Introduction to Vitamin E and Its Market Impact

Market Reaction to BASF Incident

On August 7, BASF, a leading global chemical company, announced the temporary suspension of production for several key products, including vitamin A (VA), vitamin E (VE), and carotenoids, due to a significant fire at its plant in Germany. This unexpected disruption in the supply chain immediately sent ripples through the market, particularly affecting domestic suppliers in China. Companies such as Zhejiang Pharmaceutical Company, Xinhecheng Pharmaceutical, Crown shares, and Beida Pharmaceuticals saw a notable surge in their stock prices.

The immediate market reaction was characterized by a sharp increase in the prices of these vitamins. This price hike was driven by the sudden scarcity of supply, which led to heightened demand and aggressive bidding from buyers seeking to secure their inventories. The incident highlighted the vulnerability of the global supply chain for critical nutrients like vitamin E, which is not only essential for human health but also a key ingredient in various pharmaceutical and dietary supplement products.

The BASF incident underscored the importance of supply chain resilience and the potential for rapid market shifts in response to unforeseen events. For domestic suppliers, this presented both a challenge and an opportunity. While they had to navigate the complexities of meeting sudden increased demand, they also benefited from the price escalation, which bolstered their revenue and market position.

In the broader context, the BASF fire incident serves as a case study in how global supply chain disruptions can impact not just individual companies, but entire industries. It also raises questions about the need for diversification of supply sources and enhanced contingency planning to mitigate future risks.

Role and Sources of Vitamin E

Vitamin E plays a crucial role in various biological processes, particularly in the promotion of sex hormone secretion and the enhancement of fertility. Additionally, it acts as a potent antioxidant, inhibiting lipid peroxide reactions within the eye lens, thereby protecting ocular health. The sources of vitamin E can be broadly categorized into natural and synthetic forms, each with distinct characteristics and applications.

Natural vitamin E, derived from plant-based oils such as soybean and sunflower oils, exhibits higher biological activity compared to its synthetic counterpart. This heightened activity is attributed to its more natural structure, which the human body can more readily absorb and utilize. Moreover, natural vitamin E is considered safer due to its lower risk of adverse effects, making it the preferred choice for dietary supplements and health-promoting products.

On the other hand, synthetic vitamin E, produced through chemical processes, offers a cost-effective alternative but with reduced bioavailability. Despite its lower biological activity, synthetic vitamin E remains a significant source in the food and pharmaceutical industries, particularly where cost considerations take precedence over bioavailability.

The choice between natural and synthetic vitamin E depends on the specific application and the desired outcomes. For instance, in the formulation of dietary supplements aimed at maximizing health benefits, natural vitamin E is typically favored. Conversely, in industries where cost efficiency is critical, synthetic vitamin E may be the more practical option.

In summary, the dual sources of vitamin E—natural and synthetic—provide flexibility in meeting diverse market demands, ensuring that both health-conscious consumers and cost-sensitive industries can access this essential nutrient.

Methods of Purifying Natural Vitamin E

Molecular Distillation

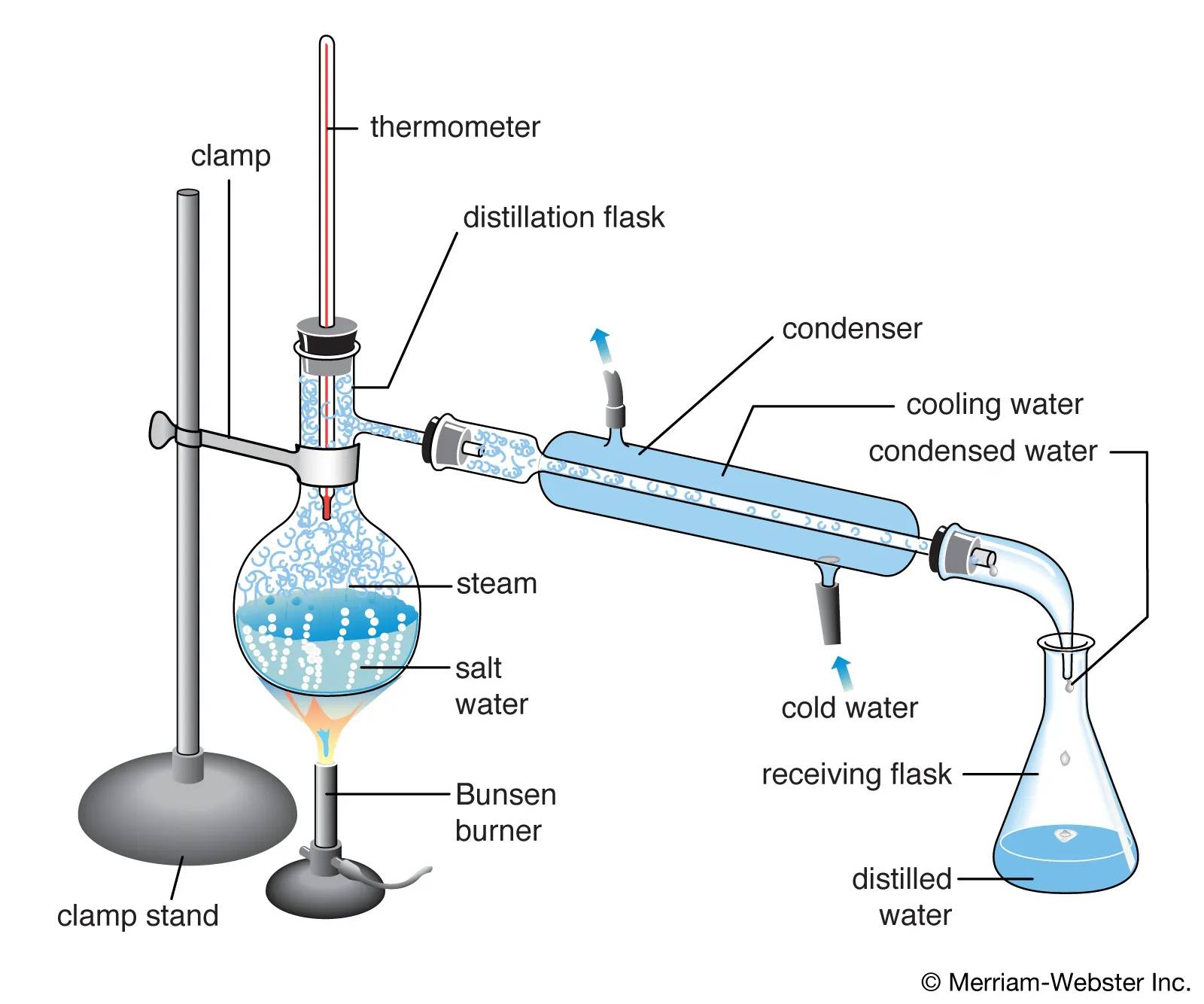

Molecular distillation is a specialized technique used for the separation and purification of natural vitamin E, owing to its high efficiency and minimal risk of introducing impurities. This method operates under extremely low vacuum pressures, typically below 0.01 torr (1.3 Pa), which places it in the realm of high vacuum distillation. At these pressures, the mean free path of molecules becomes comparable to the dimensions of the distillation equipment, transitioning the process into the free molecular flow regime.

In molecular distillation, the gaseous phase exerts negligible pressure on the substance being evaporated, meaning the rate of evaporation is no longer dependent on external pressure. This characteristic is crucial for heat-sensitive materials like natural vitamin E, as it allows for short heating times and low temperatures, preserving the integrity and biological activity of the vitamin. The process typically involves a short path between the hot and cold surfaces, often achieved by positioning a hot plate coated with the feed material adjacent to a cold plate, ensuring direct line-of-sight molecular movement.

This method is not only simple but also highly effective in concentrating natural products, including complex and thermally sensitive molecules such as vitamins and polyunsaturated fatty acids. The short exposure of the distillate liquid to high temperatures, combined with the high vacuum environment (around 10−4 mmHg) and the minimal distance between the evaporator and condenser (typically around 2 cm), ensures that the final product maintains its purity and potency.

Molecular distillation is extensively used in industrial settings for the purification of oils, further highlighting its versatility and effectiveness in handling a variety of substances. Its unique operational parameters make it an indispensable tool in the field of natural vitamin E extraction and purification, offering a balance of precision and efficiency that is hard to match with other methods.

Vacuum Distillation

Vacuum distillation is a cost-effective method for separating compounds, particularly those with high boiling points, by operating under reduced pressure. This technique allows for distillation at lower temperatures, thereby minimizing the risk of thermal degradation, which is crucial for heat-sensitive substances like natural vitamin E. However, its effectiveness is limited when it comes to separating compounds with similar boiling points, such as those found in the complex mixtures of vitamin E.

Under vacuum conditions, the boiling points of compounds are significantly reduced, enabling distillation without the need for high temperatures. For instance, water boils at 212°F (100°C) at sea level, but in Denver, CO, it boils at 203°F (95°C) due to the lower atmospheric pressure. This principle is applied in vacuum distillation to facilitate the separation of compounds that would otherwise decompose at their normal boiling temperatures.

Despite its advantages, vacuum distillation is not ideal for separating substances with closely related boiling points, as the temperature differences required for effective separation are not achieved. This limitation is particularly relevant in the purification of natural vitamin E, where the presence of compounds with similar boiling points complicates the separation process. Therefore, while vacuum distillation is a valuable tool in the arsenal of purification techniques, it must be complemented with other methods to achieve the desired purity and efficiency in the extraction of natural vitamin E.

Supercritical CO2 Technology

Supercritical CO2 technology stands out in the realm of extraction methods due to its unique ability to manipulate both temperature and pressure to yield precise extracts. This technology leverages the properties of carbon dioxide when it is pressurized to a supercritical state, allowing it to permeate through cannabis material with high solubility. The process involves passing a CO2 stream through a chamber containing the cannabis material, which dissolves the active compounds. Post-extraction, reducing the pressure allows for the easy isolation of the distillate, as the CO2 evaporates, leaving behind a solvent-free cannabis extract.

One of the key advantages of supercritical CO2 technology is its ability to preserve the complete terpene profile of the cannabis, which is crucial for maintaining the plant's therapeutic and aromatic properties. This is achieved through sophisticated extraction apparatus that can incorporate fractionation, enabling the tuning of the process to isolate specific components. Additionally, the integration of refrigerated chillers and recirculating heaters facilitates the recycling of CO2 by condensing the gas back to a liquid state and assisting in the removal of CO2 from the extract, respectively.

However, despite its numerous benefits, supercritical CO2 technology is not without its challenges. The initial setup costs are notably high, which can be a significant barrier for entry, especially for smaller operations. Moreover, the single recovery rates tend to be lower compared to other methods, necessitating more complex and costly processes to achieve the desired yields. These factors highlight the need for ongoing research and development to optimize the technology and make it more accessible and cost-effective for widespread use in the cannabis industry.

Application of Molecular Distillation in Vitamin E Purification

Raw Material Pretreatment

The process of enriching natural vitamin E content from soybean oil deodorized distillate involves a meticulous pretreatment phase, which encompasses both esterification and saponification. This initial step is crucial as it not only prepares the raw material for subsequent purification but also significantly enhances the concentration of natural vitamin E within the distillate.

During esterification, the fatty acids in the distillate are converted into esters, a process that often involves the use of an acid catalyst. This transformation facilitates the separation of vitamin E from other compounds, thereby increasing its availability for extraction. Following esterification, saponification is employed to convert the esters back into their original fatty acids and glycerol, a reaction typically catalyzed by a strong base. This step not only purifies the vitamin E but also ensures that it is in a form that is more amenable to further processing.

The combination of these two processes results in a distillate that is enriched with natural vitamin E, setting the stage for the more advanced purification techniques such as short path vacuum distillation. This preliminary treatment is pivotal in the overall efficiency and effectiveness of the vitamin E extraction process, ultimately leading to a higher yield of the valuable nutrient.

Natural Vitamin E Extraction

After undergoing a series of pretreatment processes, including esterification and saponification, the enriched soybean oil deodorized distillate is subjected to molecular distillation. This advanced technique is pivotal in the extraction of natural vitamin E, leveraging its ability to operate at low temperatures and short heating times. These conditions are particularly advantageous for preserving the integrity of heat-sensitive materials, such as natural vitamin E, which can degrade under high temperatures.

The molecular distillation process is meticulously controlled to ensure optimal extraction conditions. These conditions are designed to maximize the concentration of natural vitamin E in the final product, achieving levels of up to 40%. This high concentration is a testament to the efficacy of molecular distillation in separating natural vitamin E from its complex matrix, without the introduction of impurities.

In comparison to other methods like vacuum distillation and supercritical CO2 technology, molecular distillation stands out for its simplicity and efficiency. While vacuum distillation is cost-effective, it struggles with separating substances that have boiling points similar to vitamin E. On the other hand, supercritical CO2 technology, though offering high permeability and solubility, is hindered by high initial costs and low single recovery rates.

Thus, molecular distillation emerges as the preferred method for the purification of natural vitamin E, balancing efficiency, cost-effectiveness, and product purity. This method not only ensures a high yield of natural vitamin E but also maintains its biological activity and safety, making it an ideal choice for the production of high-quality vitamin E supplements.

Natural Vitamin E Refining

The process of refining natural vitamin E to achieve high purity involves two primary methods: chromatographic adsorption and ion exchange resin techniques. Each method offers distinct advantages and limitations, contributing to the overall efficiency and quality of the final product.

Chromatographic Adsorption: This method is renowned for its precision and ability to separate complex mixtures. By utilizing various adsorbents, it can effectively isolate natural vitamin E from other compounds, ensuring a high level of purity. However, this technique requires specialized equipment and can be costly in terms of both materials and operation.

Ion Exchange Resin: This method is characterized by its efficiency and cost-effectiveness. Ion exchange resins are particularly adept at capturing and retaining specific ions, making them ideal for purifying natural vitamin E. Despite its advantages, this method may face limitations in handling large volumes and may require frequent regeneration of the resins.

Both methods play crucial roles in the refining process, each contributing to the final product's quality and purity. The choice of method often depends on the specific requirements and constraints of the production process, balancing efficiency, cost, and purity.