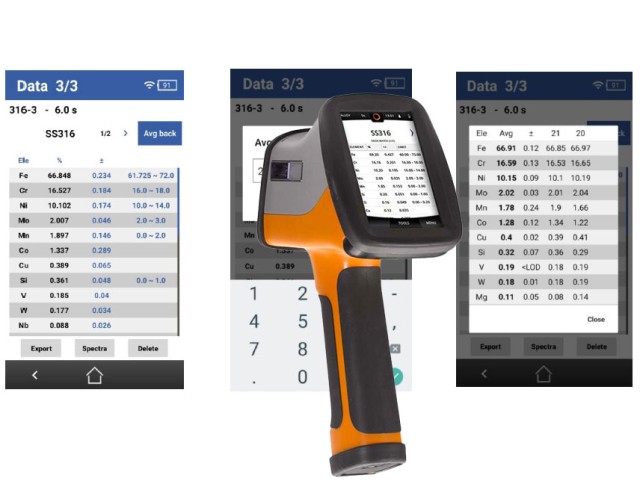

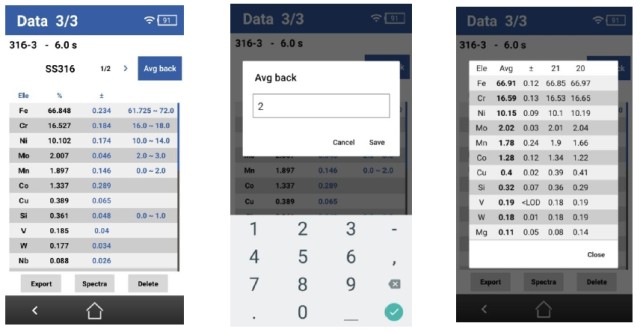

Advanced Software and Display Features Handheld alloy analyzers come with a 5-inch color touch screen that features a backlight function, making it easy to view results even in direct sunlight. The touch screen is also operable while wearing gloves, enhancing its usability in various work environments. The software includes a comprehensive grade library that covers over 1600 alloys, and users have the flexibility to modify existing grades, add new ones, or customize the library to suit specific needs. Additionally, the analyzers can store up to 100,000 test results, including spectrograms and sample images, providing a valuable database for future reference and analysis.

In conclusion, the advanced features of handheld alloy analyzers make them essential tools for industries that require quick, accurate, and non-destructive metal analysis. Their user-friendly design, coupled with high-performance analytical capabilities, ensures that they remain at the forefront of quality control and material analysis in various sectors.

Operational Benefits and Ease of Use

The compact design of these devices ensures they do not take up much space on the table or counter, making them ideal for various environments including jewelry stores and industrial settings. The ergonomic design, complete with LED lighting, enhances ease of operation, ensuring that even in low-light conditions, the devices can be operated with precision.

One of the standout features is the precise determination of the presence and amount of trace alloying elements and harmful heavy metals such as cadmium, lead, and indium. This capability is crucial not only for determining the value of materials but also for ensuring compliance with environmental and health regulations. The built-in dual CCD cameras facilitate precise positioning of samples, enhancing the accuracy of the analysis.

For more detailed analysis, an optional small spot collimator (3mm, 10mm) is available, which is particularly useful for detecting smaller samples. Additionally, the option to integrate external devices such as a portable printer, external balance, and display further extends the functionality and adaptability of the equipment.

The battery-operated nature of these devices makes them truly portable, allowing for use in a variety of settings without the need for a constant power source. This portability is complemented by a remarkably fast and user-friendly operation. Simply closing the lid and pressing a button initiates the analysis, with results displayed within seconds on a vibrant touch-screen color monitor. This eliminates the need for handling harsh chemicals or acids, thereby enhancing safety and reducing potential damage to attire and surfaces.

Accuracy and precision are maintained through the use of a high-performance SDD detector, which can identify a variety of alloy grades and display element content in real time. This fast analysis capability supports 7x24 operation, crucial for high-volume production environments. The equipment's design also facilitates easy integration and installation on robotic arms or production lines, enhancing its utility in automated inspection solutions.

The rugged design, meeting IP54 standards for dustproof and waterproof capabilities, ensures continuous and normal operation in temperatures ranging from -10°C to 50°C. This robustness addresses the environmental challenges often encountered on factory sites, reducing downtime and maintenance costs.

User-friendly software with an intuitive design further simplifies operation, requiring minimal training. Data can be easily exported for various purposes, enhancing the versatility of the information gathered. The low cost of maintenance, coupled with the quick recovery of costs through automated inspection solutions, makes these devices not only operationally efficient but also economically viable.

In summary, these devices offer significant advantages including fast analysis, minimal training requirements, and low maintenance costs. Their ergonomic design and compact size enhance operational efficiency and reduce labor costs, making them a valuable asset in a wide range of applications.

Data Management and Reporting

Handheld alloy analyzers are equipped with advanced data management systems, allowing for the storage of up to 100,000 test results, including spectrograms and sample images. These systems are designed to facilitate easy data transmission to PCs, supporting remote real-time monitoring. This capability ensures comprehensive data control and analysis, enhancing the efficiency and effectiveness of operations in various industries, including metal processing, scrap metal recycling, and quality control in manufacturing.

The integration of Ethernet (RJ-45 network port) in these analyzers enables seamless connectivity with PCs, allowing for the immediate transfer of data and the implementation of remote monitoring systems. This feature is particularly beneficial in environments where continuous data analysis is crucial, such as in 24/7 operating factories or during critical mining operations.

Moreover, the analyzers are equipped with intelligent software that enhances their functionality. This software not only simplifies the user interface but also allows for customization of data fields and user profiles, ensuring that the workflow solutions are tailored to meet specific business needs. The inclusion of WiFi capability further enhances the analyzers' functionality by enabling the seamless transfer and remote viewing of sample readings, which is crucial for timely decision-making in dynamic environments.

The analyzers' data management capabilities are complemented by their robust design and analytical features. They are capable of fast, nondestructive analysis, providing results in seconds. This speed is critical in applications such as metal scrap sorting, factory incoming material inspection, and production quality control. The analyzers can identify alloy grades within 1-2 seconds and provide laboratory-level analysis results with minimal sample preparation, making them ideal for rapid identification and sorting of materials.

In terms of elemental analysis, these handheld devices cover a wide range from potassium to uranium, with analyzable content ranging from 1ppm to 99.99%. This broad analytical scope ensures that they are suitable for a variety of applications, including quality management of alloys, coatings, liquids, and other materials.

The rugged design of these analyzers, which includes features such as dust-proof, moisture-proof, and vibration-proof capabilities, ensures that they can operate effectively in various environmental conditions, including those found in factory sites. This durability is essential for maintaining uninterrupted operation and reducing maintenance costs, thereby contributing to the quick recovery of the cost of the online automatic detection equipment.

Overall, the advanced data management and reporting features of handheld alloy analyzers significantly enhance their utility in a wide range of applications, from mineral exploration to quality control in manufacturing. The ability to manage and analyze data effectively in real-time, coupled with the analyzers' robust design and analytical capabilities, makes them indispensable tools for modern industries.

Environmental and Safety Considerations

The XRF 200 precious metal analyzers are engineered with a strong emphasis on environmental safety and operator protection. These devices utilize non-destructive testing methods, which eliminate the need for hazardous chemicals commonly associated with traditional assay techniques like fire assay. This not only protects the environment by reducing chemical waste but also ensures a safer working environment for operators.

Safety features of the XRF 200 include a closed-beam design that prevents any x-ray exposure to customers or operators, ensuring compliance with health and safety regulations. Additionally, the analyzer is equipped with rear view lead glass and LED lighting, enhancing visibility and safety during operation. This setup allows for clear observation of the analytical process without compromising the integrity of the sample or the health of the operator.

The non-destructive nature of the XRF 200 is particularly beneficial in preserving the value and integrity of precious metal samples. Unlike destructive methods such as acid and fire assay, which can alter or destroy the sample, the XRF 200 leaves the tested materials intact. This is crucial for industries where the resale or further processing of tested materials is a consideration.

Moreover, the XRF 200 is designed to be user-friendly, requiring minimal training for operators. The intuitive software not only simplifies the operation but also provides alerts when element concentrations exceed set limits, aiding in the immediate identification of potential contamination issues. This proactive approach helps maintain high standards of quality control, particularly in industries where precision and safety are paramount, such as metal production, processing, and manufacturing.

The compact and ergonomic design of the XRF 200 further enhances its practicality in various settings, including retail environments and industrial sites. Its rugged construction, compliant with IP54 standards for dustproof and waterproof protection, ensures reliable operation even in challenging environmental conditions. The analyzer can function effectively in temperatures ranging from -10°C to 50°C, making it suitable for use in diverse geographical locations.

In summary, the XRF 200 precious metal analyzers are not only technologically advanced but also prioritize environmental sustainability and operator safety. Their non-destructive testing capabilities, combined with user-friendly features and robust design, make them an ideal choice for ensuring accurate and safe analysis of precious metals and other materials across various industries.

Future Trends and Innovations in Handheld Alloy Analysis

As technology advances, handheld alloy analyzers continue to evolve, incorporating more sophisticated algorithms and features. The integration of AI and machine learning is expected to enhance their accuracy and efficiency, making them even more indispensable in the field of material analysis and quality control.

Enhanced Accuracy through AI and Machine Learning

The future of handheld alloy analyzers lies in the integration of artificial intelligence (AI) and machine learning. These technologies can analyze vast amounts of data collected from various sources, improving the accuracy of alloy identification and composition analysis. Machine learning algorithms can be trained to recognize patterns and anomalies in the data, leading to more reliable and precise results. This not only enhances the quality control process but also reduces the likelihood of errors, which is crucial in industries where even minor discrepancies can have significant consequences.

Real-Time Data Analysis and Feedback

Advancements in data processing capabilities are enabling real-time analysis and feedback from handheld alloy analyzers. This means that as soon as a sample is tested, the analyzer can provide immediate results, allowing for instant decision-making on product quality and compliance. This real-time capability is particularly beneficial in high-volume production environments where rapid inspection and sorting are required.

Improved User Interfaces and Ease of Use

Handheld alloy analyzers are also expected to feature more intuitive and user-friendly interfaces. With advancements in touch-screen technology and software design, these devices will be easier to operate, even for those with minimal training. This accessibility is crucial for industries where a high turnover of staff or the need for quick deployment of equipment is common.

Enhanced Durability and Versatility

Future handheld alloy analyzers will likely be designed to withstand harsh environments and operate under various conditions. This durability is essential for field use, where devices may be exposed to extreme temperatures, moisture, or rough handling. Additionally, the versatility of these devices will be improved to analyze a wider range of materials, including not only metals but also liquids and powders, expanding their application in various industries.

Integration with IoT and Cloud Computing

The integration of handheld alloy analyzers with the Internet of Things (IoT) and cloud computing will further enhance their capabilities. Data collected from these devices can be stored and analyzed in the cloud, allowing for better data management and sharing across different departments or even different companies. This integration also enables predictive maintenance, where the devices can alert users to potential issues before they become critical, thus reducing downtime and maintenance costs.

Conclusion

The future of handheld alloy analyzers is promising, with advancements in technology poised to make them more accurate, efficient, and user-friendly. As these devices continue to evolve, they will play an increasingly vital role in ensuring the quality and integrity of materials across a wide range of industries. The integration of AI, machine learning, and other cutting-edge technologies will not only improve the performance of these analyzers but also expand their applications, making them an essential tool for modern material analysis and quality control.

Related Products

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- XRD Sample Holder X-ray Diffractometer Powder Slide

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

Related Articles

- Revolutionizing Quality Control: The Ultimate Guide to Handheld Lithium Battery Analyzers

- Understanding Saturated Calomel Reference Electrodes: Composition, Uses, and Considerations

- Comprehensive Guide to Reference Electrodes: Types, Applications, and Selection Criteria

- Comprehensive Guide to Rotating Disk Electrode (RDE) in Electrochemical Studies

- Advanced Techniques in Coating Evaluation Using Electrolytic Cells