Water Vapor Transport in Lyophilization

Sublimation and Vacuum Conditions

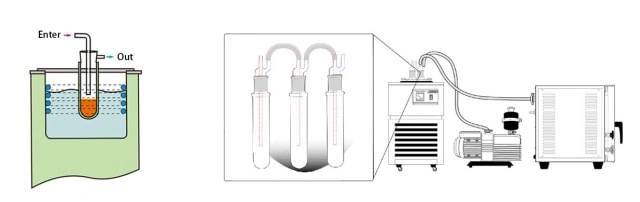

During the process of sublimation drying, ice transitions directly from a solid to a gaseous state, bypassing the liquid phase, under the combined influence of vacuum and shelf heating. This transformation yields water vapor, which, under the typical lyophilization pressure range, cannot be effectively removed by conventional vacuum pumps. The inability of these pumps to manage the generated water vapor necessitates the incorporation of a condenser, commonly referred to as a cold trap.

The cold trap serves as a critical component in the lyophilization setup, designed to capture and condense the water vapor produced during sublimation. Without this specialized equipment, the vacuum system would be overwhelmed, leading to inefficiencies and potential process failures. The cold trap's role is not merely passive; it actively contributes to maintaining the necessary vacuum conditions, ensuring that the sublimation process can proceed smoothly and efficiently.

In essence, the cold trap acts as a buffer, preventing the build-up of water vapor that could otherwise compromise the vacuum integrity and disrupt the delicate balance required for successful lyophilization. Its presence is indispensable, highlighting the intricate interplay between vacuum conditions and the design of auxiliary equipment in achieving optimal drying outcomes.

Resistances in Water Vapor Transport

Several factors impede the efficient transport of water vapor during the lyophilization process, each contributing differently to the overall resistance. These include dry product resistance, glue plug resistance, drying oven-cold trap piping resistance, resistance to condensation in the cold trap, and refrigeration system resistance. Among these, dry product resistance stands out as the most significant, constituting a substantial 80-90% of the total mass transfer resistance.

Dry product resistance is primarily due to the porous structure of the dried product, which creates a significant barrier for water vapor to escape. This resistance is influenced by the material's physical properties, such as porosity and surface area, which can vary widely depending on the formulation and drying conditions.

Glue plug resistance, on the other hand, arises from the adhesive used to seal the product vials. This adhesive can form a semi-permeable barrier that impedes water vapor flow, especially if not applied uniformly or if it interacts chemically with the product.

The piping connecting the drying oven to the cold trap also presents a resistance. This is due to the length and diameter of the piping, as well as any bends or obstructions that can slow down the flow of water vapor. Proper design and maintenance of this piping are crucial to minimizing resistance and ensuring efficient vapor transport.

Within the cold trap itself, resistance to condensation is a critical factor. The cold trap's ability to condense water vapor efficiently depends on its temperature and surface area. If the cold trap is not sufficiently cooled or if its surface area is inadequate, it can become a bottleneck, significantly increasing the overall resistance.

Lastly, the refrigeration system's resistance is tied to its ability to maintain the necessary low temperatures in the cold trap. Inefficiencies in the refrigeration system, such as inadequate cooling capacity or poor insulation, can lead to higher resistance and affect the overall performance of the lyophilization process.

In summary, while various resistances impact water vapor transport, dry product resistance is by far the most dominant, highlighting the importance of optimizing product formulation and drying conditions to enhance the overall efficiency of the lyophilization process.

Impact of Cold Trap Design on Lyophilization

Consequences of Uncontrolled Vacuum

Uncontrolled vacuum within the drying oven can precipitate a cascade of detrimental effects, jeopardizing the entire lyophilization process. At the onset, the rapid escalation of product temperature can occur, driven by the absence of the stabilizing pressure that a controlled vacuum provides. This temperature spike can be particularly hazardous for sensitive materials, potentially leading to product collapse or degradation. The structural integrity of the product is at risk, as the uncontrolled environment fails to support the delicate balance necessary for successful drying.

Moreover, the vacuum pump's longevity is significantly compromised when the cold trap is overwhelmed. The cold trap, designed to condense water vapor and protect the vacuum pump, can become overloaded in an uncontrolled vacuum scenario. This overload results in the pump's continuous operation under excessive strain, leading to accelerated wear and tear. Consequently, the service life of the vacuum pump is curtailed, necessitating premature maintenance or replacement and increasing operational costs.

In summary, the consequences of an uncontrolled vacuum extend beyond immediate process failure to encompass long-term equipment durability and product quality. Ensuring precise control over vacuum conditions is thus imperative for maintaining the integrity of both the lyophilization process and the equipment involved.

Requirements for Ideal Cold Trap Design

An ideal cold trap should be meticulously designed to handle the complexities of water vapor transport efficiently. The primary requirement is its ability to facilitate large water vapor transfer, ensuring that the vapor generated during the lyophilization process is effectively captured and condensed. This capability is crucial for maintaining the vacuum conditions necessary for sublimation drying.

The cooling coil surface area is another critical factor. A larger surface area allows for more efficient heat exchange, enhancing the trap's ability to condense water vapor. This design aspect is essential for maintaining a small temperature difference between the coil's inlet and outlet, which ensures consistent and efficient cooling throughout the process.

Proper connection to the vacuum pump is also paramount. The cold trap must interface seamlessly with other labware, including vacuum flanges and various types of joints, to prevent gas accumulation. This seamless integration ensures that the vacuum pump operates optimally, extending its service life and preventing process failures.

Additionally, the cold trap should be compatible with different types of coolants, such as dry ice or liquid nitrogen, to accommodate varying operational temperature ranges. This flexibility allows the trap to handle a broader spectrum of chemicals, enhancing its versatility in the laboratory setting.

| Design Aspect | Importance |

|---|---|

| Large Water Vapor Transfer | Ensures efficient capture and condensation of water vapor during sublimation. |

| Sufficient Cooling Coil Area | Enhances heat exchange, maintaining a small temperature difference. |

| Proper Vacuum Pump Connection | Prevents gas accumulation, ensuring optimal pump performance. |

| Coolant Compatibility | Allows for flexible operation across different temperature ranges. |

In summary, an ideal cold trap design must balance these critical elements to support the intricate demands of the lyophilization process, ultimately enhancing product quality and process efficiency.

Related Products

- Vacuum Cold Trap Direct Cold Trap Chiller

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use