You’ve done everything right. The material is specified, the design is flawless, and the temperature profile is programmed to the letter. You open the furnace, expecting to see a perfect, high-performance component. Instead, you’re greeted with a dull, discolored surface. A quick test confirms your worst fear: the part is brittle, its properties are compromised, and weeks of work have just gone down the drain.

If this scenario feels painfully familiar, you are not alone.

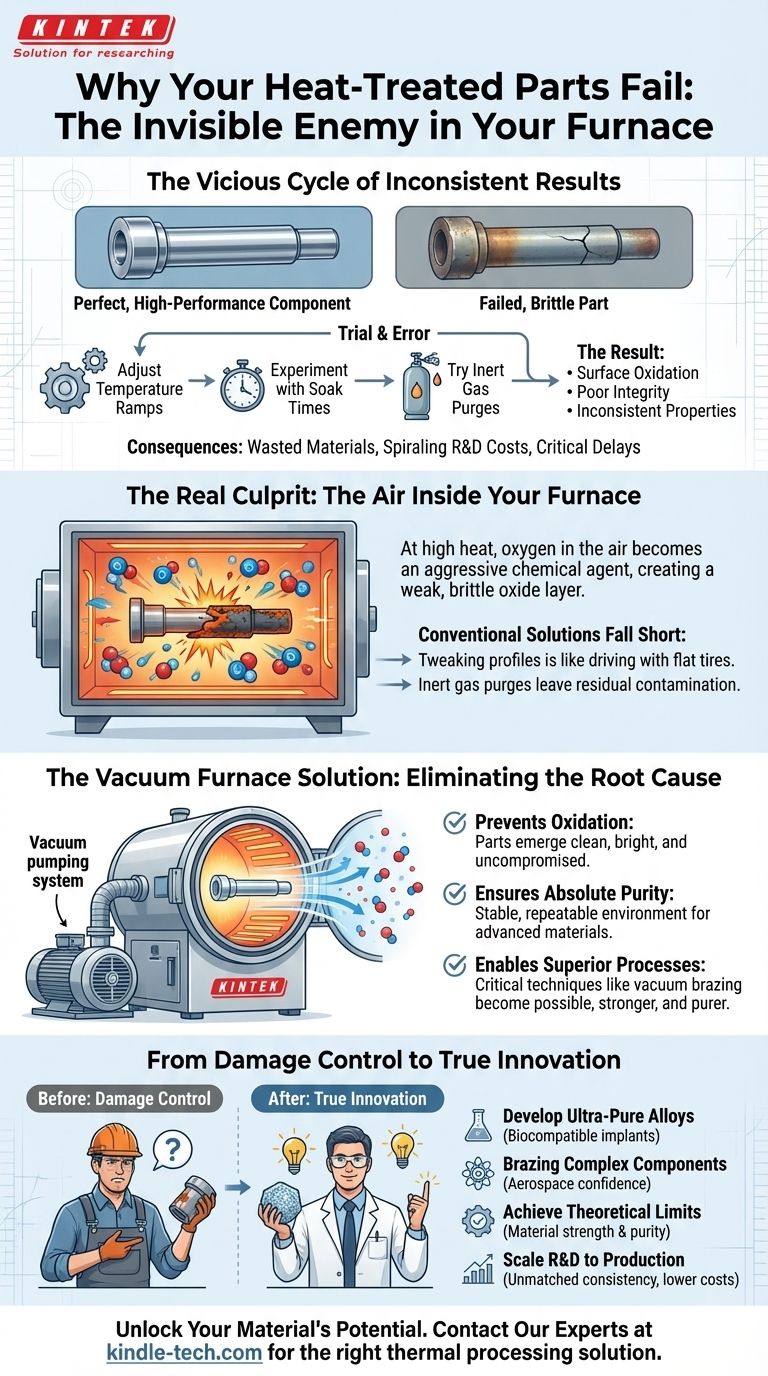

The Vicious Cycle of Inconsistent Results

For engineers and researchers working with advanced materials, achieving consistent quality during high-temperature processing can feel like a constant battle. When a part fails, the natural instinct is to blame the heating process itself.

So begins the cycle of trial and error:

- You meticulously adjust the temperature ramp rates.

- You experiment with longer soak times and different cooling profiles.

- You might even try purging the chamber with an inert gas, hoping to push out the "bad air."

Sometimes, you get a decent result. But the success is rarely repeatable. The next batch yields the same old problems: surface oxidation, poor structural integrity, and inconsistent material properties.

This isn't just a technical frustration; it has severe business consequences. Each failed batch translates to wasted materials, spiraling R&D costs, and critical project delays. In industries like aerospace, medical devices, or electronics, shipping a component that is merely "good enough" is not an option. It's a direct threat to product reliability and safety.

It's Not the Heat, It's the Atmosphere: The Real Culprit

Here is the frustrating truth: most of these efforts are destined for limited success because they are focused on the wrong problem. The root cause of your failure isn't the heat; it's the air inside your furnace.

At room temperature, the air around us is harmless. But at the high temperatures required for annealing, brazing, or sintering, ordinary air—specifically its oxygen content—becomes a highly aggressive chemical agent. It violently attacks the surface of your materials, creating a weak, brittle layer of oxides.

This is why your conventional solutions fall short:

- Tweaking temperature profiles is like perfecting your driving technique while your car has flat tires. You're optimizing the wrong variable.

- Inert gas purges are often incomplete, leaving residual oxygen and moisture that still cause contamination at critical temperatures.

You're trying to treat the symptoms—inconsistent results—without addressing the underlying disease: a reactive, uncontrolled atmosphere.

Fighting the Cause, Not the Symptom: How a Vacuum Creates Perfection

To get perfect, repeatable results every single time, you don't need a furnace that's simply better at heating. You need a tool that is designed to eliminate the root cause of the problem—the atmosphere itself.

This is the entire purpose of a vacuum furnace. It is not just a box that gets hot. Its primary, most critical function is to create a pristine, non-reactive environment by systematically removing the air before the heating process even begins.

A powerful pumping system creates a deep vacuum, reducing the pressure to a point where there are virtually no oxygen or water molecules left to contaminate your parts.

This is how a KINTEK vacuum furnace directly solves the core problem:

- It Prevents Oxidation: By removing the oxygen, oxidation becomes impossible. Your parts emerge from the furnace with clean, bright, and uncompromised surfaces, exactly as intended.

- It Ensures Absolute Purity: The vacuum environment is stable and perfectly repeatable. This is essential for sintering advanced materials or growing crystals for semiconductors, where even microscopic impurities can cause total failure.

- It Enables Superior Processes: Critical techniques like vacuum brazing become possible. Without any air, you can join complex assemblies using a filler metal that flows cleanly into the joint, creating a bond that is stronger, purer, and free of corrosive flux residue.

From Damage Control to True Innovation: What's Possible in a Perfect Environment?

When you no longer have to worry about the atmosphere sabotaging your work, a fundamental shift occurs. Your focus moves away from damage control and toward genuine innovation. The question is no longer, "How do I prevent this part from failing?" but rather, "What groundbreaking material can I create next?"

With the atmospheric variable completely eliminated, you unlock new potential:

- Develop ultra-pure alloys for medical implants that are biocompatible and reliable.

- Brazing complex, mission-critical aerospace components with absolute confidence in every joint.

- Achieve the theoretical limits of material strength and purity in your research.

- Scale from R&D to production with unmatched consistency, dramatically improving yield and reducing costs.

In short, you stop fighting with your equipment and start pioneering the future of your field.

Your project's success shouldn't be a game of chance. If you're tired of inconsistent results and ready to unlock the full potential of your materials, our team is here to help you design the right thermal processing solution. Let's discuss the unique challenges of your next project. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

Related Articles

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?