You know the feeling. The furnace cycle completes, the door opens, and your heart sinks. The complex, high-value part you’ve spent days preparing—the one destined for an aerospace assembly or a medical implant—is flawed. Again. Maybe it’s a discolored, oxidized surface. Maybe the brazed joint is weak and brittle.

The part is a write-off. The clock is ticking on the project deadline. And you’re left staring at a very expensive oven, wondering what went wrong this time.

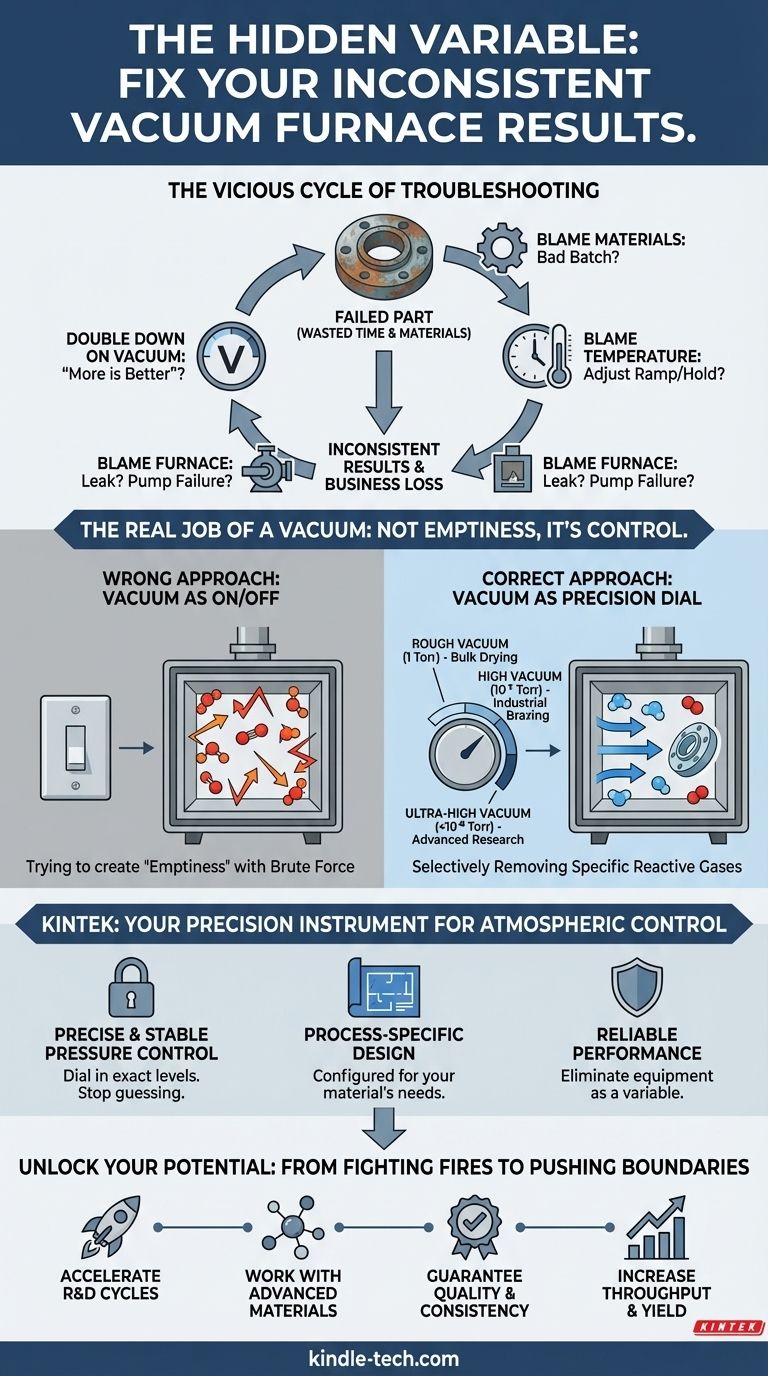

The Vicious Cycle of Troubleshooting

This scenario is frustratingly common in labs and production facilities everywhere. When a thermal process in a vacuum furnace fails, a familiar and often fruitless ritual begins:

- You blame the materials: "Did the supplier send a bad batch of alloy?"

- You blame the temperature: "Should we adjust the ramp rate? Add another ten minutes to the hold time?"

- You blame the furnace itself: "Is there a leak? Is the pump failing?"

- You double down on the vacuum: "Let's just pull a deeper vacuum next time. That has to get rid of whatever is causing this."

So you run the tests again. You tweak the parameters. You spend hours, sometimes days, pumping the chamber down to an even lower pressure, believing that "more vacuum" is always the answer. Yet the results remain unpredictable.

These repeated failures aren't just a technical headache; they have severe business consequences. Each failed run wastes expensive materials, consumes costly energy and man-hours, and pushes project timelines further back. For a business, this translates into delayed product launches, budget overruns, and a damaged reputation for quality and reliability.

The problem is, these troubleshooting steps are all focused on the symptoms. The real root cause is almost always a fundamental misunderstanding of what a vacuum is actually for.

The Real Job of a Vacuum: It's Not Emptiness, It's Control

We tend to think of a vacuum as "empty space." The common logic follows that if we just remove everything from the chamber, our process will be pure. But this is a misleading simplification.

The primary job of a vacuum is not to create emptiness; it is to create a precisely controlled atmosphere.

At the high temperatures inside a furnace, the seemingly harmless air we breathe becomes a cocktail of aggressive chemical agents. Oxygen molecules are eager to oxidize your pristine metal surfaces. Trace amounts of water vapor can interfere with critical reactions.

A vacuum's purpose is to selectively remove these specific, reactive gases. It's a tool for atmospheric control. This is the crucial turning point:

The common mistake is treating vacuum pressure like an on/off switch. The correct approach is to treat it like a precision dial.

Different processes and materials are sensitive to different contaminants.

- A simple drying process may only require a rough vacuum (e.g., 1 Torr) to remove bulk water vapor.

- A standard industrial brazing process needs a high vacuum (e.g., 10⁻⁵ Torr) to prevent oxidation and ensure a clean bond.

- Advanced research on highly reactive metals might demand an ultra-high vacuum (UHV, below 10⁻⁸ Torr) to eliminate virtually every stray molecule.

Pulling a UHV-level vacuum for a simple brazing job is like using a surgical laser to cut a birthday cake. It’s wildly inefficient, dramatically increases cycle time, and drives up operational costs for no added benefit. Conversely, using a rough vacuum when a high vacuum is needed guarantees failure, because you’ve left the "chemical attackers" in the chamber.

The common troubleshooting methods fail because they ignore this principle. They are trying to solve a problem of precision with a tool of brute force.

Choosing Your Instrument: From Sledgehammer to Scalpel

To escape this cycle of failure, you don't need "more vacuum." You need the right vacuum, delivered with precision and repeatability, every single time. This requires a tool designed not just to remove air, but to give you absolute command over the internal environment.

This is precisely the design philosophy behind KINTEK's modern vacuum furnaces. They are not simply insulated boxes with a pump attached; they are high-precision instruments engineered to embody this scientific understanding.

A KINTEK furnace provides the critical capability that solves the root problem:

- Precise and Stable Pressure Control: Our systems allow you to dial in the exact vacuum level your specific process requires—from a rough vacuum to UHV—and hold it there with unwavering stability throughout the heating cycle. You stop guessing and start engineering your atmosphere.

- Process-Specific Design: Whether you need to backfill with a high-pressure inert gas for rapid quenching or maintain a pristine high vacuum for sintering, our furnaces are configured to provide the exact environmental controls your material demands.

- Reliable Performance: By eliminating leaks and using high-performance pumping systems, KINTEK furnaces remove the variable of "Is the equipment working?" so you can focus on perfecting your process.

Our furnaces are the scalpel you need. They are designed to give you the control to remove only what’s necessary, ensuring a perfect, predictable outcome.

From Fighting Fires to Pushing Boundaries: What a Controlled Process Unlocks

When you finally gain reliable control over your thermal processing environment, the entire dynamic of your work changes. The focus shifts from reactive problem-solving to proactive innovation.

Instead of re-running failed experiments, your team can now:

- Accelerate R&D Cycles: Move confidently from one successful test to the next, drastically shortening the time it takes to validate new materials and processes.

- Work with Advanced Materials: Explore the use of more sensitive, reactive alloys and ceramics, knowing you can create the pristine environment they require.

- Guarantee Quality and Consistency: Move a process from the lab to production with the assurance that every part will meet specification, enhancing customer trust and your company’s reputation.

- Increase Throughput and Yield: Eliminate wasted runs, maximizing the productivity of your equipment and the output of your facility.

Solving the "inconsistent results" problem doesn't just fix a technical annoyance. It unlocks your lab's or your production line's true potential.

Your process is unique, and the challenges you face require more than a one-size-fits-all solution. If you're ready to stop troubleshooting and start achieving flawless, repeatable results, our team is here to help you analyze your process requirements and identify the right tool for the job. Our experts are ready to help you match the right technology to your specific project goals. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

Related Articles

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum