Table of Contents

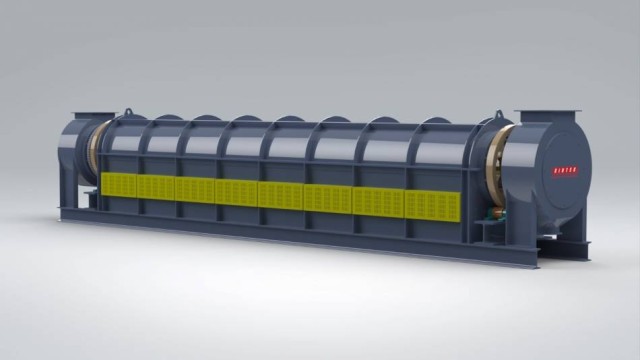

Introduction to Rotary Furnaces

Rotary furnaces are continuous thermal processing systems that utilize rotating tubes to transfer heat to materials. They offer high energy efficiency, flexibility, and versatility, making them suitable for a wide range of applications. Rotary furnaces play a crucial role in advanced materials processing, contributing to the production of ceramics, semiconductors, and metal alloys. Their precise temperature control and uniform heating ensure the desired material properties.

Working Principle and Design

Rotary furnaces are batch furnaces that utilize oxy-fuel burners and limit the volume of off-gases. Their design allows for high utilization of input energy compared to stationary furnaces, making them flexible and suitable for a wide variety of feed materials.

The cylindrical furnace rotates around its axis, featuring a slight tilt to facilitate the movement of materials from one end to the other. This rotation ensures uniform heat distribution and promotes mixing or stirring.

Hot gases flow through the furnace chamber, typically in the opposite direction of the material flow. However, the direction can be adjusted based on application requirements. The furnace is operated by unskilled workers who charge the furnace, smelt it for a predetermined period, and tap the furnace bullion and slag.

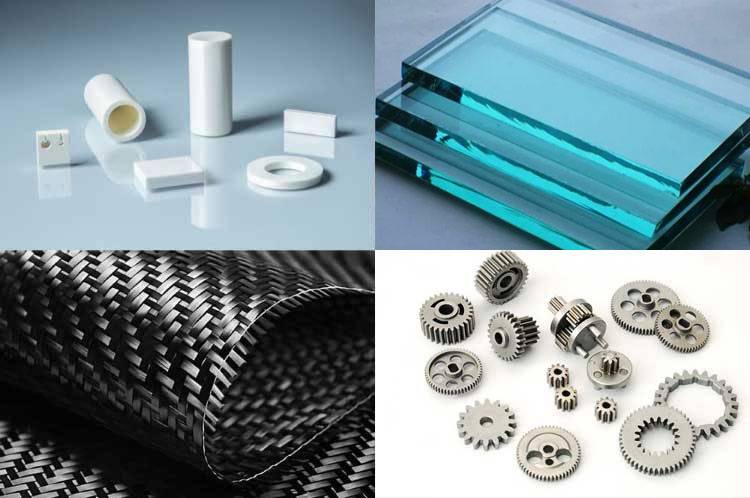

Rotary furnaces are commonly used in the production of non-ferrous metals such as copper, lead, and aluminum. They are also employed in the processing of granular or particulate materials that can flow at high temperatures. These materials include metals, alloys, ceramics, glass, carbon-based materials, oxides, sulfides, nitrides, and carbides.

The furnace can be operated in air or inert atmospheres, depending on the application requirements. Inert atmospheres prevent oxidation or chemical reactions during the heat treatment process.

Advantages of Rotary Furnaces

Compared to conventional furnaces, rotary furnaces offer several advantages, including:

High Production Capacity: Rotary furnaces can process large volumes of material, making them suitable for high-volume production applications.

Efficient Energy Utilization: The design of rotary furnaces allows for efficient heat distribution, reducing energy consumption.

Reduced Emissions: Rotary furnaces effectively capture and control emissions, minimizing environmental impact.

Ease of Operation: Rotary furnaces are designed for user-friendly operation, requiring minimal manual intervention.

Versatile Material Processing: Rotary furnaces can handle a wide range of materials, including battery scraps, blast furnace waste, lead ores, lead dross, and baghouse powder.

Higher Lead Recovery: Compared to blast or fixed furnaces, rotary furnaces achieve higher lead recovery rates.

Environmental Friendliness: Rotary furnaces are designed to minimize emissions, reducing environmental impact.

Reduced Manpower Requirements: Rotary furnaces require less manual labor due to their automated operation.

Tilt Rotary Furnaces: Tilt rotary furnaces offer advantages over conventional static rotary furnaces, including reduced cycle times, higher yields, and lower fuel consumption.

Customizable Options: Rotary furnaces can be customized to meet specific requirements, such as combustion system type, fuel source, and furnace capacity.

Temperature Uniformity: Rotary furnaces provide excellent temperature uniformity, which is crucial for ensuring the quality and consistency of processed materials.

Versatile Applications: Rotary furnaces are used in various applications, including lead recovery from lead-acid batteries, lead sulfate reduction, and ceramic doping with rare earth metals.

Applications in Advanced Materials Processing

Rotary furnaces are extensively utilized in the processing of advanced materials, including the production of ceramics, semiconductors, and metal alloys. They offer precise temperature control and uniform heating, ensuring the attainment of desired material properties.

Material Synthesis and Modification:

Rotary furnaces are employed in the synthesis of various materials, such as alumina, vermiculite, iron ore pellets, and cement clinker. They enable precise control over the heating and cooling processes, allowing for the optimization of material properties and the production of high-quality products.

Oxidation and Roasting:

These furnaces are also used for oxidation, a process that involves the addition of oxygen to a sample, and roasting, a technique employed to induce phase transitions. Rotary furnaces provide controlled heating environments that facilitate these chemical reactions, enabling the modification of material properties and the production of specific compounds.

Ceramic Doping:

Rotary furnaces are versatile equipment that can be utilized for the doping of ceramics with rare earth metals. By introducing small quantities of rare earth elements into ceramic materials, researchers can tailor their physical and chemical characteristics, expanding their range of applications.

Temperature Uniformity:

Temperature uniformity is a crucial factor in rotary furnace operations, as it directly impacts the quality and consistency of the processed materials. Rotary furnaces are renowned for their ability to deliver exceptional temperature uniformity, attributed to the high-quality heating elements employed in their design. This uniform heating ensures consistent material properties throughout the processed batch.

Continuous Processing:

Rotary tube furnaces are ideally suited for manufacturing materials that require continuous throughput of loose materials, such as alumina and iron ore pellets. They are designed to handle high temperatures and provide comprehensive process control, resulting in high-quality products. Applications like calcining, which involves the continuous heating of materials, are well-suited for rotary furnaces.

Operation Principle:

Indirect fired rotary furnaces operate as continuous thermal systems, applying heat to the incoming process material through multiple thermal control zones. Heat is transferred from the heat source, typically gas or electric heating, to a rotating tube containing the process materials and atmospheres. Subsequently, heat is transferred from the tube wall to the material bed undergoing processing. This continuous heating and rotation ensure uniform temperature distribution and efficient material processing.

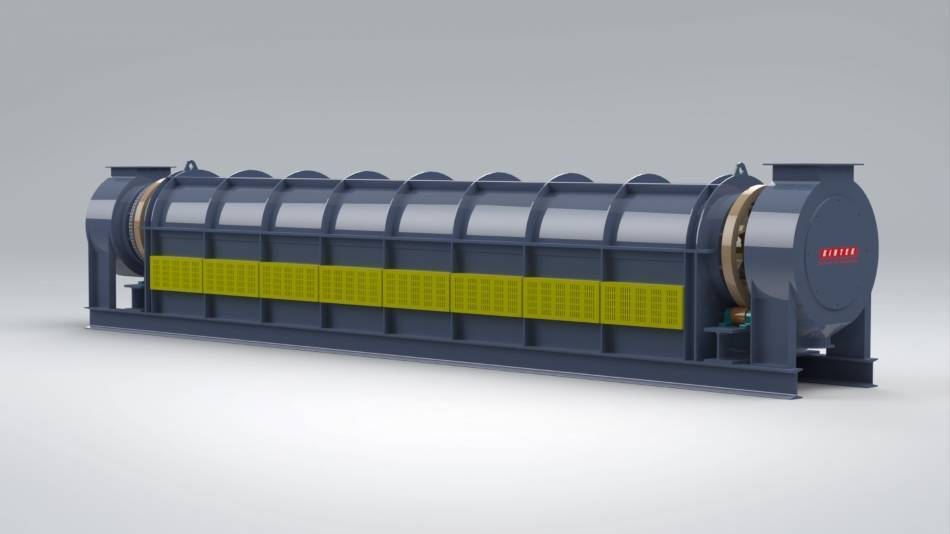

Key Components and Control System

Rotary furnaces are comprised of several key components, including:

- Kiln body: The kiln body is the main structure of the furnace, typically made from steel plate and welded to form a barrel. It can be up to 230 m in length, but the length can vary depending on the application.

- Furnace lining: The furnace lining is a layer of refractory material that protects the kiln body from the high temperatures inside the furnace.

- Drive gear: The drive gear rotates the kiln body, allowing the material inside to move through the furnace.

- Internal heat source: The internal heat source provides the heat necessary to process the material inside the furnace. This can be achieved through various methods, such as gas burners, electric heaters, or microwave energy.

The control system of a rotary furnace is responsible for monitoring and adjusting various parameters, including:

- Temperature: The control system monitors the temperature inside the furnace and adjusts the heat input accordingly to maintain the desired temperature profile.

- Rotation speed: The control system monitors the rotation speed of the kiln body and adjusts the drive gear to maintain the desired speed.

- Atmosphere: The control system can also monitor and adjust the atmosphere inside the furnace, such as the oxygen content or the presence of specific gases.

By precisely controlling these parameters, the control system optimizes the thermal process and ensures the desired product quality.

Environmental Considerations

Rotary furnaces are designed to minimize environmental impact by reducing emissions and energy consumption. They utilize efficient heating systems and incorporate pollution control measures to comply with environmental regulations.

Reduced Emissions

Rotary furnaces use low-emission combustion systems that minimize the release of harmful pollutants into the atmosphere. These systems incorporate advanced burner technologies, such as low-NOx burners, which reduce nitrogen oxide emissions. Rotary furnaces also incorporate flue gas recirculation systems, which recycle exhaust gases back into the combustion chamber, further reducing pollutant formation.

Energy Efficiency

Rotary furnaces are engineered for energy efficiency, reducing operating costs and greenhouse gas emissions. They utilize high-efficiency insulation materials that minimize heat loss. Additionally, regenerative heat exchangers can be incorporated into the furnace design, capturing heat from the exhaust gases and transferring it back to the combustion air, further improving energy utilization.

Compliance with Environmental Regulations

Rotary furnaces meet or exceed stringent environmental regulations, ensuring compliance with local, national, and international emission standards. They incorporate advanced emission control technologies, such as cyclones and bag filters, to capture particulate matter and other pollutants. Rotary furnaces also comply with energy efficiency standards, reducing greenhouse gas emissions and contributing to sustainable manufacturing practices.

Maintenance and Troubleshooting

Regular maintenance and timely troubleshooting are crucial for the optimal performance and longevity of rotary kilns. Here are some key aspects to consider:

Inspection and Monitoring:

- Conduct regular visual inspections to identify any signs of wear, damage, or misalignment.

- Monitor key performance indicators, such as temperature, vibration, and pressure, to detect potential issues early on.

Repairs and Maintenance:

- Address minor repairs promptly to prevent them from escalating into larger problems.

- Perform scheduled maintenance tasks as per manufacturer's recommendations, including:

- Cleaning and lubrication of components

- Replacement of worn or damaged parts

- Calibration and adjustment of systems

- Use high-quality spare parts and materials for repairs to ensure durability and reliability.

Preventive Measures:

- Implement preventive maintenance programs to identify and address potential issues before they occur.

- Utilize predictive maintenance techniques, such as vibration analysis, to identify components at risk of failure.

- Establish a system for regular cleaning and inspection of key areas, such as refractory linings, burners, and seals.

Training and Expertise:

- Ensure that maintenance personnel are adequately trained and experienced in rotary kiln operations and maintenance.

- Involve manufacturers or specialized service providers for complex repairs or troubleshooting.

Troubleshooting Common Issues:

- Refractory Degradation: Inspect and repair refractory linings regularly to prevent thermal damage or chemical corrosion.

- Burner Maintenance: Clean and adjust burners as needed to ensure efficient combustion and prevent flame instability.

- Breeching Seal Wear: Monitor and replace worn breaching seals to prevent air leakage and maintain optimal performance.

- Drum Misalignment: Check and correct drum alignment to ensure smooth operation and prevent excessive wear.

By adhering to these maintenance and troubleshooting guidelines, you can optimize rotary kiln performance, extend its lifespan, and minimize downtime.

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Introducing the Lab Vacuum Tube Furnaces

- Exploring Rotary Tube Furnaces: A Comprehensive Guide

- Electric Rotary Kiln Pyrolysis Furnace: Design, Operation, and Applications

- Advanced Laboratory Furnaces: Box, Muffle, and Tube Options for High-Temperature Applications

- Optimizing Industrial Processes: Rotary Kiln and Laboratory Furnace Solutions