Imagine spending months designing a critical alloy. You’ve balanced the elements perfectly for unparalleled strength and heat resistance. But when it emerges from the furnace, its surface is marred, and its internal structure is compromised.

The culprit wasn't a flaw in your design. It was the air itself.

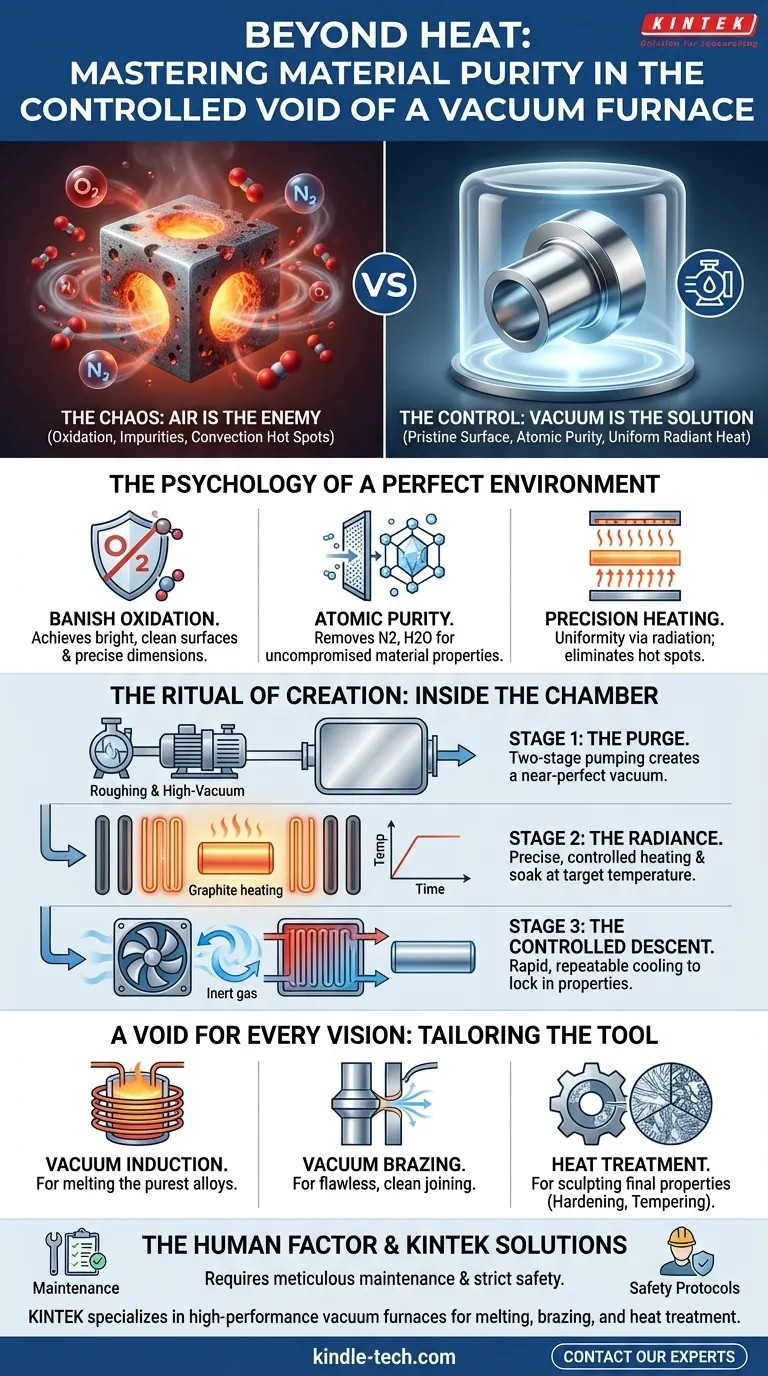

At high temperatures, the very atmosphere we depend on becomes a relentless adversary, introducing oxygen and other reactive gases that corrupt materials. The solution is not to apply more heat, but to create a fundamentally different environment. This is the world of the vacuum furnace—a world defined by what it removes.

The Psychology of a Perfect Environment

The core principle of a vacuum furnace is not about creating heat; it's about achieving absolute control. It's a psychological shift from battling variables to eliminating them entirely.

By removing the atmosphere, we remove the chaos of unpredictable chemical reactions. We create a pristine stage where heat can perform its work with surgical precision.

The Unseen Enemy: Oxidation

The most immediate and obvious enemy is oxygen. At high temperatures, it aggressively bonds with most metals, creating a brittle layer of oxide or scale.

In a vacuum, this enemy is banished. The result is a component with a bright, clean surface that retains its exact dimensions—a non-negotiable requirement for high-precision aerospace or medical parts.

Purity at the Atomic Level

The air isn't just oxygen. It's a mixture of nitrogen, water vapor, and other trace gases. For reactive metals like titanium or high-temperature superalloys, even the slightest contamination from these gases can degrade their mechanical properties.

A vacuum purges these impurities, ensuring the final material achieves its full, uncompromised potential.

The Physics of Precision Heating

Without air, heat can no longer transfer through convection. It moves purely through radiation from heating elements or is induced directly into the material.

This might seem like a small detail, but it's transformative. It allows for incredibly uniform heating across the entire workpiece, eliminating hot spots and ensuring a consistent internal microstructure.

The Ritual of Creation: Inside the Chamber

Every operation in a vacuum furnace follows a deliberate, automated sequence. It’s a ritual designed to move from the chaotic state of our atmosphere to a controlled, productive void.

Stage 1: The Purge

After the workpiece is loaded, the chamber is sealed. A series of pumps engage in a two-part process. First, a mechanical "roughing" pump removes the vast majority of the air. Then, a high-vacuum pump, like a diffusion or turbomolecular pump, takes over to achieve the near-perfect vacuum required.

Stage 2: The Radiance

With the environment secured, the heating elements—often made of graphite or molybdenum—begin to glow. The temperature climbs at a precisely controlled rate to the target setpoint, where it "soaks" for a specified duration. Every variable is monitored and managed by the furnace's control system.

Stage 3: The Controlled Descent

Cooling is just as critical as heating. For processes like hardening, the chamber is backfilled with a high-purity inert gas like argon or nitrogen. A powerful fan circulates this gas through a heat exchanger, pulling heat from the workpiece at a specific, repeatable rate to lock in the desired material properties.

A Void for Every Vision: Tailoring the Tool

Vacuum furnaces are not monolithic. They are specialized instruments, each designed to perfect a specific task. Understanding the design is key to choosing the right tool for your lab's objective.

For the Alchemist: Vacuum Induction Furnaces

When the goal is to melt and create the purest alloys, induction is the answer. An electromagnetic field heats the metal directly, without any contact from a heating element. This prevents any possible contamination, making it the definitive choice for specialty metallurgy.

For the Matchmaker: Vacuum Brazing Furnaces

Brazing joins two components into one. In a vacuum, this process is flawless. The absence of oxygen ensures surfaces are perfectly clean, allowing the brazing filler to flow smoothly and create a bond that is strong, clean, and free of the corrosive chemical fluxes required by other methods.

For the Sculptor: Heat Treatment Furnaces

For shaping the final properties of a finished part—hardening, tempering, or annealing—a standard resistance-heated vacuum furnace offers unparalleled control. It allows metallurgists to sculpt the microstructure of the material to achieve specific hardness, ductility, and strength.

The Human Factor in a Perfect System

The precision of a vacuum furnace demands discipline. It is a powerful tool that commands respect.

- Meticulous Maintenance: A vacuum system relies on perfect seals and clean pumps. A strict maintenance log and preventative checks are not optional; they are essential for repeatable success.

- Procedural Safety: Extreme temperatures and high pressures demand unwavering adherence to safety protocols. A moment of carelessness can lead to equipment damage or personal injury.

Achieving this level of control requires not just understanding the process but having laboratory equipment designed for precision and reliability. At KINTEK, we specialize in providing high-performance vacuum furnaces for melting, brazing, and heat treatment. Our solutions empower researchers and engineers to eliminate environmental variables and unlock the true potential of their materials.

To explore the right system for your application, Contact Our Experts .

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

Related Articles

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace