Materials for Calcination

Metallic Materials

High-temperature muffle furnaces are indispensable tools in the metallurgical industry, particularly for processes involving the melting and calcination of various metal materials. These furnaces are capable of handling a wide range of metals, including but not limited to copper, aluminum, iron, and steel. The versatility of these furnaces allows for precise control over the temperature and environment, making them ideal for both research and industrial applications.

For instance, copper, known for its excellent electrical conductivity, is often subjected to high-temperature treatments to enhance its properties. Similarly, aluminum, a lightweight yet strong metal, undergoes calcination to improve its mechanical strength. Iron and steel, fundamental components in construction and manufacturing, also benefit from the controlled heating and cooling processes provided by high-temperature muffle furnaces.

The ability to melt and calcine these metals at elevated temperatures is crucial for refining processes, alloy formation, and the production of specialized materials. This makes high-temperature muffle furnaces indispensable in both industrial production lines and advanced research laboratories.

Ceramic Materials

High-temperature muffle furnaces are indispensable tools in the processing of ceramic materials, particularly for sintering and calcining. These furnaces can handle a diverse array of ceramic materials, including alumina, zirconia, and silicon nitride. Each of these materials presents unique challenges and benefits, making them suitable for different applications within the ceramic industry.

Types of Ceramic Materials

-

Oxide Ceramics: Oxide ceramics, such as alumina and zirconia, are known for their high melting points and excellent thermal stability. They are often used in applications requiring high mechanical strength and resistance to wear and corrosion.

-

Non-Oxide Ceramics: Silicon nitride falls under the category of non-oxide ceramics. These materials are prized for their exceptional thermal shock resistance and high-temperature strength, making them ideal for use in environments where thermal cycling is a concern.

-

Silicate Ceramics: Silicate ceramics, which include clay and kaolin, are the most common type of ceramic materials. They are characterized by their low sintering temperatures and are widely used due to the abundance and low cost of their natural raw materials. However, they generally exhibit lower mechanical properties compared to oxide and non-oxide ceramics.

Sintering Process

The sintering process in high-temperature muffle furnaces is crucial for achieving the desired microstructure and mechanical properties in ceramic materials. This process involves compacting ceramic powder into a solid mass through heat and pressure. The three key stages in this process are:

- Powder Preparation: The quality of the starting powder significantly influences the final properties of the ceramic.

- Pressing: The powder is compacted into a desired shape under high pressure.

- Sintering: The compacted powder is heated in the muffle furnace to a temperature below its melting point, causing it to densify and form a solid piece.

By carefully controlling these stages, it is possible to produce ceramic materials with optimal characteristics for various industrial applications.

Compounds

High-temperature muffle furnaces are versatile tools in the synthesis and calcination of various compounds. These furnaces can facilitate the transformation of raw materials into valuable compounds through controlled heating processes. For instance, the calcination of calcium carbonate (CaCO₃) at elevated temperatures results in the decomposition into calcium oxide (CaO) and carbon dioxide (CO₂). This process is fundamental in industries such as cement production.

Similarly, sodium chloride (NaCl), commonly known as table salt, can undergo thermal decomposition under specific conditions, though this is less common. More typically, sodium chloride is used in conjunction with other compounds to form new substances, such as sodium hydroxide (NaOH) through the chloralkali process.

| Compound | Initial State | Final State | Application |

|---|---|---|---|

| Calcium Carbonate | Solid | Calcium Oxide + Carbon Dioxide | Cement Production |

| Calcium Oxide | Solid | Solid | Construction Materials |

| Sodium Chloride | Solid | Various Compounds | Industrial Chemicals, Food Industry |

The ability to synthesize and calcine such compounds underscores the importance of high-temperature muffle furnaces in both research and industrial settings. These furnaces enable precise control over temperature and atmosphere, making them indispensable for the production of high-purity compounds and the study of their thermal properties.

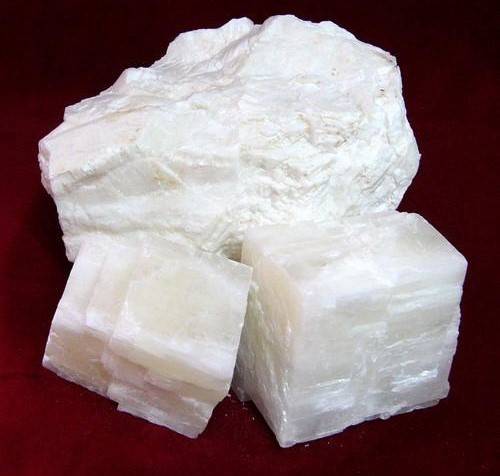

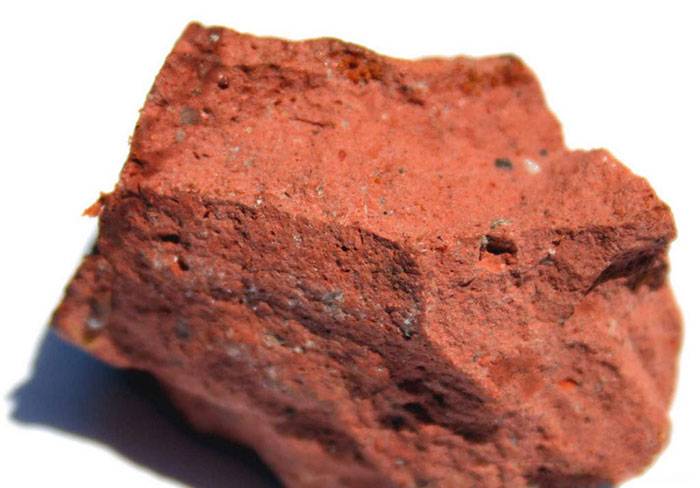

Minerals

High-temperature muffle furnaces are indispensable tools in the calcination process of various minerals. These furnaces can effectively handle a wide array of mineral types, each with unique properties and applications. For instance, bauxite, a primary source of aluminum, undergoes calcination to remove moisture and enhance its reactivity for further processing. Similarly, sulfurous iron ore benefits from calcination to eliminate sulfur content, improving the quality of the resulting iron.

Calcination of minerals like limestone is crucial for producing quicklime, a material widely used in construction and agriculture. This process not only purifies the minerals but also alters their physical and chemical properties, making them more suitable for specific industrial applications. The versatility of high-temperature muffle furnaces in handling diverse mineral types underscores their importance in various industrial and scientific contexts.

High-Temperature Experiments

Scientific Experiments

High-temperature muffle furnaces are indispensable tools in scientific research, particularly in fields like materials science, chemistry, and physics. These furnaces can simulate extreme conditions that are difficult to achieve under normal laboratory settings, making them ideal for a wide range of high-temperature experiments.

In materials science, muffle furnaces are used to study the thermal properties of materials, such as their melting points, phase transitions, and structural changes under elevated temperatures. For instance, the sintering of ceramic materials like alumina and zirconia, which requires temperatures exceeding 1000°C, is a common application.

In chemistry, these furnaces are employed for reactions that necessitate high temperatures, such as the calcination of compounds like calcium carbonate to produce calcium oxide. The controlled environment provided by muffle furnaces ensures that these reactions proceed uniformly and efficiently.

In physics, muffle furnaces are utilized to investigate the behavior of materials at high temperatures, such as the thermal expansion of metals or the degradation of polymers. These experiments often require precise temperature control and uniformity, which muffle furnaces can provide.

Overall, high-temperature muffle furnaces offer a versatile platform for conducting a multitude of experiments across various scientific disciplines, making them a cornerstone of advanced research and development.

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1200℃ Muffle Furnace Oven for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory