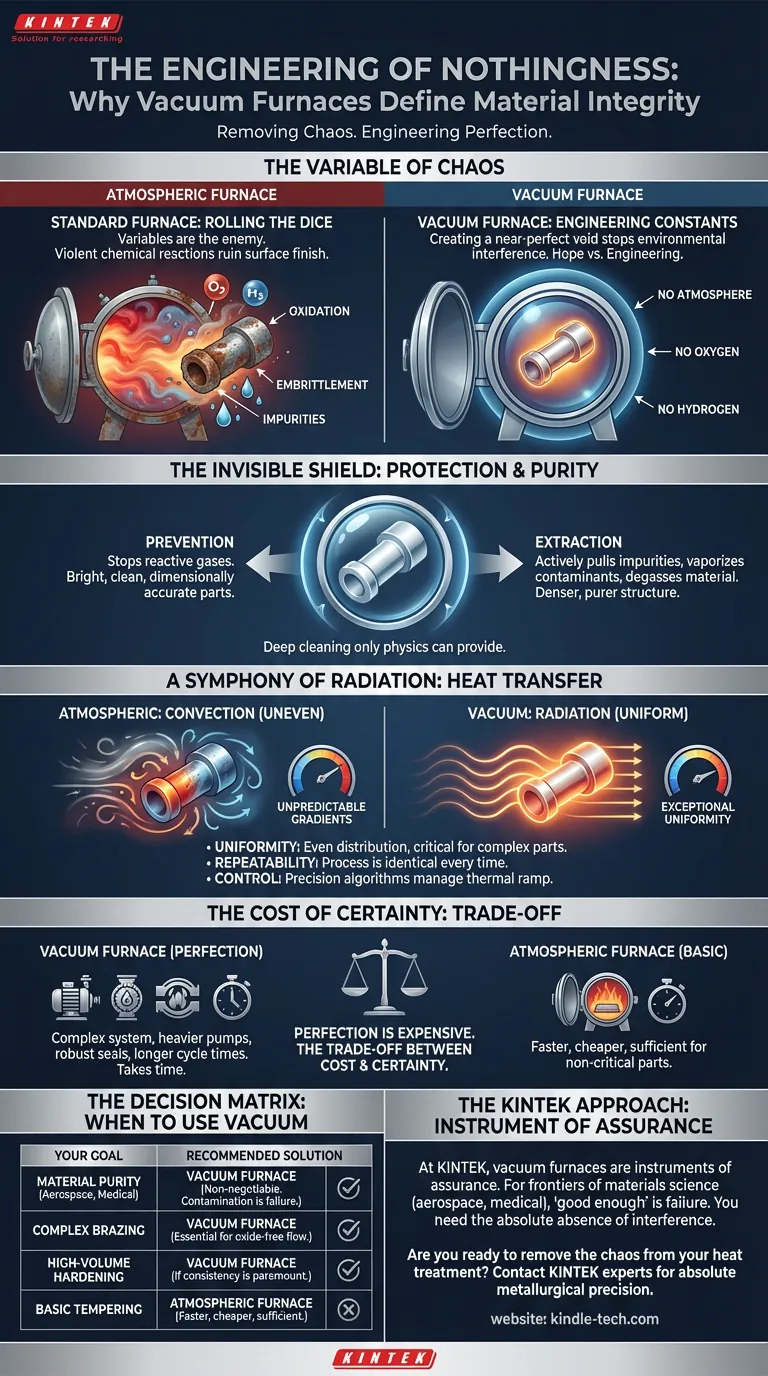

The Variable of Chaos

In engineering, variables are the enemy.

When you heat a metal component to 1,000°C, you are not just heating it. You are exposing it to a violent chemical reaction with its environment. In a standard atmospheric furnace, the air itself becomes an active participant. Oxygen attacks the surface. Hydrogen causes embrittlement. Moisture wreaks havoc.

You are rolling the dice with chemistry.

The vacuum furnace was not invented simply to heat things up. It was invented to remove the chaos.

By creating a near-perfect void, we stop treating the environment as a variable and start treating it as a constant. This is the difference between hoping for a good result and engineering a perfect one.

The Invisible Shield

The primary function of a vacuum furnace is not thermal; it is protective.

When you remove the atmosphere, you remove the oxygen. In a standard furnace, hot metal reacts instantly with oxygen to form scale—a rough, discolored oxide layer. This ruins the surface finish and alters the dimensions of the part.

In a vacuum, this reaction is physically impossible.

The Mechanism of Purity

The vacuum does more than just sit there. It is an active participant in purification.

- Prevention: It stops reactive gases from touching the surface. Parts emerge bright, clean, and dimensionally accurate.

- Extraction: The vacuum system actively pulls impurities out of the metal. It vaporizes contaminants and degasses the material, leading to a metallurgical structure that is denser and purer than the original stock.

It is a form of deep cleaning that only physics can provide.

A Symphony of Radiation

Heat transfer usually relies on convection—air moving around. But air moves unevenly. It creates hot spots, cold shadows, and unpredictable gradients.

In a vacuum, there is no air to move.

Heat must travel via radiation. This is the most direct and controllable form of energy transfer.

- Uniformity: The heat distribution is exceptionally even, critical for complex geometries where a 10°C difference can mean failure.

- Repeatability: Because the "air variable" is gone, the process is identical every single time.

- Control: Modern systems are governed by computer algorithms that manage the thermal ramp with the precision of a surgeon, ensuring the microstructure is transformed exactly as intended.

The Cost of Certainty

If vacuum furnaces are so superior, why isn't every furnace a vacuum furnace?

Because perfection is expensive.

This is the classic trade-off between cost and certainty.

A vacuum furnace is a complex system requiring heavy pumps, robust seals, and longer cycle times. You cannot simply open the door and toss a part in. You must pump down, heat, soak, and cool. It takes time.

The Decision Matrix

You do not use a vacuum furnace to bake a clay brick. You use it when the cost of failure exceeds the cost of the process.

| Your Goal | Recommended Solution |

|---|---|

| Material Purity (Aerospace, Medical) | Vacuum Furnace. Non-negotiable. Contamination is a failure mode. |

| Complex Brazing | Vacuum Furnace. Essential for oxide-free flow of filler metal. |

| High-Volume Hardening | Vacuum Furnace. If consistency and automation are paramount. |

| Basic Tempering | Atmospheric Furnace. Faster, cheaper, sufficient for non-critical parts. |

The KINTEK Approach

At KINTEK, we view the vacuum furnace not just as equipment, but as an instrument of assurance.

For laboratories working on the frontier of materials science—whether developing aerospace alloys or medical implants—the "good enough" results of atmospheric heating are actually failures. You need the void. You need the absolute absence of interference.

We specialize in high-performance vacuum furnaces designed for those who cannot afford variables. Our equipment provides the thermal uniformity and environmental control necessary to turn theoretical material properties into physical reality.

Are you ready to remove the chaos from your heat treatment?

Contact Our Experts to discuss how KINTEK can help you achieve absolute metallurgical precision.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

Related Articles

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum