It’s a scenario that’s both baffling and costly. You pull a batch of high-value, precision-engineered components from your vacuum furnace. The cycle report shows the process ran perfectly, hitting the exact target temperature for the exact amount of time. Yet, the parts are ruined. Instead of being perfectly hardened or brazed, they’re brittle, contaminated, or their metallurgical properties are completely off. Weeks of work and thousands of dollars in materials are gone in an instant. You're left staring at the furnace, asking, "What went wrong?"

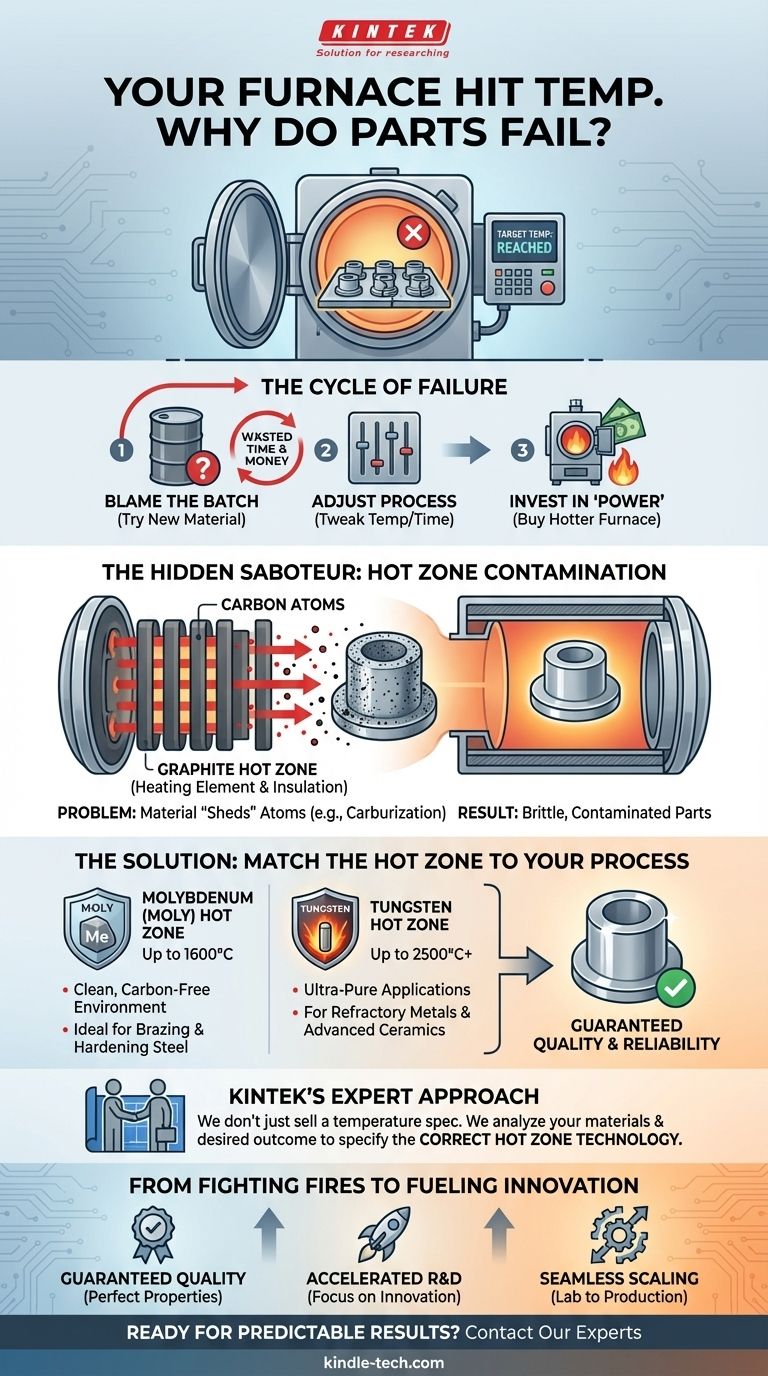

The Cycle of Failure: Why 'Trying Again' Doesn't Work

If this sounds familiar, you're not alone. This is a remarkably common and frustrating problem in materials science and advanced manufacturing. Faced with this unexplained failure, most teams fall into a predictable pattern of troubleshooting:

- Blame the Batch: "Maybe it was a bad batch of raw material." So you try again with a new batch, only to get the same inconsistent result.

- Adjust the Process: "Let's tweak the temperature ramp or hold time." You spend days running slightly different cycles, burning through energy and time, yet the problem persists.

- Invest in More "Power": "Our furnace must not be good enough." A common conclusion is to invest in a furnace with an even higher maximum temperature rating, assuming more power will solve the problem. This often proves to be an expensive mistake that can even make the issue worse.

This cycle of trial and error does more than just waste materials. It creates project bottlenecks, delays product launches, and undermines confidence in your R&D or production capabilities. The real cost isn't just the failed parts; it's the lost time, stalled innovation, and the reputation for unreliability.

The Hidden Saboteur: It’s Not the Heat, It’s the Source

The reason these attempts fail is that they are focused on the wrong variable. The problem isn't usually the temperature you achieve; it's how your furnace generates that heat.

The heart of any vacuum furnace is its "hot zone," which consists of two main components: the heating elements that create the heat and the insulation that contains it. At the extreme temperatures required for processes like sintering or heat-treating advanced alloys, these components are not merely passive bystanders. They can actively interact with your parts.

The Real Culprit: Unwanted Chemical Reactions

Here is the truth that many discover the hard way: the material of your heating element can "shed" atoms and contaminate your product.

A perfect example is graphite. Graphite heating elements are cost-effective, durable, and excellent for reaching very high temperatures (over 2200°C). However, at these temperatures, graphite can release carbon atoms. If you are heat-treating a specific steel or a refractory metal alloy where carbon is an impurity, the furnace itself will poison your parts through a process called carburization. The parts absorb this unwanted carbon, become brittle, and fail.

This is why buying an even hotter graphite furnace can make the problem worse—you're just accelerating the contamination. You're treating the symptom (failed parts) without diagnosing the disease (material incompatibility).

The Right Tool for the Job: Matching the Hot Zone to Your Process

If the root cause is a chemical reaction with the furnace's internal components, then the only real solution is to use a furnace with components that are chemically inert for your specific application.

To truly solve this problem, you need a tool designed with this fundamental principle in mind. This means moving beyond the single metric of "max temperature" and focusing on the composition of the hot zone itself.

For applications sensitive to carbon contamination, the solution is an all-metal hot zone. These furnaces use heating elements and shielding made from materials like Molybdenum (Moly) or Tungsten.

- Molybdenum Hot Zones (up to 1600°C): Ideal for brazing stainless steel or hardening most tool steels, providing a clean, carbon-free environment.

- Tungsten Hot Zones (up to 2500°C+): Required for the most demanding applications, like processing ultra-pure refractory metals or sintering advanced ceramics where any contamination would be catastrophic.

This is precisely where expert guidance becomes critical. KINTEK's role isn't just to sell you a furnace; it's to function as your expert advisor. We don't start with a catalog of temperatures; we start by understanding your process. By analyzing the materials you're working with and your desired outcome, we can specify a furnace with the correct hot zone technology. Our equipment is the embodiment of this problem-solving approach, designed to provide the right environment, not just the right temperature.

From Fighting Fires to Fueling Innovation

Once you stop battling inexplicable failures, you unlock a new level of potential. With a furnace that is correctly matched to your process, you move from uncertainty to absolute reliability.

Imagine what becomes possible:

- Guaranteed Quality: You can confidently process high-value, sensitive materials, knowing their metallurgical properties will be perfect every single time.

- Accelerated R&D: Instead of spending months troubleshooting, your team can focus on genuine innovation and developing the next generation of materials and products.

- Seamless Scaling: The process you perfect in the lab will translate flawlessly to production, eliminating the bottlenecks that hinder growth.

Resolving this fundamental issue transforms your lab or production line from a source of frustration into an engine for reliable, repeatable excellence.

Your work is too important for guesswork. If you're tired of fighting with your equipment and are ready for predictable, high-quality results, it's time for a different conversation. Let's move beyond a simple temperature spec and talk about the specific demands of your projects. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

Related Articles

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good