Selection and Performance of Graphite Rods

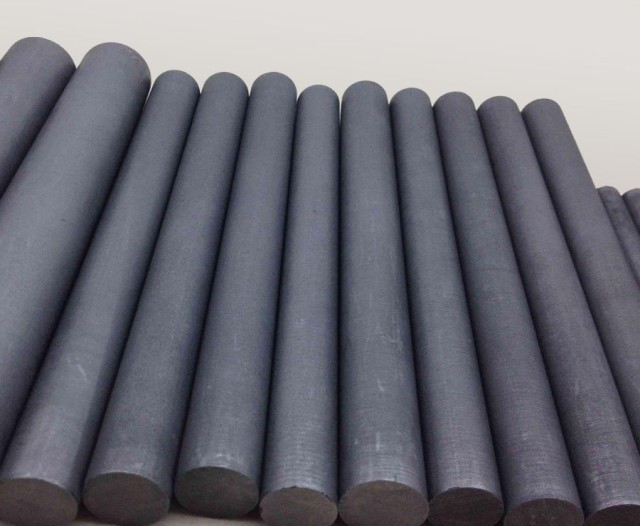

Uniformity

The uniformity of graphite rods plays a pivotal role in maintaining a consistent temperature distribution within the vacuum sintering furnace. This uniformity is not merely a byproduct of manufacturing but a critical attribute that directly influences the efficiency and effectiveness of the sintering process. High-purity graphite rods, characterized by their uniform texture, are essential in mitigating temperature discrepancies within the furnace.

To illustrate the importance of uniformity, consider the following factors:

- Material Purity: Graphite rods with high carbon content ensure minimal impurities, which can cause localized heating effects. This purity is crucial for maintaining a stable temperature across the furnace.

- Texture Consistency: A uniform texture in graphite rods prevents hotspots and cold spots, which can lead to uneven sintering. This consistency is achieved through precise manufacturing processes that control the grain size and distribution of graphite particles.

| Aspect | Importance |

|---|---|

| Material Purity | Minimizes localized heating, ensuring a stable temperature distribution. |

| Texture Consistency | Prevents hotspots and cold spots, promoting even sintering. |

Ensuring the uniformity of graphite rods is not just about achieving a homogenous product; it is about optimizing the entire sintering process. By selecting high-purity, uniformly textured graphite rods, manufacturers can significantly reduce the risk of uneven temperature distribution, thereby enhancing the quality and reliability of the final product.

Resistance to Oxidation

Graphite rods, when heated, naturally form a protective silica film that shields them from oxidation. This silica layer acts as a barrier, preventing the rods from degrading due to exposure to air. However, the integrity of this protective film is compromised in vacuum environments, where the absence of air molecules allows for more direct interactions with the graphite surface.

In vacuum sintering furnaces, maintaining the stability of the furnace environment is crucial. Prolonged exposure to air can lead to the degradation of the silica film, rendering the graphite rods susceptible to oxidation. To mitigate this risk, it is essential to ensure that the furnace operates under stable conditions, minimizing fluctuations that could inadvertently introduce air into the vacuum chamber.

Additionally, regular monitoring and maintenance of the furnace's vacuum integrity are necessary. Any breach in the vacuum can expose the graphite rods to atmospheric conditions, accelerating the breakdown of the protective silica layer. By adhering to these precautions, the longevity and performance of the graphite rods can be significantly enhanced, ensuring consistent and reliable operation of the vacuum sintering furnace.

Coefficient of Thermal Expansion

The coefficient of thermal expansion (CTE) of graphite rods is a critical parameter that directly influences their performance in vacuum sintering furnaces. This coefficient, which measures the degree of expansion or contraction of the material with changes in temperature, is closely tied to the carbon content within the graphite. High-carbon graphite typically exhibits a higher CTE, whereas low-carbon graphite has a lower CTE.

When selecting graphite rods for a vacuum sintering furnace, it is imperative to consider the working temperature range of the furnace. For instance, if the furnace operates at extremely high temperatures, a graphite rod with a lower CTE might be more suitable to prevent excessive expansion that could lead to stress against the furnace walls. Conversely, for lower temperature operations, a rod with a higher CTE might be acceptable without causing significant structural issues.

To illustrate, consider a scenario where the furnace operates between 1000°C and 2000°C. In this range, a graphite rod with a CTE of 0.9 to 1.2 µm/m·K would be ideal to maintain structural integrity and prevent undue stress on the furnace walls. However, if the furnace operates at a higher temperature range, say 1500°C to 2500°C, a graphite rod with a CTE of 0.5 to 0.8 µm/m·K might be necessary to avoid potential damage.

| Furnace Temperature Range | Ideal CTE Range (µm/m·K) |

|---|---|

| 1000°C - 2000°C | 0.9 - 1.2 |

| 1500°C - 2500°C | 0.5 - 0.8 |

Selecting the appropriate graphite rod based on its CTE ensures not only the longevity of the rod itself but also the overall efficiency and safety of the vacuum sintering process. Therefore, understanding and accurately assessing the CTE of graphite rods is a fundamental step in the selection process for any vacuum sintering furnace application.

Installation and Use of Graphite Rods

Surface Flatness

The surface quality of graphite rods is a critical factor in their performance within vacuum sintering furnaces. A smooth surface, free from obvious roughness, is essential to minimize friction between the rods and the furnace walls. This not only enhances the efficiency of heat transfer but also reduces the risk of ablation, where the graphite material could gradually erode over time.

To achieve optimal surface flatness, several factors must be considered:

- Manufacturing Precision: The production process of graphite rods should ensure high precision to achieve a uniform surface. Any deviations can lead to uneven heat distribution and increased wear.

- Post-Processing: After manufacturing, additional surface treatments may be necessary to remove any minor imperfections that could affect performance.

- Inspection Standards: Rigorous inspection standards should be in place to ensure that each rod meets the required surface flatness specifications before installation.

By maintaining a smooth surface on graphite rods, the overall efficiency and longevity of the vacuum sintering process can be significantly improved.

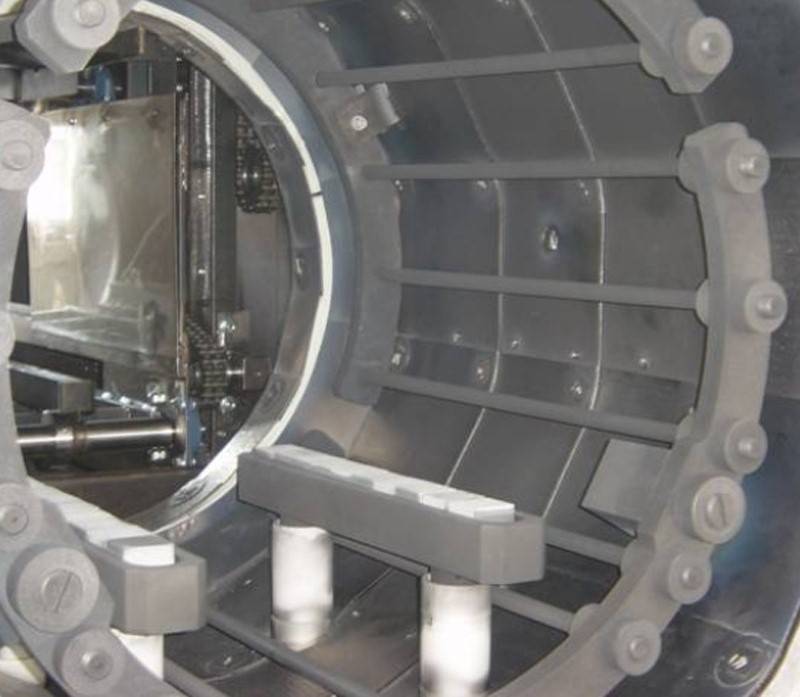

Gap Control

Maintaining an appropriate gap between the graphite rods and the furnace wall is crucial for several reasons. This gap serves as a buffer zone that prevents direct contact between the graphite rods and the furnace walls, thereby mitigating the risk of physical damage to both components. Direct contact can lead to abrasion, which not only shortens the lifespan of the graphite rods but also compromises the integrity of the furnace walls.

Moreover, the gap plays a pivotal role in ensuring uniform heat transfer throughout the furnace. When the graphite rods are positioned correctly with the recommended gap, the thermal energy is distributed more evenly, leading to consistent sintering conditions. This uniformity is essential for achieving high-quality sintering results, as uneven heat distribution can result in inconsistencies in the final product.

The size of the gap is not arbitrary; it is determined by factors such as the thermal expansion properties of the graphite rods and the operational temperature range of the furnace. As the furnace heats up, the graphite rods expand, and a well-calculated gap accommodates this expansion without causing undue stress or deformation. Conversely, if the gap is too large, it can lead to inefficient heat transfer and potential hot spots within the furnace, which can adversely affect the sintering process.

In summary, the judicious control of the gap between the graphite rods and the furnace wall is a critical aspect of the installation and operation of vacuum sintering furnaces. It not only safeguards the integrity of the components but also optimizes the heat transfer process, ensuring uniform and effective sintering.

Regular Inspection and Replacement

Graphite rods are not immune to the effects of prolonged use; they undergo wear and aging, which can significantly impact their performance. Therefore, it is imperative to implement a rigorous inspection schedule to monitor their condition. Regular inspections should be conducted to identify any signs of damage, such as cracks, fractures, or significant wear. Additionally, performance metrics should be evaluated to ensure that the rods are still capable of maintaining the necessary temperature uniformity and resistance to oxidation.

When a graphite rod is found to be damaged or its performance has declined, prompt replacement is crucial. Delaying the replacement of a compromised rod can lead to uneven heating within the furnace, which may affect the quality of the sintering process. Furthermore, a deteriorated rod may pose safety risks, such as the potential for breakage or failure during operation.

To streamline the inspection and replacement process, it is advisable to establish a standardized checklist. This checklist should include visual inspections, performance tests, and documentation of any observed anomalies. By adhering to a structured approach, maintenance teams can ensure that all graphite rods are in optimal condition, thereby extending the lifespan of the rods and maintaining the overall efficiency and safety of the vacuum sintering furnace.

Other Preventive Measures

Current Control

The current passing through the graphite rod must be meticulously regulated to prevent overheating or potential burning, which can occur due to an excessive current load. This control is crucial as it directly impacts the longevity and efficiency of the graphite rod in a vacuum sintering furnace.

To achieve optimal current control, several factors must be considered:

-

Current Monitoring: Continuous monitoring of the current ensures that it remains within the safe operating range. Modern furnaces often come equipped with advanced sensors and monitoring systems to provide real-time data.

-

Regulation Mechanisms: Automatic or manual regulation mechanisms can adjust the current based on the feedback from the monitoring systems. This dynamic adjustment helps in maintaining a stable and safe current level.

-

Thermal Management: Proper thermal management strategies, such as using heat sinks or cooling systems, can dissipate excess heat generated by the current, thereby preventing overheating.

| Consideration | Importance |

|---|---|

| Current Monitoring | Ensures current remains within safe limits, preventing overheating and burning. |

| Regulation Mechanisms | Allows for dynamic adjustment of current based on real-time data. |

| Thermal Management | Dissipates excess heat, maintaining rod integrity and performance. |

By carefully managing the current and implementing robust monitoring and regulation systems, the risk of graphite rod damage due to excessive current can be significantly mitigated.

Vacuum Maintenance

The vacuum degree within a vacuum sintering furnace plays a pivotal role in the operational efficiency of graphite rods. Ensuring that the vacuum level meets the specified requirements is essential to maintain optimal performance. Factors that contribute to a decline in vacuum levels must be promptly identified and addressed to prevent potential issues.

Regular maintenance of the vacuum pump is crucial for maintaining the desired vacuum level. This includes:

-

Oil Management: Vacuum pumps that rely on oil require regular checks and changes. Dirty or low oil levels can lead to pump damage and malfunction. It is advisable to consult the user manual for the recommended oil type and change frequency.

-

Component Cleaning: Accumulation of dust, dirt, and debris inside the pump can reduce its efficiency. Regularly clean the pump head, motor, and inlet and outlet ports using appropriate cleaning tools.

-

General Maintenance Checks:

- Bolts and Couplings: Regularly check the tightness of mounting bolts and vibration couplings.

- Noise and Vibration: Investigate any unusual noise or vibration to prevent potential issues.

- Guards: Ensure all guards are installed before operating the pump.

- Oil Levels: Monitor oil levels and look for signs of contamination. Change the oil if necessary.

For roughing pumps, additional maintenance items include:

- Pulleys and Belts: Check the tightness of pulleys and belts to ensure proper functioning.

- Exhaust Line Filter: Drain the exhaust line filter daily and ensure proper ventilation.

- Oil Reservoir and Valves: Clean the oil reservoir, valve deck, and solenoid valve every six months.

By adhering to these maintenance practices, the vacuum degree within the sintering furnace can be sustained, thereby ensuring the longevity and efficiency of the graphite rods.

Safe Operation

Ensuring safe operation is paramount when replacing and maintaining graphite rods in vacuum sintering furnaces. This process involves several critical steps to prevent burns and other safety incidents.

First, operators must wear appropriate personal protective equipment (PPE), including heat-resistant gloves and face shields, to protect against the high temperatures and potential sparks. Additionally, the work area should be well-ventilated and free from flammable materials to minimize the risk of fire.

Second, before any maintenance or replacement, the furnace must be properly cooled down to a safe temperature. This cooling period is crucial to prevent accidental burns and to ensure that the graphite rods are handled without causing structural damage due to thermal stress.

Third, when handling the graphite rods, operators should use specialized tools designed for high-temperature environments. These tools help to maintain a secure grip without causing damage to the rods or risking slips that could lead to accidents.

Lastly, a thorough safety briefing should be conducted before any maintenance work begins. This briefing should cover emergency procedures, evacuation routes, and the proper use of safety equipment. Regular training sessions for all personnel involved in the maintenance and replacement of graphite rods are essential to reinforce safety protocols and ensure compliance.

By adhering to these safety measures, the risk of injuries and safety accidents can be significantly reduced, ensuring a safer working environment for all personnel involved in the operation and maintenance of vacuum sintering furnaces.

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- High Purity Pure Graphite Crucible for Evaporation

Related Articles

- Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

- Maximizing Efficiency and Precision with Vacuum Graphite Furnaces

- Why Your Graphite Components Keep Failing—And How to Stop It for Good

- Hydrogen Atmosphere Furnaces: Applications, Safety, and Maintenance

- Unveiling Vacuum Graphite Furnaces: Performance, Applications, and Expert Insights