Applications and Importance of Alumina Crucibles

Usage in Melting and Sintering

Alumina crucibles are indispensable tools in the fields of melting and sintering, playing a crucial role in processing materials that require high temperatures and precise control. These crucibles are extensively utilized in the melting of high-temperature alloys, non-ferrous metals, and the sintering of special ceramics and rare earth phosphors. The versatility of alumina crucibles lies in their ability to withstand the extreme conditions required for these processes, ensuring that the integrity and quality of the materials are maintained.

In the context of sintering, alumina crucibles facilitate the binding of metal particles without the need for melting temperatures, making them ideal for metals with high melting points. This process is particularly beneficial in 3D printing technologies, where sintering allows for more controlled and uniform layering of metals, albeit with the trade-off of potentially leaving microscopic gaps. Additionally, sintering can reduce the porosity of an object's surface, enhancing the properties of certain materials.

On the other hand, melting processes benefit from the use of alumina crucibles due to their ability to completely liquefy metal alloys, enabling the reforming of these alloys into new shapes or altering their physical characteristics. This is particularly useful in joining two metals, a process that can sometimes be confused with sintering, especially in advanced techniques like Direct Metal Laser Sintering, where the line between sintering and melting can blur.

The dual application of alumina crucibles in both melting and sintering underscores their importance in high-precision manufacturing, where the demands for both temperature control and material integrity are paramount.

Role in High-Temperature Alloy Precision Casting

High-temperature alloys play a pivotal role in the precision casting of critical components for aero-engines and gas turbines. These alloys are indispensable for manufacturing hot end parts such as working blades, turbine disks, and combustion chambers, which are subjected to extreme thermal and mechanical stresses. The integrity and performance of these components are crucial for the overall efficiency and reliability of aero-engines and gas turbines.

In the context of precision casting, high-temperature alloys are selected for their ability to withstand elevated temperatures without compromising structural integrity. This characteristic is vital for the longevity and operational efficiency of aero-engine and gas turbine parts. The alloys' resistance to thermal degradation ensures that these components can maintain their shape and function under prolonged high-temperature exposure, thereby contributing to the overall performance and safety of the engine.

Moreover, the use of high-temperature alloys in precision casting is not just about durability; it also involves intricate metallurgical considerations. The alloys must be capable of maintaining their microstructural stability under cyclic thermal loading, which is a common scenario in the operation of aero-engines and gas turbines. This stability is essential for preventing fatigue failures, which can lead to catastrophic consequences in aviation and power generation sectors.

The selection and application of these alloys in precision casting processes are further influenced by the properties of the crucibles used in the melting stage. Alumina crucibles, for instance, are preferred due to their high-temperature stability and resistance to chemical reactions with the molten metal. This ensures that the alloys remain pure and free from contamination, which is critical for achieving the desired mechanical properties and performance characteristics.

In summary, high-temperature alloys are the backbone of precision casting for aero-engine and gas turbine components. Their ability to endure extreme conditions while maintaining structural and functional integrity makes them an indispensable asset in the aerospace and energy industries.

Advantages and Properties of Alumina Crucibles

High Temperature Stability

Alumina crucibles are renowned for their exceptional ability to withstand extreme temperatures, making them indispensable in high-temperature alloy melting processes. This high temperature stability ensures that the metal raw materials remain intact and uncompromised throughout the melting process. Unlike other materials that might deform or rupture under such conditions, alumina crucibles maintain their structural integrity, thereby preserving the purity and consistency of the molten metal.

In the context of precision casting, where the integrity of the final product is paramount, this property of alumina crucibles is particularly crucial. The high-temperature environment required for melting alloys used in aerospace components, such as turbine blades and combustion chambers, necessitates a crucible that can endure these extreme conditions without compromising the metal's properties. The ability of alumina crucibles to maintain their shape and resist thermal degradation ensures that the metal remains free from contamination and deformation, which are critical factors in achieving the high standards required for aerospace applications.

Moreover, the high temperature stability of alumina crucibles extends beyond mere durability. It also contributes to the overall efficiency and reliability of the melting process. By ensuring that the crucible remains stable and functional under high temperatures, the process can proceed smoothly without interruptions or the need for frequent replacements, thereby enhancing productivity and reducing operational costs.

In summary, the high temperature stability of alumina crucibles is a fundamental property that underpins their widespread use in precision casting. It ensures the integrity of the metal raw materials, supports the stringent requirements of aerospace applications, and enhances the efficiency and reliability of the melting process.

Chemical and Corrosion Stability

Alumina crucibles exhibit exceptional chemical stability, particularly when in contact with most metal melts. This stability is crucial in preventing any unwanted chemical reactions between the melt and the crucible, thereby maintaining the integrity and purity of the molten material. The inert nature of alumina ensures that it can resist corrosion from a wide range of substances, including acidic, alkaline, and neutral melts.

This chemical resilience is not merely a theoretical advantage but a practical necessity in high-temperature alloy precision casting. For instance, in the production of aerospace components like turbine blades and disks, the purity of the metal is paramount. Any contamination from the crucible could lead to defects, compromising the structural integrity and performance of these critical parts.

| Type of Melt | Corrosion Resistance |

|---|---|

| Acidic Melts | High |

| Alkaline Melts | High |

| Neutral Melts | High |

The ability of alumina crucibles to withstand such a diverse array of corrosive environments underscores their versatility and reliability in precision casting processes. This robustness ensures that the crucibles can be used repeatedly without degradation, offering both economic and operational benefits.

Thermal Shock Stability and Mechanical Strength

Alumina crucibles are renowned for their exceptional thermal shock stability and robust mechanical strength, making them indispensable in high-temperature applications. These crucibles can endure rapid and extreme temperature fluctuations without cracking or shattering, ensuring the integrity of the materials being processed. This characteristic is particularly crucial in industries where precision casting requires sudden temperature changes, such as in the aerospace sector.

Moreover, the mechanical strength of alumina crucibles allows them to withstand not only thermal stresses but also physical impacts. This dual capability ensures that the crucibles remain intact during handling and operation, thereby maintaining the purity and consistency of the molten materials. The ability to resist both thermal and mechanical shocks enables these crucibles to perform reliably in demanding environments, contributing to the overall efficiency and success of high-temperature processes.

In summary, the combination of thermal shock stability and mechanical strength in alumina crucibles provides a robust solution for precision casting, ensuring that they can handle the rigorous conditions inherent in high-temperature alloy melting and other critical applications.

Production and Quality Control in Precision Casting

Vacuum Induction Furnace Usage

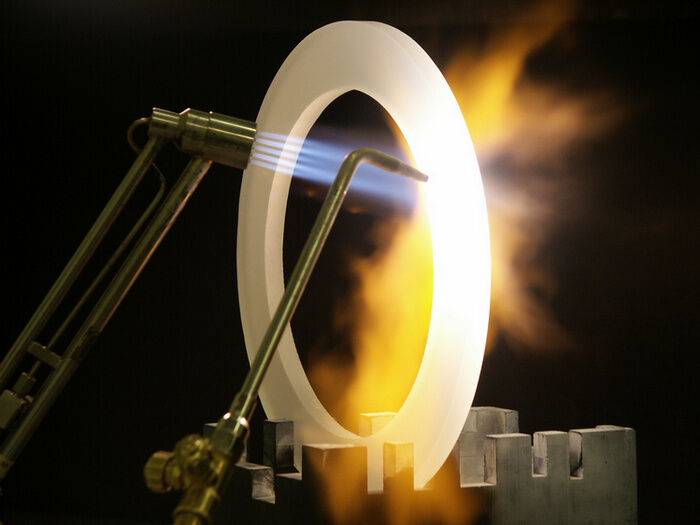

The vacuum induction furnace is a critical tool in the production of high value-added precision castings, particularly in the realm of high-temperature alloys. This furnace operates by melting metal through electromagnetic induction heating within a vacuum environment. The process involves generating eddy currents in the metal via induction coils, which rapidly heat the metal above its melting point. This method offers several distinct advantages, most notably the prevention of secondary oxidation of the molten metal. Due to the absence of oxygen and other gases in the vacuum, the metal is shielded from reactions with atmospheric gases such as oxygen and nitrogen, thereby ensuring the quality and purity of the final product.

The furnace itself is constructed with an air-tight, water-cooled steel jacket designed to withstand the necessary vacuum for processing. The metal is melted in a crucible housed within a water-cooled induction coil, and the furnace is typically lined with suitable refractories to enhance its performance and longevity. The molten metal can be poured or cast either under vacuum or inert gas environments, providing flexibility in the production process.

Additional features found in some vacuum induction furnaces, depending on their size and complexity, may include tilt and pour mechanisms, casting chambers, sampling ports, and mold handling facilities for automated and semi-automated processing. These features often incorporate vacuum interlock systems to further enhance the precision and control of the casting process.

In summary, the vacuum induction furnace's ability to rapidly melt metals at high temperatures while maintaining a vacuum environment makes it an indispensable tool for producing high-quality, high-purity precision castings, particularly in industries requiring high-temperature alloys.

Crucible Material Selection and Impact on Quality

The choice of crucible material significantly influences the molding method, crucible service life, and the purity of high-temperature alloy liquid. Different refractory materials exhibit varying degrees of suitability for smelting conditions due to their distinct physicochemical properties.

Modern crucibles are complex, graphite-based composite materials that rely on precise control over their composition and structural alignment to meet performance requirements. These crucibles come in various sizes, from small teacups to large containers capable of holding several tons of metal. They can be fixed within a furnace or designed for removal during the pouring process. Crucibles are utilized in diverse furnace types, including fuel-fired, electric resistance, and induction furnaces, and they are available in a multitude of shapes and configurations, each tailored to specific applications.

Selecting the right crucible for a particular operation is a nuanced task. Each application presents a unique set of temperature, chemical, and physical parameters that define the operational boundaries for the crucible. For instance, the melting of metal or holding a molten bath requires a crucible that can withstand the specific conditions of that process. The selection process must consider the furnace type, alloy being melted, metallurgical treatments, pouring arrangements, and the end product, ensuring that the chosen crucible maximizes performance and durability.

In summary, the crucible material selection is a critical factor in precision casting, impacting the quality and efficiency of the entire process. The right crucible not only enhances the purity and stability of the molten alloy but also ensures the longevity and reliability of the casting operation.

Challenges and Considerations in Alumina Crucible Usage

Requirement for High Purity and Stability

As high-temperature alloy development has reached a stage where significant adjustments to main components are no longer feasible, the focus has shifted towards meticulous control of impurity elements such as oxygen (O), nitrogen (N), and sulfur (S). These impurities can significantly degrade the performance of high-temperature alloys, particularly in applications demanding extreme durability and stability.

To address this, the production of high-purity or ultra-pure high-temperature alloys has become imperative. This rigorous purification process not only eliminates harmful impurities but also enhances the overall toughness and reliability of the alloys. The significance of this approach is underscored by the critical role these alloys play in high-stakes industries, such as aerospace, where even minor flaws can lead to catastrophic failures.

| Impurity | Harmful Effects | Mitigation Strategies |

|---|---|---|

| Oxygen (O) | Oxidation, embrittlement | Vacuum induction melting, inert gas protection |

| Nitrogen (N) | Formation of nitrides, reduced ductility | Controlled atmosphere furnaces, nitrogen scavengers |

| Sulfur (S) | Formation of sulfides, corrosion | Desulfurization processes, high-purity raw materials |

By adopting these advanced purification techniques, manufacturers can produce high-temperature alloys that meet the stringent requirements of modern precision casting, ensuring superior performance and longevity in high-stress environments.

Correct Operation and Maintenance

Ensuring the correct operation and maintenance of alumina crucibles is crucial for maintaining their longevity and the quality of the products they help create. Different types and specifications of alumina crucibles are designed to cater to various metal melting and precision casting processes. Therefore, selecting the appropriate crucible involves careful consideration of several factors, including the specific process requirements, the type of metal being melted, and the required melting temperature. This selection process is essential to ensure that the crucible can effectively meet the production demands.

In addition to the initial selection, proper operation during use is equally important. Operators must adhere to the correct operational procedures to prevent damage to the crucible and to maintain the integrity of the products being cast. This includes avoiding practices that could compromise the crucible's performance, such as excessive heating, rapid cooling, and rapid heating. These improper operations can lead to thermal shock, which can significantly reduce the crucible's lifespan and potentially affect the quality of the cast products.

To illustrate the impact of improper practices, consider the following scenarios:

| Improper Practice | Potential Consequences |

|---|---|

| Excessive Heating | Cracks and fractures due to thermal stress |

| Rapid Cooling | Thermal shock leading to material degradation |

| Rapid Heating | Uneven expansion causing structural damage |

By adhering to the correct operational guidelines and maintaining a consistent approach to crucible usage, manufacturers can ensure not only the longevity of their alumina crucibles but also the high quality of the precision castings they produce. This attention to detail in both selection and operation underscores the critical role that proper maintenance plays in the overall success of precision casting processes.

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

Related Articles

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

- Choosing the Right Muffle Furnace for Laboratory Needs

- Ceramic Alumina Crucible for Thermal Analysis Test Containers

- Advantages of Mullite Fiber Lining for High-Temperature Furnaces

- The Role of Laboratory Ovens in Scientific Research and Industry