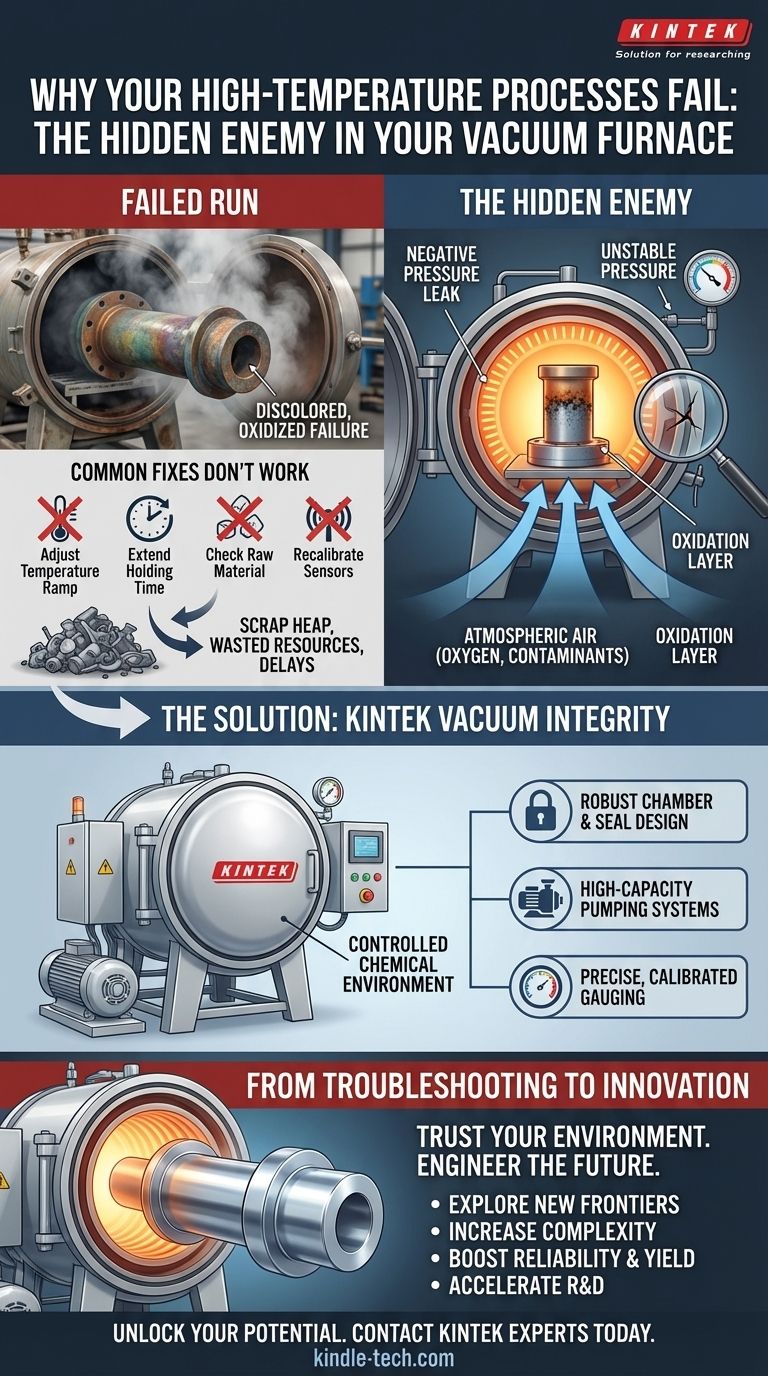

Imagine this: after hours, or even days, of a carefully planned heat treatment cycle, you open the vacuum furnace. Instead of the pristine, perfectly bonded component you expected, you find a discolored, oxidized failure. The part is ruined, the schedule is delayed, and you're left wondering: what went wrong this time?

This scenario is a costly and frustrating reality in many labs and manufacturing facilities. The component goes to the scrap heap, and the search for the cause begins.

Chasing Ghosts: Why Common Fixes Don't Work

When a high-temperature process like brazing, sintering, or annealing fails, the troubleshooting checklist is often predictable:

- "Was the temperature ramp rate too fast?"

- "Did the holding time need to be longer?"

- "Is this batch of raw material contaminated?"

- "Do the temperature sensors need recalibration?"

You might spend days tweaking process parameters, rerunning cycles, and analyzing materials, only to achieve another inconsistent result.

This isn't just an academic problem; it has severe business consequences. Each failed cycle wastes expensive raw materials, machine time, and significant energy. Project timelines slip, production yields drop, and you can't confidently guarantee the quality of your output. You're caught in a reactive loop, spending more time troubleshooting past failures than engineering future successes.

The Real Culprit: It's Not Your Process, It's Your Environment

Here is the fundamental truth that is often overlooked: a vacuum furnace is not just a hot box; it is a controlled chemical environment.

The entire purpose of pulling a vacuum is to remove reactive gases—primarily oxygen. At the extreme temperatures inside the furnace, even the smallest amount of oxygen can act as a potent contaminant, causing the very oxidation and discoloration you're trying to prevent. Your material becomes incredibly vulnerable, and its final properties depend entirely on the purity of its surroundings.

This reveals why your previous troubleshooting failed. You were adjusting the recipe while the oven itself was contaminated. The most common cause of this contamination is a negative pressure leak—a tiny, invisible breach in a seal, fitting, or weld that allows atmospheric air to be constantly sucked into the chamber.

Your vacuum pump works overtime, but it's fighting a losing battle against a steady trickle of incoming air. The gauge might show a pressure that seems "close enough," but it doesn't show the constant influx of contaminants that are actively ruining your product.

The Right Tool for the Job: Engineering for Vacuum Integrity

To solve this problem for good, you don't just need a furnace that gets hot. You need a system that can achieve and, more importantly, hold a pure, stable vacuum for the entire duration of your process. You need a tool built around the principle of pressure integrity.

This is where the focus shifts from the process to the equipment itself. A furnace designed for true vacuum integrity is fundamentally different. KINTEK's vacuum furnaces are engineered from the ground up to address this core challenge. They aren't just chambers that heat up; they are precision instruments for environmental control.

Our approach directly combats the root cause of failure:

- Robust Chamber & Seal Design: We use high-quality materials and superior construction techniques to prevent the micro-leaks that plague lesser systems.

- High-Capacity Pumping Systems: Our furnaces are equipped with pumps appropriately sized to not only reach the target vacuum quickly but also to overcome any minor outgassing from the material itself, maintaining pressure stability.

- Precise, Calibrated Gauging: You can trust the pressure readings. This allows you to know with certainty that your process environment is exactly what it should be, from the beginning of the cycle to the end.

A KINTEK furnace is not just a piece of hardware; it's the physical embodiment of a deep understanding of vacuum science, designed to eliminate the guesswork and deliver a stable environment you can rely on.

From Troubleshooting to Innovation: What's Possible Now?

When you can finally trust your vacuum environment, a remarkable shift happens. You stop troubleshooting the past and start engineering the future.

The energy your team once spent on forensic analysis of failed parts is now redirected toward innovation.

- Explore New Frontiers: You can confidently work with more sensitive, advanced materials that would have been impossible to process in an unstable environment.

- Increase Complexity: Longer, more intricate multi-stage thermal cycles can be run without fear of pressure drift ruining the result.

- Boost Reliability & Yield: In a production setting, you move from unpredictable yields to reliable, repeatable quality, increasing throughput and profitability.

- Accelerate R&D: By eliminating a major source of variability, your researchers can get to meaningful results faster, shortening the path from idea to breakthrough.

Ultimately, inconsistent vacuum pressure isn't just a technical glitch; it's a barrier to innovation and a drain on your resources. If you're ready to move past the cycle of failed runs and unlock the full potential of your high-temperature processes, our team is here to help you design a system that delivers predictable, high-quality results every time. Let's discuss the unique demands of your project; Contact Our Experts to start the conversation.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Related Articles

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity