Introduction to Rotary Evaporation

Rotary evaporation is a technique used in laboratories to remove solvents from samples through the process of evaporation. It involves the use of a rotary evaporator, which consists of a rotating flask that is heated by a water or oil bath while being subjected to reduced pressure. The reduced pressure allows for the solvent to evaporate at a lower temperature, making it a gentle and effective method for solvent removal. Rotary evaporation has a wide range of applications in various industries, including pharmaceuticals, food and beverage, and chemical manufacturing. It has many advantages over other methods of solvent removal, including its ability to handle large volumes of samples and its efficiency in recovering solvents.

Table of Contents

- Introduction to Rotary Evaporation

- Advantages of Rotary Evaporators

- Rotary Evaporation in Molecular Cooking

- Applications of Rotary Evaporators in Industries

- How Rotary Evaporators Work

- Benefits of Using a Rotary Vacuum Evaporator

- Innovations in Rotary Evaporation Technology

- KINTEK Rotary Evaporation Advantage

- Conclusion: Mastering the Art of Rotary Evaporation

Advantages of Rotary Evaporators

Rotary evaporation is a crucial technique in the laboratory industry, and mastering the art of rotary evaporation is essential for high-quality results. In this paragraph, we will discuss the advantages of rotary evaporators over regular distillation equipment.

Lower Boiling Temperatures

One of the significant advantages of rotary evaporators is their ability to achieve separation of solvents and other compounds at lower temperatures than usual. The use of a vacuum system reduces the pressure of the system, allowing for the separation of compounds at lower temperatures. Lower water bath temperatures also ensure that the apparatus stays in good shape for a longer time as they are exposed to lower temperatures.

Faster Evaporation of Solvent

The process of separation in rotary evaporators involves two main forces: the centripetal force and friction. Centripetal force and friction act between the evaporation bottle or round-bottomed flask and the liquid mixture, allowing the mixture to form a film on the inner surface of the flask, creating a larger surface area for heating. The rotation of the flask at a constant speed also contributes to an increased surface area. Under the low pressure caused by the vacuum pump, the distillation speed is increased significantly due to the large surface area of the mixture.

Fewer Operations

A built-in lifting and falling motor in a rotary evaporator enables the automatic raising of the rotary bottle to a position just above the water bath for the rotation process. This means that a technician is less involved in holding the apparatus, which makes work easier for them. The motor is electrically powered, and this means that the apparatus can be used so long as there is power. This makes it an efficient and reliable apparatus for most Chemistry labs.

Rotary Evaporators Suppress Bumping

Due to the forces that contribute to the evaporation process (centripetal force and friction), bumping is often suppressed. This allows for quick and gentle evaporation of mixtures, and therefore allows even the inexperienced users to utilize these apparatus. The solvent remaining after the rotary evaporation can further be removed through a deeper vacuum or a tightly sealed vacuum system at ambient or relatively higher temperatures.

In summary, the advantages of rotary evaporators include lower boiling temperatures, faster evaporation of solvents, fewer operations, and suppression of bumping. These advantages make rotary evaporators an essential tool for many laboratory applications, including chemical synthesis, purification, and analysis. With proper training and experience, laboratory professionals can use rotary evaporators to achieve accurate, reliable, and efficient results in their work.

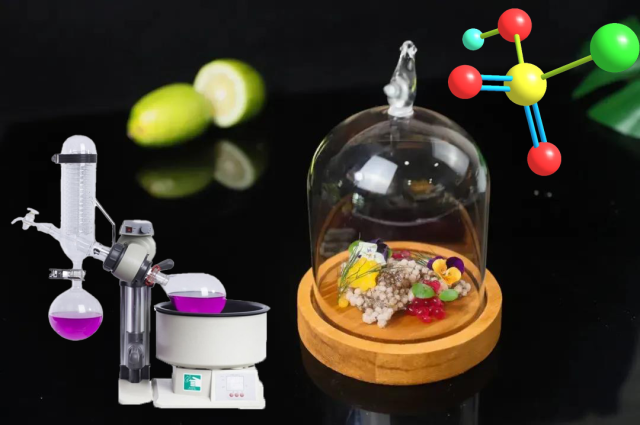

Rotary Evaporation in Molecular Cooking

Rotary evaporation has been a widely used technique in chemical laboratories for separating solvents and removing liquid from samples. However, its use has now expanded beyond the boundaries of chemistry and pharma. In recent years, celebrated chefs have been using rotary evaporators in their kitchens to create unique and flavorful dishes. This application of rotary evaporation in cooking is known as molecular cooking, a style of cuisine that emphasizes scientific experimentation and innovation.

What is molecular cooking?

Molecular cooking, also known as molecular gastronomy, is a culinary style that combines scientific principles with cooking techniques to create unique and innovative dishes. This style of cooking involves using scientific equipment and techniques, such as rotary evaporation, to create new flavors, textures, and presentations.

Rotary evaporation in molecular cooking

Rotary evaporation has become a crucial tool in molecular cooking, allowing chefs to extract and concentrate flavors from a variety of foods, including oils, purées, sauces, and juices. By using rotary evaporation to extract and concentrate flavors, chefs can create intense and complex tastes that cannot be achieved through traditional cooking methods. Additionally, rotary evaporation can be used to create infused oils and spirits, adding a new dimension to cocktails and other beverages.

The process of rotary evaporation in molecular cooking

The process of rotary evaporation in molecular cooking involves gently heating a mixture of food and alcohol in a rotary evaporator, which is a device that creates a vacuum to lower the boiling point of the liquid. The vacuum also helps to prevent the mixture from boiling over and losing its flavor. The mixture is then rotated at a slow speed to increase the surface area of the liquid, allowing it to evaporate more easily.

As the liquid evaporates, it is collected in a separate container, leaving behind a concentrated mixture of flavors and aromas. This concentrated mixture can be used to add flavor to a variety of dishes, such as soups, sauces, and desserts.

Conclusion

Rotary evaporation has become an essential tool for chefs who want to create unique and flavorful dishes. By using this technique, chefs can extract and concentrate flavors from a variety of foods, creating intense and complex tastes that cannot be achieved through traditional cooking methods. With the proper training and practice, anyone can learn to use rotary evaporation in molecular cooking to create unique and delicious culinary creations.

Applications of Rotary Evaporators in Industries

Rotary evaporators are versatile laboratory equipment widely used in various industries such as pharmaceuticals, food and beverage, and chemical manufacturing, among others. The technique involves separating liquid mixtures based on their boiling points. Here are some of the applications of rotary evaporators in industries:

Pharmaceutical Industry

In the pharmaceutical industry, rotary evaporators are used to isolate and purify active compounds from natural products or synthetic mixtures. This process is essential for producing pure and effective drugs and other medical substances.

Food and Beverage Industry

Rotary evaporators are used to concentrate flavors and aromas in the food and beverage industry. This process is used to enhance the taste and aroma of different food products, including juices, soups, and other dishes.

Chemical Manufacturing

Rotary evaporators are used to recover solvents from reaction mixtures or for the concentration of final products in chemical manufacturing. The technique is efficient in separating and purifying chemical substances, making it an essential tool in the industry.

Cannabis Extraction

Rotary evaporators are widely used in the cannabis industry to extract CBD, which is the main component of marijuana. The technique is essential for producing pure CBD used in the production of medical marijuana.

Molecular Cooking

Rotary evaporators are also used in the cooking industry, specifically in molecular cooking. The process applies the principles of chemistry and physics to cooking, making it a perfect combination of modern culinary and experimental instruments. The use of rotary evaporators to non-heat evaporate liquid retains volatile aromatics that are easily lost by heating, enhancing the cooking skill.

In conclusion, rotary evaporators are essential tools for any industry that requires the separation and purification of liquids. With proper training and experience, professionals can master the art of rotary evaporation, opening up a world of possibilities for the separation and purification of liquids.

How Rotary Evaporators Work

Rotary evaporation is a crucial technique used in laboratories to purify and isolate substances from mixtures. This process involves heating a solution under vacuum and leaving behind the desired substance. The machines used to carry out this procedure are known as rotary evaporators, also called rotovaps.

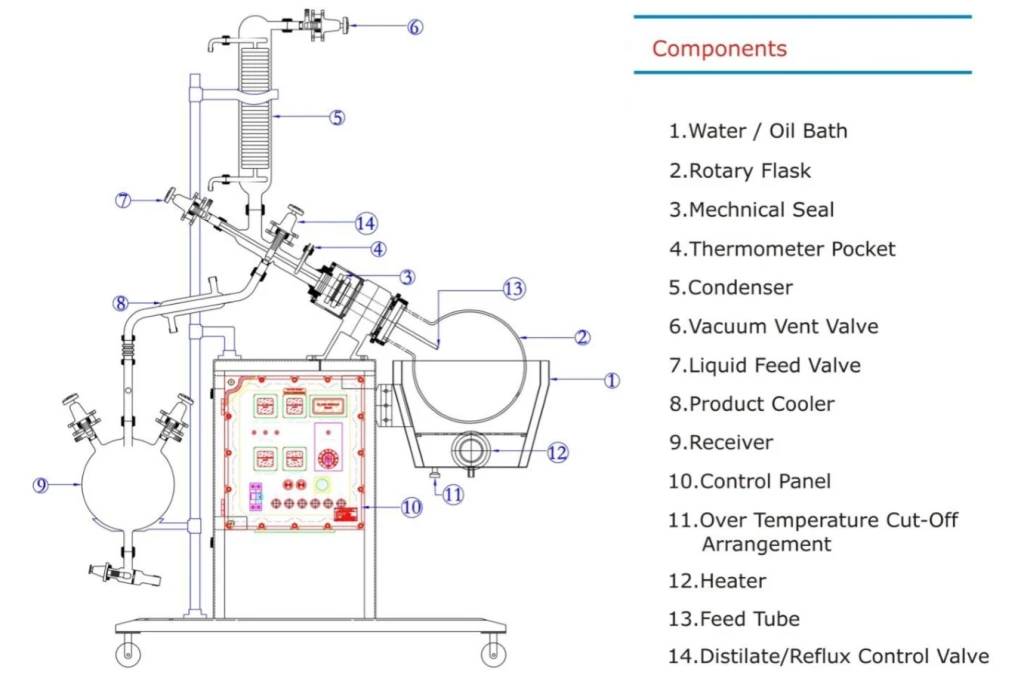

The Components of a Rotary Evaporator

Rotary evaporators consist of four main components: a flask, a condenser, a vacuum pump, and a rotating motor. The flask is filled with the solution, and the vacuum pump creates a low-pressure environment, allowing the solution to evaporate at a lower temperature. The rotating motor spins the flask, increasing the surface area of the solution and speeding up the evaporation process. The condenser then cools and condenses the vapors, which are collected in a separate flask.

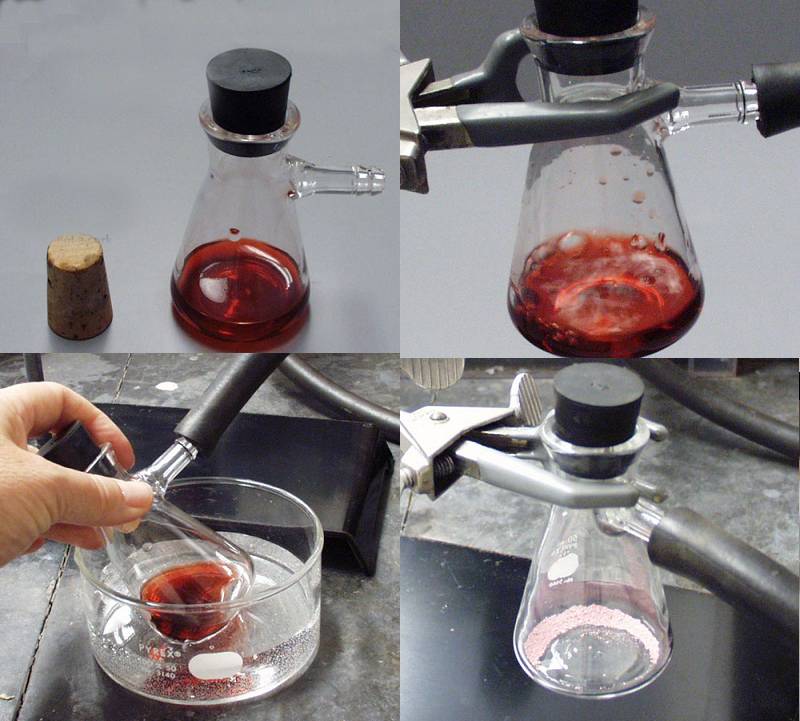

The Process of Rotary Evaporation

Rotary evaporation works on the principle that solvents have a range of boiling points, which decrease under reduced pressure. The evaporation flask rotates at a specified speed, forcing the materials to form a large area of thin film on the inner wall of the flask. The flask is heated evenly, and materials with a lower boiling point rapidly evaporate. Recycling of the solvent stream occurs in the receiving flask, following cooling by the glass condenser.

Importance of Temperature and Pressure Control

The key to mastering the art of rotary evaporation is understanding the importance of temperature and pressure control. The temperature must be carefully monitored, as too much heat can cause the desired substance to decompose or evaporate too quickly. Pressure control is important as well, as too low of a pressure can cause bumping and too high of a pressure can result in a slower evaporation rate.

Benefits of Using a Rotary Evaporator

Users can carry out solvent removal faster and more efficiently than evaporation under atmospheric pressure, thus saving time and increasing productivity in the laboratory. In part, this accelerated evaporation is due to the film’s formation on the flask’s inner surface, which increases evaporation significantly. Rotary evaporators are simple to use and are commonly found in laboratories.

Factors to Consider When Selecting a Rotary Evaporator

One of the most critical considerations for rotary evaporator selection is solvent type. Understanding the properties of solvent is beneficial as it informs the user about the total vacuum required. Monitoring low boiling points is essential so that the bath temperature does not exceed these temperatures. It is vital to consider heating and cooling capacity. The temperature difference between the solvent solution and the condenser must be sufficient. Tailoring automation and accessories can ensure streamlined workflow when using rotary evaporators. Certain automated features such as motorized lifts and automatic boiling point detection can minimize operational time.

In conclusion, rotary evaporation is a highly effective and efficient method for purifying and isolating substances in laboratory settings. By understanding the process of rotary evaporation and the importance of temperature and pressure control, users can achieve optimal results when using rotary evaporators.

Benefits of Using a Rotary Vacuum Evaporator

Rotary vacuum evaporators offer several benefits that enhance the efficiency, precision, versatility, scalability, and safety of the technique. Here are some of the most important benefits of using a rotary vacuum evaporator:

Efficient and Rapid Evaporation

A rotary vacuum evaporator allows for efficient and rapid evaporation of solvents, which saves time and increases productivity. The rotating motion creates a thin film of the solvent on the surface, which increases the surface area for evaporation. The vacuum pump lowers the pressure, which enhances the evaporation rate and prevents the solvent from boiling at high temperatures.

Gentle and Precise Technique

Rotary vacuum evaporation is a gentle and precise technique that does not damage delicate compounds and preserves their integrity. It is ideal for heat-sensitive compounds that can be easily decomposed or deteriorated at high temperatures.

Versatility

Rotary vacuum evaporation is a versatile technique that can be used for a wide range of solvents, including volatile and temperature-sensitive ones. It is suitable for both small-scale and large-scale operations, making it a scalable technique.

Safe Technique

Rotary vacuum evaporation is a safe technique that minimizes the exposure of laboratory personnel to toxic solvents and vapors. The vacuum pump lowers the pressure, which reduces the boiling point of the solvent and prevents it from boiling at high temperatures. This reduces the risk of accidents and ensures the safety of laboratory personnel.

Improved Solvent-Product Separation

Using a rotary vacuum evaporator leads to improved solvent-product separation thanks to the controlled and even evaporation rate. This also decreases the risk of bumping, which can lead to your sample splashing out of the flask.

Visual Monitor and Adjust

Rotary vacuum evaporation allows visual monitor and adjustment. A rotary vacuum evaporator consists of transparent glass hardware, which allows the user to visually see the completion of the evaporation and eliminates the guesswork. This ensures the accuracy of the results and reduces the risk of error.

In conclusion, using a rotary vacuum evaporator offers numerous benefits that enhance the efficiency, precision, versatility, scalability, and safety of the technique. It is a valuable tool in the arsenal of laboratory equipment that can facilitate the separation, purification, and concentration of solvents in various applications, such as chemical synthesis, drug discovery, and food analysis.

Innovations in Rotary Evaporation Technology

Rotary evaporation is a widely used technique in laboratory settings for separating and purifying compounds from mixtures. In recent years, there have been significant advancements in rotary evaporation technology that have revolutionized the process.

Automated Systems

One innovation in rotary evaporation technology is the use of automated systems that can be programmed to control temperature, vacuum pressure, and rotation speed. This allows for more precise and efficient evaporation, saving time and improving accuracy. Automated systems also reduce the risk of errors caused by human intervention.

Digital Displays

Another advancement is the use of digital displays that provide real-time feedback on key parameters, allowing operators to make adjustments quickly and easily. This feature is especially helpful in applications that require precise control of temperature and pressure. Digital displays also help in recording data and analysis.

Improved Materials and designs

The use of new materials and designs in the construction of rotary evaporators has led to improved durability and longevity, reducing the need for costly repairs and replacements. For instance, the use of PTFE (Polytetrafluoroethylene) in the construction of feed tubes has increased chemical compatibility and durability. Likewise, the use of advanced materials like stainless steel in the construction of the evaporator flask has improved resistance to corrosion and wear.

Integration with other technologies

Advancements in rotary evaporation technology have led to integration with other technologies to create more efficient and accurate systems. For example, combining rotary evaporation with freeze-drying technology has led to the development of rotary evaporator freeze dryers. This combination allows for more efficient solvent removal and drying of samples.

In conclusion, the latest rotary evaporation technology offers a range of benefits that can streamline workflows and improve the quality of data generated. Innovations such as automated systems, digital displays, improved materials and designs, and integration with other technologies have made it easier than ever for laboratory professionals to master the art of rotary evaporation and achieve reliable, reproducible results.

KINTEK Rotary Evaporation Advantage

Rotary evaporation is a crucial technique for the effective separation and concentration of solvents from various samples in the laboratory. KINTEK rotary evaporators are a popular choice in the market, known for their high-performance features and superior quality. In this section, we will discuss the KINTEK Rotary Evaporation Advantage in detail.

Advanced Technology

The KINTEK Rotary Evaporation Advantage lies in its advanced technology, which includes precision temperature control, automatic lift system, and highly efficient condenser design. These features ensure a rapid and accurate evaporation process, leading to faster sample processing times and high-quality results.

User-Friendly Interfaces

KINTEK rotary evaporators are designed with user-friendly interfaces and intuitive controls, making them easy to use even for beginners. The instruments are equipped with digital displays that show the status of the evaporation process, and the control knobs allow users to adjust the settings easily.

Wide Range of Models

KINTEK offers a wide range of rotary evaporators to fit different laboratory needs and budgets, ensuring that every user can find the best equipment for their specific requirements. The portfolio contains many different sizes and configurations, including benchtop rotary evaporators and scale-up rotary evaporators that can accommodate 10-200L of evaporation.

Exceptional Versatility and Reliability

KINTEK rotaries offer exceptional versatility, reliability, and energy efficiency. The designs include multiple patented features that enable better mixing, resulting in improved heat transfer and mass transfer. The absence of moving parts in the tube support system provides a simple, reliable, robust design that enhances scalability. Additionally, the tumbling action of the product within the tube results in high degrees of temperature uniformity and gas-solid contact, producing a more homogenous product, reducing processing times, and increasing production rates.

Customizable Accessories

KINTEK also offers a range of accessories to customize the instrument and enhance its functionality. For example, the instruments can be paired with a range of chillers and automation features to improve the evaporation process further.

In conclusion, the KINTEK Rotary Evaporation Advantage is a combination of advanced technology, user-friendly interfaces, wide range of models, exceptional versatility and reliability, and customizable accessories. These features make KINTEK rotary evaporators an excellent choice for any laboratory looking to improve their rotary evaporation process and achieve accurate and efficient results.

Conclusion: Mastering the Art of Rotary Evaporation

In conclusion, mastering the art of rotary evaporation requires an understanding of the technology, process, and applications. Rotary evaporators offer several advantages, including efficiency, versatility, and precision. These devices are widely used in molecular cooking, chemical, pharmaceutical, and other industries. Advances in rotary evaporation technology have led to the development of more innovative, automated, and user-friendly instruments. KINTEK rotary evaporators, for instance, offer unique advantages such as intelligent temperature control, real-time monitoring, and automatic lift. By mastering the art of rotary evaporation, you can improve your laboratory processes, optimize your yields, and enhance your product quality.