Mechanism of Powder Molding

Migration and Heavy Accumulation

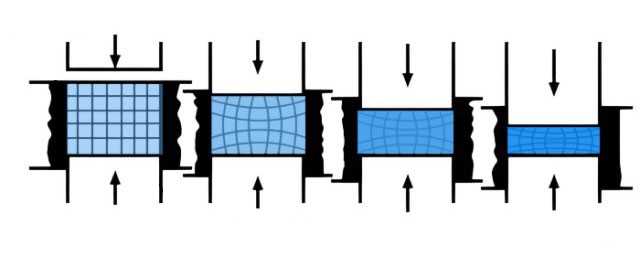

During the initial stages of cold isostatic pressing, a significant phenomenon known as migration and heavy accumulation occurs. This process is characterized by the large displacement of particles within the powder mixture. As the particles move, they undergo a dynamic rearrangement that is crucial for the subsequent densification of the material.

One of the key mechanisms in this stage is the arch bridge effect. This phenomenon describes how smaller particles within the mixture migrate and settle into the interstitial spaces or pores of larger particles. This filling process is not random but is governed by the principles of particle packing and density optimization. The smaller particles effectively bridge the gaps between larger particles, thereby reducing the overall porosity of the material.

The arch bridge effect is particularly important in achieving a uniform density distribution within the pressed product. By ensuring that smaller particles fill the voids left by larger ones, the material becomes more compact and less porous. This initial densification sets the stage for the subsequent stages of the pressing process, where further compaction and consolidation will take place.

In summary, the migration and heavy accumulation stage is fundamental to the overall success of cold isostatic pressing. It lays the groundwork for the structural integrity and density of the final product by optimizing particle distribution and reducing porosity through the arch bridge effect.

Local Flow and Fragmentation Stage

As the pressure continues to escalate during the cold isostatic pressing process, the initially loose powder particles undergo significant deformation. This stage is characterized by the fragmentation and rupture of particles under the intense pressure, particularly evident in brittle materials. For ductile metals, however, the response is markedly different; they exhibit plastic deformation.

In the case of ductile metals, the plastic deformation leads to an increase in the contact area between the angular peaks of the particles. This increase in contact area is not merely a surface phenomenon but a structural change that results in the formation of new contact points. These new contact points are crucial as they facilitate the subsequent stages of the process, where the particles begin to interlock and bond more effectively.

The following table summarizes the key differences in behavior between brittle and ductile materials during this stage:

| Material Type | Behavior Under Pressure | Resulting Effect |

|---|---|---|

| Brittle | Fragmentation and rupture | Loss of structural integrity |

| Ductile | Plastic deformation | Increase in contact area and formation of new contact points |

This stage is pivotal as it sets the foundation for the subsequent volume compression stage, where the densification of the material begins.

Volume Compression Stage

In the context of cold isostatic pressing, the Volume Compression Stage is a critical phase that distinguishes the behavior of different materials under pressure. Unlike ductile materials, brittle materials do not exhibit a volume compression stage. This is because brittle materials, such as ceramics or certain types of glass, lack the ability to deform plastically under pressure. Consequently, they do not undergo a process where their density increases significantly.

For ductile materials, such as metals, the situation is quite different. Under sufficient pressure, these materials can undergo plastic deformation, which allows for a more compact arrangement of particles. However, even in these cases, the density does not increase indefinitely. Instead, there is a point where further compression yields diminishing returns in terms of density improvement. This is due to the inherent limits of particle rearrangement and the constraints imposed by the material's structure.

| Material Type | Behavior Under Pressure | Density Change |

|---|---|---|

| Brittle | No volume compression | No increase |

| Ductile | Plastic deformation | Limited increase |

Understanding these distinctions is crucial for optimizing the cold isostatic pressing process. For brittle materials, the focus shifts to other stages of the process, such as the local flow and fragmentation stage, where the primary goal is to achieve a stable structure without significant density changes. In contrast, for ductile materials, the volume compression stage offers an opportunity to enhance density, albeit within certain limits.

Factors Affecting Cold Isostatic Pressing

Powder Properties

The properties of the powder used in cold isostatic pressing significantly influence the final product's characteristics. Atomized powder is known for its spherical shape, which contributes to a high density and uniform packing. This type of powder is particularly advantageous for achieving a consistent and high-quality end product.

On the other hand, electrolytic powder exhibits excellent formability, making it suitable for intricate shapes and designs. This flexibility in formability is crucial for applications where complex geometries are required.

In practice, a combination of large and small particles is often employed. This mixed particle size distribution helps in filling the voids between larger particles with smaller ones, thereby enhancing the overall density and reducing the porosity of the final product. This method leverages the arch bridge effect, where smaller particles fill the gaps created by larger ones, leading to a more compact and stable structure.

| Powder Type | Characteristics | Applications |

|---|---|---|

| Atomized Powder | Spherical, high density | Consistent, high-quality products |

| Electrolytic Powder | Good formability | Intricate shapes and designs |

| Mixed Particle Sizes | Reduces porosity, enhances density | General molding processes |

The choice of powder type and particle size distribution is not arbitrary but is carefully selected based on the specific requirements of the application, ensuring the best possible outcome in terms of density, formability, and final product quality.

Degassing Effect

In the context of cold isostatic pressing, the degassing effect plays a crucial role in ensuring the quality and integrity of the final product. This process involves the removal of trapped gases within the powder mixture, which can lead to defects such as cracks and elastic aftereffects if left unaddressed.

To achieve effective degassing, several techniques are employed. One common method is vacuum degassing, where the powder package is placed under a vacuum to extract any residual gases. This step is essential as it helps to minimize the formation of voids and imperfections in the final product.

Additionally, materials such as felt, filter paper, and graphite paper are strategically added to the package. These materials serve multiple purposes: they help in maintaining the integrity of the package, provide a barrier against contamination, and assist in the even distribution of pressure during the pressing process. The use of these materials is particularly important in ensuring that the powder particles are evenly compacted, thereby enhancing the overall density and strength of the molded product.

In summary, the degassing effect is a critical aspect of the cold isostatic pressing process, aimed at eliminating gas inclusions and ensuring the structural integrity of the final product. By employing techniques such as vacuum degassing and incorporating supplementary materials, manufacturers can significantly improve the quality and reliability of their products.

Additives and Lubricants

In the context of cold isostatic pressing (CIP), the judicious selection and application of additives and lubricants play a pivotal role in optimizing the molding process. Lubricants, such as glycerol, are specifically chosen to mitigate friction between particles, thereby reducing the adhesion between the die and the workpiece. This reduction in friction is crucial for several reasons:

-

Enhanced Particle Mobility: By minimizing the resistance between particles, lubricants facilitate smoother migration and repositioning of particles during the pressing process. This is particularly beneficial in the Migration and Heavy Accumulation stage, where large displacements between particles occur.

-

Improved Formability: The use of lubricants ensures that the particles can flow more freely, which is essential during the Local Flow and Fragmentation Stage. Here, the pressure causes deformation and fragmentation, and the presence of lubricants helps in maintaining the integrity of the material by preventing excessive wear and tear.

-

Uniform Pressure Distribution: Lubricants aid in the even distribution of pressure across the workpiece, which is critical for achieving consistent density and avoiding localized stress concentrations. This is especially important in the Volume Compression Stage, where the goal is to achieve a uniform and high-density final product.

In addition to lubricants, binders like glycerol are also employed to enhance the cohesiveness of the powder mixture. Binders ensure that the particles remain bonded together, even under the high pressures exerted during CIP. This bonding is essential for maintaining the structural integrity of the green body, which is the intermediate stage between powder compaction and final sintering.

The combination of lubricants and binders in the CIP process not only improves the mechanical properties of the final product but also extends the lifespan of the dies and molds used in the pressing operation. By reducing wear and tear on these components, the overall efficiency and cost-effectiveness of the CIP process are significantly enhanced.

Cold Isostatic Pressing Molding Process

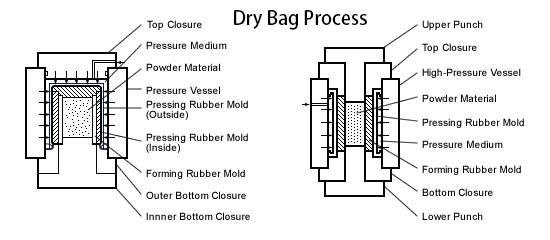

Dry Bag Method

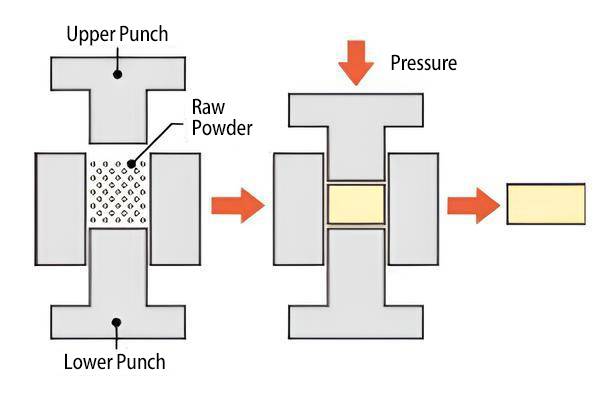

The Dry Bag Method is a critical step in the cold isostatic pressing process, involving several meticulous operations to ensure the integrity and precision of the final product. Initially, the powder is weighed to maintain consistency in composition and density. This step is followed by the filling of the powder into the designated package, ensuring an even distribution to prevent any air pockets or inconsistencies.

Once the powder is filled, the package is meticulously sealed to prevent any leakage during the subsequent vacuum degassing process. The sealed package is then placed into a high-pressure steel mold, which is essential for the application of uniform pressure across the entire surface of the powder.

The next phase involves increasing the pressure within the high-pressure cylinder. This step is crucial as it compresses the powder into a dense, solid form. The pressure is maintained for a specified duration to ensure complete consolidation and to achieve the desired density.

After the pressure has been maintained, it is gradually relieved, and the high-pressure cylinder is opened. The pressed blank, now in its consolidated form, is carefully removed from the mold. The final step involves measuring the size of the pressed blank to verify that it meets the required specifications. This measurement is a critical quality control measure to ensure that the final product adheres to the design criteria.

Measurement of the Size of the Pressed Green Sheet

The process of measuring the size of the pressed green sheet involves several meticulous steps, each critical to ensuring the final product's integrity and accuracy. The first step is the assembly and positioning of the mold. This involves precise alignment to ensure that the mold's dimensions are accurate and consistent. Following this, the mold surface is subjected to drying to remove any moisture that could affect the pressing process.

Next, the powder filling phase begins. This step requires a uniform distribution of the powder to achieve high-density filling. The uniformity ensures that the green sheet will have consistent mechanical properties throughout its structure. After the powder is evenly distributed, the mold is sealed to prevent any contamination or loss of material during the pressing process.

The final step before pressing is degassing. This involves removing any trapped air within the powder mixture to prevent defects such as voids or cracks in the final product. Degassing is typically achieved through vacuum methods, ensuring that the powder is as dense and homogeneous as possible before the application of pressure.

Each of these steps is crucial to the overall success of the cold isostatic pressing process, contributing to the creation of a high-quality, dimensionally accurate green sheet.

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Vacuum Cold Mounting Machine for Sample Preparation

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

Related Articles

- Understanding Cold Isostatic Pressing and Its Applications

- Application of Hot Isostatic Pressing Technology in Special Ceramic Preparation

- Cold Isostatic Pressing (CIP): A Proven Process for High-Performance Parts Manufacturing

- Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys

- Electric Lab Cold Isostatic Press (CIP): Applications, Benefits, and Customization