Introduction to Sputtering Targets

Definition and Types

Planar targets and rotary targets represent the two primary categories of sputtering targets employed in material research. These targets serve as the foundation for various deposition processes, each contributing distinct structural and functional attributes to the research outcomes.

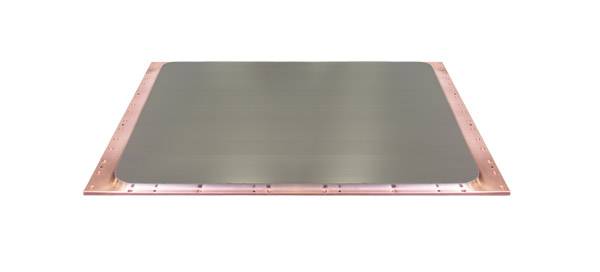

Planar targets, often referred to as flat targets, are typically composed of a single, homogeneous material. They are statically positioned within the target chamber, where they undergo processes such as sputtering deposition and ion beam bombardment. The simplicity of their design allows for straightforward integration into existing systems, facilitating both ease of use and a high degree of process control.

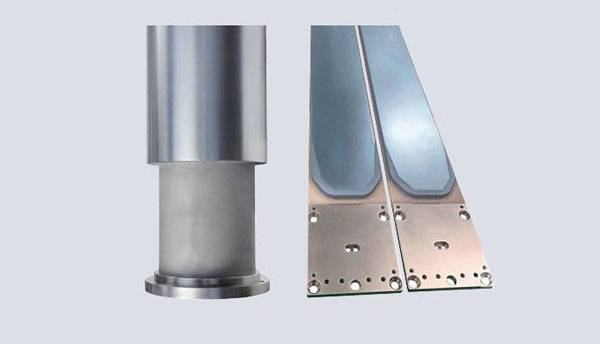

On the other hand, rotary targets are engineered to rotate during the sputtering process. This rotational motion ensures a more uniform distribution of material across the target surface, mitigating the localized consumption patterns seen in planar targets. The dynamic nature of rotary targets not only enhances material utilization but also introduces a level of complexity that can be leveraged for more intricate experimental setups.

Both types of targets, while fundamentally different in their operational mechanisms, share the common goal of enabling precise material deposition. Their unique characteristics make them suitable for a wide array of applications, from fundamental research to industrial-scale production, each catering to specific needs and experimental constraints.

Characteristics of Flat Targets

Structure and Usage

Flat targets, meticulously crafted from pure materials, are strategically positioned within a controlled environment known as the target chamber. These targets serve as the foundational components in experimental setups designed for sputtering deposition and ion beam bombardment. The simplicity of their structure belies their critical role in these processes, where they facilitate the precise layering of materials onto substrates.

In sputtering deposition, flat targets are subjected to a bombardment of ions, causing atoms from the target's surface to be ejected and subsequently deposited onto a nearby substrate. This method is particularly valued for its ability to produce high-quality, uniform films with minimal defects. Similarly, in ion beam bombardment experiments, the flat targets act as the primary surface upon which ions are directed, allowing for the study of material interactions at the atomic level.

The utilization of flat targets in these experiments is not merely a matter of convenience but is driven by the need for precise control and reproducibility. Each target is designed to maintain its integrity under the intense conditions of the experiment, ensuring that the results are both accurate and consistent. This meticulous attention to detail underscores the importance of flat targets in advancing our understanding of material science and in the development of new technologies.

Advantages

Flat targets offer a range of benefits that make them a preferred choice in various material research applications. One of the primary advantages is their simplicity and versatility. These targets are straightforward in design, making them easy to install and operate within a target chamber. This simplicity reduces the complexity of the setup, which can lead to fewer operational issues and lower maintenance requirements.

Moreover, flat targets contribute significantly to the uniformity and repeatability of film layers. The consistent nature of flat targets ensures that the material is distributed evenly across the surface, which is crucial for achieving high-quality film layers. This uniformity is particularly important in applications where precise control over the film's properties is necessary, such as in semiconductor manufacturing and thin-film coatings.

In addition to their structural simplicity, flat targets are highly versatile. They can be made from a variety of materials, including metals, alloys, and compounds, allowing researchers to explore different material properties and applications. This versatility makes flat targets a flexible option for a wide range of experiments, from sputtering deposition to ion beam bombardment.

Despite their advantages, it is important to note that flat targets also have limitations, such as lower target utilization rates due to the formation of striped craters as the material is consumed. However, their simplicity and the benefits they offer in terms of film uniformity and repeatability make them a valuable tool in material research.

Disadvantages

The primary drawback of flat sputtering targets is their low target utilization, which typically hovers around 20%. This inefficiency is largely attributed to the formation of striped craters as the material is gradually consumed. These craters, which appear as the target is bombarded with ions, lead to uneven erosion patterns, significantly reducing the effective surface area available for sputtering.

To put this into perspective, consider that for every 100 units of material, only 20 units are effectively utilized, while the remaining 80 units are either wasted or become less effective due to the craters. This not only increases the cost of production but also limits the longevity of the target, necessitating frequent replacements.

| Issue | Impact |

|---|---|

| Striped Craters | Reduces effective surface area, leading to low target utilization |

| Inefficient Material Use | Only 20% of material is effectively used, increasing production costs |

| Frequent Replacements | Shortens the lifespan of the target, requiring more frequent maintenance |

The craters, which form along the edges of the bombarded areas, create a non-uniform surface that disrupts the consistency of the sputtered films. This non-uniformity can result in films with varying thicknesses and properties, which can be detrimental to the quality and performance of the final product.

Characteristics of Rotary Targets

Structure and Usage

Rotary targets are designed with a unique rotating mechanism that allows them to operate at varying speeds and in multiple directions. This rotational capability is crucial for achieving a more uniform distribution of material across the target surface. Unlike flat targets, which are static and prone to uneven material consumption, rotary targets mitigate this issue by continuously exposing fresh sections of the target to the sputtering process.

The rotation of the target can be precisely controlled, enabling researchers to optimize the material distribution based on the specific requirements of their experiments. This control extends to the direction of rotation, which can be set to either clockwise or counterclockwise, further enhancing the flexibility and effectiveness of the sputtering process.

Moreover, the dynamic nature of rotary targets ensures that the material is evenly distributed, reducing the likelihood of localized depletion and extending the overall lifespan of the target. This even distribution is particularly beneficial in applications where high uniformity of the deposited film is essential, such as in the production of high-quality optical coatings or semiconductor materials.

In summary, the rotational functionality of rotary targets not only enhances the efficiency of material usage but also improves the overall quality and consistency of the sputtered films, making them a superior choice for many material research applications.

Advantages

Rotary targets significantly enhance target utilization and compactness, effectively tackling the low utilization issue prevalent in flat targets. Unlike flat targets, which often suffer from low utilization rates, typically around 20%, rotary targets maximize the use of the target material. This is achieved through their unique rotating mechanism, which ensures a more even distribution of material across the target surface.

The rotational motion of rotary targets not only increases material efficiency but also contributes to a more compact design. This compactness is particularly advantageous in laboratory settings where space is often limited. By minimizing wasted material and optimizing space usage, rotary targets offer a more sustainable and practical solution for material research.

Moreover, the higher target utilization in rotary targets directly addresses the common problem of striped crater formation observed in flat targets. This issue, caused by uneven material consumption, is effectively mitigated in rotary targets, leading to a more consistent and reliable sputtering process.

In summary, rotary targets bring substantial improvements in target utilization and compactness, making them a superior choice for researchers aiming to enhance efficiency and reduce waste in their sputtering experiments.

Disadvantages

The generation of numerous glow rings on the target surface during the sputtering process can significantly compromise the uniformity of the film when coating large areas. This phenomenon arises because the distribution of material is not evenly spread across the target surface, leading to localized areas of higher and lower material concentration. As a result, the film deposited on the substrate may exhibit variations in thickness and composition, which can adversely affect the performance and reliability of the final product.

Moreover, the uneven material distribution can also contribute to the formation of defects such as pinholes and cracks in the film, further reducing its overall quality. This issue is particularly pronounced in applications where high precision and consistency are critical, such as in the manufacturing of optical coatings or semiconductor devices.

To illustrate the impact of glow rings on film uniformity, consider the following table:

| Glow Ring Characteristics | Impact on Film Uniformity |

|---|---|

| High density of glow rings | Increased film thickness variation |

| Uneven glow ring distribution | Formation of pinholes and cracks |

| Large area coverage | Reduced overall film quality |

In summary, while rotary targets offer enhanced target utilization and compactness, the presence of glow rings remains a significant drawback that can undermine the uniformity and quality of the film during large area coating processes.

Conclusion

Choosing the Right Target

When selecting between planar and rotary sputtering targets, the decision should be guided by a comprehensive understanding of both the specific project requirements and the desired product outcomes. Each type of target offers distinct advantages and disadvantages that can significantly influence the quality and efficiency of the sputtering process.

For instance, planar targets are renowned for their simplicity and versatility, which contribute to the uniformity and repeatability of the film layers they produce. However, their primary drawback lies in their low target utilization, often around 20%, due to the formation of striped craters as the material is consumed. This issue can lead to inefficiencies and increased costs over time.

On the other hand, rotary targets provide a more even distribution of material due to their ability to rotate at various speeds and directions. This feature not only enhances target utilization but also addresses the compactness issues associated with planar targets. Despite these advantages, rotary targets can suffer from poor film surface uniformity during large-area coating, primarily due to the generation of multiple glow rings on the target surface.

In summary, the optimal choice between planar and rotary targets hinges on a detailed analysis of the project's specific needs, including considerations of film uniformity, target utilization, and overall process efficiency.