The Sinking Feeling of a Failed Batch

Imagine this: After weeks of careful preparation, you run a critical heat treatment cycle on a batch of expensive, custom-alloy components. You programmed the furnace to the precise temperature your process sheet demands. But when you open the door, your heart sinks.

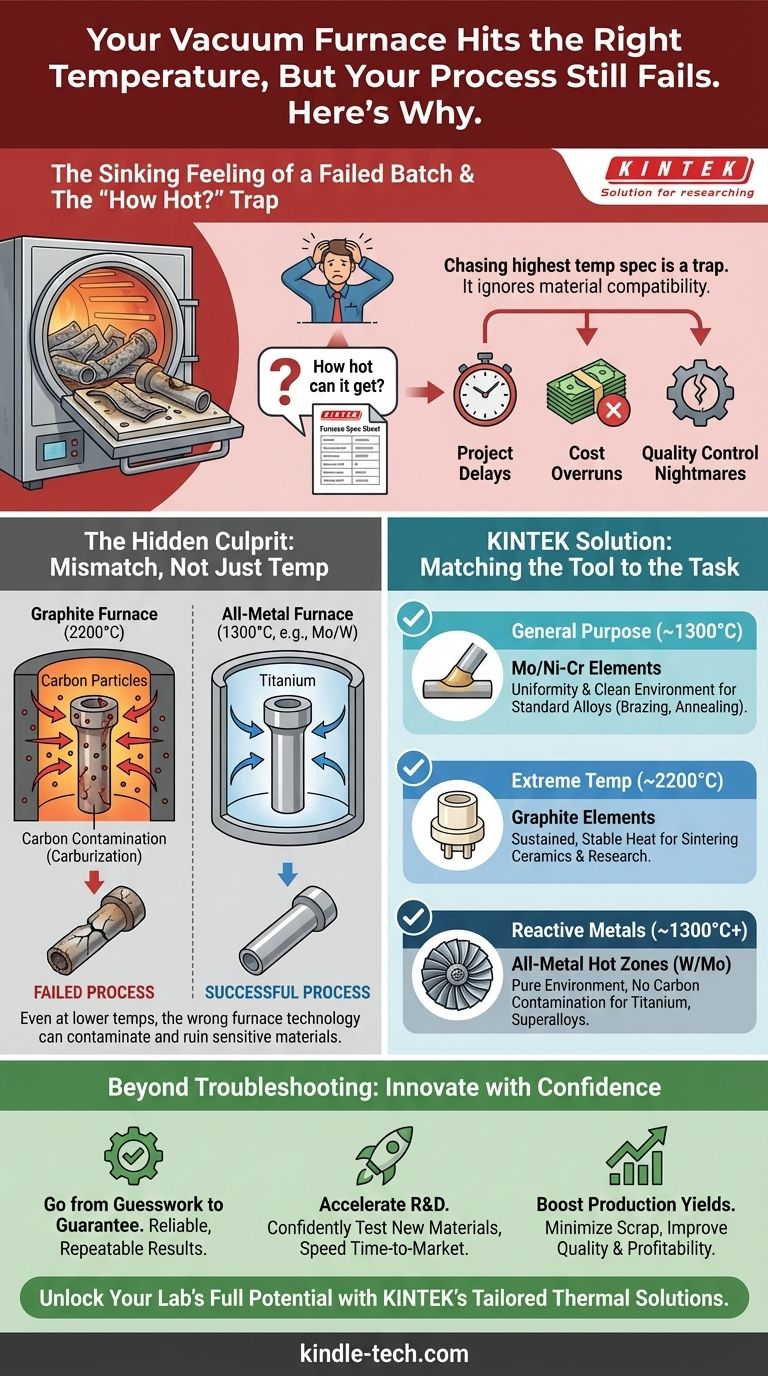

The parts are ruined. Perhaps they are brittle, warped, or discolored. Your project timeline is now in jeopardy, your budget has taken a hit, and you're back to square one with a frustrating question: "What went wrong?"

The Expensive Cycle of Trial-and-Error

This scenario is far too common in labs and production facilities. The immediate instinct is to troubleshoot the most obvious variable: temperature. Was it too low? Did it overshoot? You run the cycle again, tweaking parameters, burning through time, energy, and more valuable material, only to get another inconsistent result.

Frustrated, many teams conclude their equipment is the problem. They begin searching for a new furnace, and the search often narrows to a single question: "How hot can it get?"

This leads to comparing spec sheets, focusing on the maximum operating temperature as the key decision-making factor. The assumption is that a furnace with a higher temperature ceiling offers more capability and a wider margin for error.

But this seemingly logical approach is a trap. It often leads to purchasing the wrong equipment, which only perpetuates the cycle of failure. The business consequences are severe:

- Project Delays: R&D for new materials stalls, pushing back product launch dates.

- Cost Overruns: Budgets are consumed by repeated tests and scrapped high-value parts.

- Quality Control Nightmares: Inconsistent production batches lead to unreliable products and damage to your company's reputation.

The Hidden Culprit: Why 'Hotter' Isn't Better

Here is the turning point in our story. The problem isn't usually the temperature you can reach, but the way your furnace system achieves and contains that heat.

Chasing the highest temperature spec is a red herring. The real culprit behind most process failures is a fundamental mismatch between the furnace's core technology and the specific needs of your material.

It's Not Just a Number; It's a System

A vacuum furnace isn't just a hot box; it's an engineered system where every component matters. The maximum temperature is determined by the "weakest link" in that system, most notably the heating elements.

- Nickel-Chromium/Molybdenum Elements: These are the workhorses for general-purpose applications like brazing and annealing, reliably operating up to ~1300°C.

- Graphite Elements: To reach extreme temperatures of 2200°C or more for sintering ceramics or graphitization, graphite is the material of choice.

- Tungsten/Tantalum Elements: These refractory metals also achieve very high temperatures and are used when the presence of carbon is detrimental.

The Contamination Trap: When Your Furnace Fights Your Material

Here’s where the mismatch becomes critical. Let’s say you are processing a sensitive titanium alloy that requires a cycle at 1100°C. You might think a 2200°C graphite furnace gives you plenty of headroom.

You would be wrong.

Even at 1100°C, a graphite furnace's heating elements and insulation can release microscopic carbon particles into the vacuum. This carbon can infuse into your titanium parts, a process called carburization, making them brittle and useless. Your "better" high-temperature furnace actively sabotaged your process.

This is why the common "solution" of buying a hotter furnace fails. It ignores the underlying physics and chemistry of the system. You didn't need a hotter furnace; you needed the right kind of furnace.

The Solution: Matching the Tool to the Task

To break this cycle of failure, you must shift your thinking. The goal is not to find the furnace with the highest number, but to select a furnace where the heating technology, hot zone materials, and overall design are perfectly aligned with your application.

This is the core principle behind KINTEK's approach to laboratory equipment. We don't just sell furnaces; we provide precisely configured thermal solutions based on a deep understanding of material science. Our vacuum furnaces are designed as integrated systems that directly solve the root causes of process failure.

- For general heat treating, brazing, and annealing? Our resistance furnaces with molybdenum or nickel-chromium elements provide exceptional temperature uniformity and a clean environment, ensuring your standard alloys are processed perfectly up to 1300°C.

- For sintering advanced ceramics or materials research? Our high-temperature graphite furnaces are engineered to deliver sustained, stable heat up to 2200°C, providing the extreme environment you need.

- For processing reactive metals like titanium or superalloys? We provide furnaces with all-metal hot zones (using tungsten or molybdenum) that deliver the necessary heat without the risk of carbon contamination, guaranteeing the purity and integrity of your final product.

Our furnaces are the embodiment of the solution because they are designed with these critical distinctions in mind.

Beyond Troubleshooting: The Freedom to Innovate

When you finally have the right tool for the job—a furnace system that is an ally, not an adversary—everything changes. The energy once spent on troubleshooting is now freed up for innovation.

- Go from Guesswork to Guarantee: Achieve reliable, repeatable results, batch after batch, and establish standardized processes you can trust.

- Accelerate R&D: Confidently test the limits of new materials without second-guessing your equipment. This dramatically shortens your development cycle and speeds time-to-market.

- Boost Production Yields: Minimize scrap, improve product quality, and increase the profitability of your production lines.

Solving your furnace problem isn't just about getting a successful heat treatment. It’s about unlocking your lab's or your company's full potential to create, discover, and lead in your field.

Your material processing challenges are unique, and a one-size-fits-all solution is destined to fail. If you're tired of the cycle of trial-and-error and ready for predictable, successful outcomes, our team is here to help. We go beyond spec sheets to understand your specific process and material needs. Let's discuss your project and configure the perfect thermal system to achieve your goals. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Related Articles

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace