Introduction: Rotary Evaporator for Chemistry and Cooking

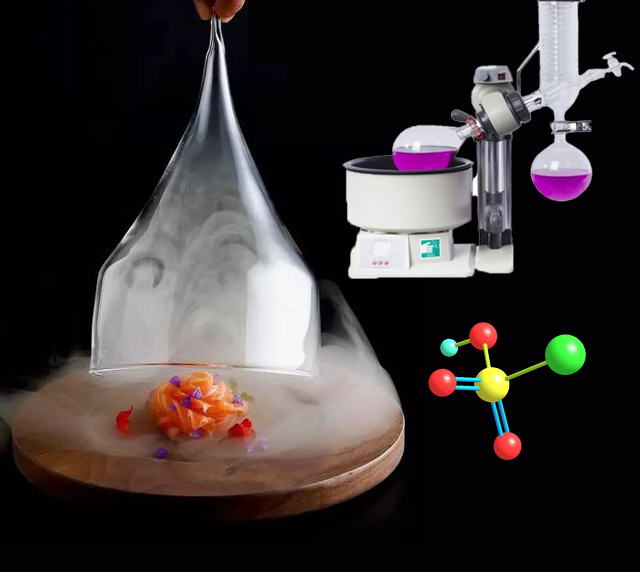

A rotary vacuum evaporator is a laboratory equipment that uses a rotating flask to remove solvents from a sample. It works by creating a vacuum in the system, which lowers the boiling point of the solvent and allows it to evaporate at lower temperatures. This makes it an essential tool for chemists who need to separate compounds from a mixture. However, the rotary evaporator is not limited to just the laboratory. It has found its way into the kitchen and is now being used by chefs to create unique and flavorful dishes. In this blog post, we will explore the versatility of this equipment and how it is being used in both chemistry and cooking.

Table of Contents

- Introduction: Rotary Evaporator for Chemistry and Cooking

- What is a Rotary Vacuum Evaporator?

- How does a rotary evaporator work?

- Benefits of using a rotary vacuum evaporator

- Usage of Rotary Evaporator in Cooking

- Rotary Evaporator Cooking Examples

- Rotary Evaporator in Coffee-Making

- Conclusion: The Versatility of Rotary Vacuum Evaporator

What is a Rotary Vacuum Evaporator?

A rotary vacuum evaporator, also known as a rotovap, is a laboratory equipment that is widely used in various industries, including chemistry and cooking. The device is designed to remove solvents from a sample mixture, leaving behind a concentrated substance for further analysis. The operation of the rotary vacuum evaporator is based on the principle of lowering the boiling point of the solvent by creating a vacuum, which allows the solvent to evaporate at a lower temperature than it would under normal conditions.

Components of a Rotary Vacuum Evaporator

The main components of a rotary vacuum evaporator include a heating bath, a rotating flask, a condenser, and a vacuum pump. The heating bath provides the energy required to vaporize the solvent, while the rotating flask ensures that the solvent is evenly distributed and exposed to the vacuum. The condenser collects the vaporized solvent, which can be reused or disposed of safely.

Working Principle of a Rotary Vacuum Evaporator

A rotary vacuum evaporator operates on the principle of continuous distillation of large amounts of volatile solvents under reduced pressure. The stepless speed regulation feature enables the evaporation flask to rotate at a constant speed, creating a large area of uniform thin film on the inner wall of the flask. The heated water or oil bath heats the evaporation flask evenly while the process feed inside the flask is converted into vapors due to the low boiling point at reduced pressure. The vapors then travel up the vapor tube and into the condenser, where they are cooled and collected.

Applications of a Rotary Vacuum Evaporator

The rotary vacuum evaporator has numerous applications in various industries, including the production of concentrated flavor extracts and distillation of essential oils from herbs and spices in the culinary world. In the chemical and biological fields, it is used to extract chemical substances for further analysis, and in the pharmaceutical industry, it is used to extract CBD, the main component of marijuana for medicinal purposes.

Advantages of a Rotary Vacuum Evaporator

The primary advantage of a rotary vacuum evaporator over traditional distillation is higher efficiency and better accuracy. The device works at low temperatures, making it safe and beneficial for human consumption. Additionally, it operates under high vacuum, reducing solvent boiling points under vacuum considerably and ensuring the original performance of the food material is maintained.

In conclusion, a rotary vacuum evaporator is a versatile laboratory equipment that has proven to be indispensable in various industries. Its ability to remove solvents from a sample mixture, leaving behind a concentrated substance for further analysis, has made it an essential tool in many laboratories and kitchens around the world.

How does a rotary evaporator work?

A rotary vacuum evaporator is a laboratory equipment used to evaporate solvents and purify compounds by removing unwanted contaminants. The process of evaporation is made more efficient and effective through the use of a rotary vacuum evaporator. In this section, we will discuss how a rotary evaporator works.

The Components of a Rotary Evaporator

A rotary evaporator consists of several components, including the evaporation flask, the water/oil bath, the condenser, and the receiving flask. The evaporation flask is a round-bottom flask that contains the raw mixture. It is heated by the water/oil bath as it rotates continuously until all the evaporation has taken place. The vapor then travels through the airtight system to the condenser, consisting of the cooling coils. Here, the vapor is chilled, and the solvent is condensed back to a liquid that flows to the receiving flask, completing the process.

The Working Principle of a Rotary Evaporator

The working principle of a rotary evaporator is based on the assumption that the boiling point of the solvent in question is much lower than the boiling point of the liquid surrounding it. As the boiling point of liquids slowly reduces when you decrease their pressure, it allows the solvent to be vaporized at lower temperatures than their standard boiling point at normal pressure. The other assumption is that the components in the liquid are usually thermally sensitive.

The process involves creating a vacuum space in the rotary glass flask. The vacuum system is essential in the whole process of evaporation as it accomplishes the entire process. The work of the condenser at the other end is to aid in converting the gas back to a liquid form that needs lower temperatures. The rotation of the evaporation flask, immersed in a heated water bath or oil bath, increases the surface area of the product, greatly speeding distillation and also, through forced convection, keeping the mixture evenly mixed and heated to promote stable, even evaporation.

The Benefits of Using a Rotary Evaporator

One of the key benefits of using a rotary evaporator is that it is operated under vacuum condition, which efficiently lowers the boiling points of materials. The relatively low temperature can preserve the original taste of materials. The evaporation flask is rotated by a motor and heated by a water bath or oil bath, increasing the evaporation area and speed the distillation process. The whole process can be clearly observed so that any adjustment can be done in time due to a rotary evaporator is made of transparent glass.

Conclusion

In conclusion, a rotary vacuum evaporator is a valuable tool in the fields of chemistry, biochemistry, pharmaceuticals, and even cooking. By using a rotary vacuum evaporator, the process of evaporation is made more efficient and effective. The working principle of a rotary evaporator is not complicated, but it requires some understanding of the components and their functions. The benefits of using a rotary evaporator are many, including faster and more efficient solvent removal than evaporation under atmospheric pressure, saving time and increasing productivity in the laboratory.

Benefits of using a rotary vacuum evaporator

Rotary vacuum evaporators are versatile laboratory equipment that have found applications in various fields, including chemistry, pharmaceuticals, cooking, and the production of essential oils and perfumes. Here are some of the benefits of using a rotary vacuum evaporator:

Efficient evaporation process

The use of a rotary vacuum evaporator makes the evaporation process more efficient and accurate. The equipment guarantees that all evaporation processes are completed in a vacuum, which lowers the material boiling point. This means that the material does not need to be heated to high temperatures, protecting the original performance of the material. Moreover, the equipment makes the evaporation process more efficient and accurate.

Increased surface area

The evaporating flask of a rotary vacuum evaporator is immersed in a heated water bath or oil bath, which increases the surface area of the product being processed. This greatly speeds up distillation and, through forced convection, keeps the mixture evenly mixed and heated to promote stable, even evaporation.

Recovery of solvents

The rotary evaporator condenser is totally sealed and made of glass that is easy to visually monitor and adjust. This way, almost 100% of the solvent can be recovered. The equipment is particularly useful in removing solvents from samples, making it an essential tool in the drug development process. This process is done under reduced pressure, which lowers the boiling point of the solvents, making it easier to remove them from the sample.

High yields

The use of a rotary vacuum evaporator in the production of essential oils and perfumes results in higher yields than traditional distillation methods. The equipment is particularly useful in extracting volatile compounds from natural sources. This method is preferred over traditional distillation methods as it requires less time and produces higher yields.

Intense and pure flavors

In the culinary industry, rotary vacuum evaporators are used for distilling and concentrating flavors and aromas of food products. This process results in more intense and pure flavors, which are highly sought after by chefs. It is also a gentler way of cooking fresh food while preserving taste, scent, and nutritional facts by spoiling the combination temperature/vacuum.

In conclusion, the benefits of using rotary vacuum evaporators are numerous, making it an essential piece of equipment in various industries. Its ability to distill, concentrate, and extract volatile compounds makes it a valuable tool in the culinary, pharmaceutical, and chemical industries. Moreover, the equipment guarantees efficient evaporation processes, increased surface area, recovery of solvents, high yields, and intense and pure flavors.

Usage of Rotary Evaporator in Cooking

Rotary vacuum evaporators are versatile equipment that can be used in various fields, including cooking. They can be used to enhance the flavor of food and also to concentrate liquids. Below are some ways rotary evaporators are used in cooking.

Flavor Extraction

Chefs use rotary evaporators to extract essential oils from herbs and spices. The process involves placing the herbs or spices in a solvent and then using the rotary evaporator to extract the oils. This process can also be used to extract flavors from fruits and vegetables. The rotary evaporator gently extracts the volatile aroma and flavor molecules from the mixture at low temperatures, resulting in intense and pure flavors.

Concentration

Rotary evaporators can also be used to reduce the water content in sauces and soups, intensifying their flavor. The process involves placing the liquid in a round-bottomed flask and attaching it to the rotary evaporator. As the vacuum evaporates the liquid, it concentrates the flavors, resulting in a more flavorful sauce or soup.

Unique Flavors and Textures in Beverages

Rotary evaporators can also be used to create unique flavors and textures in cocktails and other beverages. As the vacuum evaporates the liquid, it can create a foam or a light and airy texture, which can be used to enhance the appearance and taste of a drink. Chefs and bartenders can use rotary evaporators to create unique cocktails with intense flavors and textures.

Molecular Cooking

Rotary vacuum evaporators are also used in molecular cooking. This innovative method of cooking applies chemical as well as physical cooking techniques to create unique and flavorful dishes. Rotary evaporators are used to extract and distill flavors, creating new and intense flavors. The vacuum system facilitates the wide usage of the device, and the glassware used in it makes it great and durable for use.

In conclusion, rotary vacuum evaporators are versatile equipment that can be used in various fields, including cooking. They can help create unique flavors and textures in food and beverages, and they are an essential tool for any chef looking to elevate their culinary creations.

Rotary Evaporator Cooking Examples

Rotary vacuum evaporators are not only used in chemical laboratories but in cooking as well. The ability to extract essential oils and flavors from fruits, herbs, and vegetables has made them popular among chefs. Here are some examples of how rotary evaporators are used in the culinary world:

Flavored Alcohol

One of the most popular uses of rotary evaporators in cooking is creating flavored alcohol. By placing alcohol and desired ingredients in the rotary evaporator and allowing the vacuum to extract the flavors, infused alcohol can be created. This can be used as a flavoring agent in recipes or even in cocktails.

Essential Oils and Extracts

Rotary evaporators can also be used to extract essential oils and flavors from herbs, fruits, and vegetables. The process allows for a pure and concentrated form of the desired flavor which can be used in various ways in cooking and baking.

Concentrated Broths

Rotary evaporators can also be used to create concentrated broths. By combining the desired ingredients and water in the rotary evaporator and allowing the vacuum to extract the flavors, a concentrated broth can be created. This can be used as a base for soups, stews, and sauces.

Distilled Vinegars

Rotary evaporators can also be used to distill vinegars. By combining the desired vinegar and flavoring ingredients in the rotary evaporator and allowing the vacuum to extract the flavors, a distilled vinegar can be created. This can be used as a unique and flavorful addition to salads and other dishes.

Fruit Juices and Syrups

Rotary evaporators can also be used to create fruit juices and syrups. By placing the desired fruit in the rotary evaporator and allowing the vacuum to extract the flavors, a concentrated juice or syrup can be created. This can be used in various ways in cooking and baking.

In conclusion, rotary vacuum evaporators are versatile pieces of equipment that have found their way into the culinary world. They allow for the extraction of essential oils and flavors from fruits, vegetables, and herbs, as well as the creation of infused alcohols, concentrated broths, distilled vinegars, and fruit juices/syrups. With their ability to create unique and flavorful ingredients, rotary evaporators have become an essential tool for chefs looking to create innovative and creative dishes.

Rotary Evaporator in Coffee-Making

A unique application of the rotary evaporator has been found in the coffee-making industry. By using a rotary evaporator, coffee makers are able to create concentrated coffee extracts that have a more intense and complex flavor profile. Here is how this process works:

Step 1: Preparing the Coffee Solution

The process begins by preparing a coffee solution in the rotary evaporator flask. The solution is made by mixing coffee grounds with water.

Step 2: Evaporation

The flask is then placed on the rotary evaporator, and the vacuum pump is turned on to create a low-pressure environment. The low pressure causes the water content in the coffee solution to evaporate at a low temperature, which preserves the volatile compounds responsible for the coffee's taste and aroma.

Step 3: Condensation

The evaporated water content travels to the condenser chamber, where the coils in there chill the gases turning them into liquid. The liquid is collected in a receiving flask.

Step 4: Final Product

The resulting concentrate can be mixed with water to create a flavorful cup of coffee or used as a flavoring agent in other food and beverage products. The coffee extract has a more intense and complex flavor profile than regular coffee due to the preservation of volatile compounds, which would have been lost if the extraction was done using traditional methods.

Advantages of Using Rotary Evaporator in Coffee-Making

Using a rotary evaporator in coffee-making has several advantages over traditional methods. These include:

- Preservation of volatile compounds responsible for the coffee's taste and aroma

- Production of concentrated coffee extracts with a more intense and complex flavor profile

- Ability to create unique and high-quality coffee products

- The process is relatively quick and efficient compared to traditional methods.

Conclusion

The rotary evaporator has found a unique application in the coffee-making industry. By using this technique, coffee makers can create concentrated coffee extracts that have a more intense and complex flavor profile. The use of rotary evaporators has gained popularity among specialty coffee shops and roasters due to its ability to create unique and high-quality coffee products. The versatility of the rotary vacuum evaporator continues to amaze scientists, chefs, and coffee makers alike, making it an indispensable tool in the laboratory and in the kitchen.

Conclusion: The Versatility of Rotary Vacuum Evaporator

In conclusion, the rotary vacuum evaporator is an incredibly versatile piece of laboratory equipment that has found applications outside of the science lab. The ability to efficiently and effectively remove solvents from a sample has made the rotary evaporator a valuable tool in the culinary arts, specifically in the creation of concentrated flavors and essences. Additionally, the coffee industry has also taken advantage of the rotary evaporator's ability to extract and concentrate flavors to create unique and complex coffee blends. The versatility of the rotary vacuum evaporator extends beyond the laboratory and into other industries, making it a valuable investment for any institution.

Related Products

Related Articles

- Choosing the Right Rotary Vacuum Evaporator for Your Lab

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- How to Choose Laboratory Vacuum Pumps for Maximum Efficiency and Cost Savings

- A Step-by-Step Guide to Using a Rotary Vacuum Evaporator for Solvent Removal

- Exploring the Science Behind Rotary Evaporators: How They Work and Their Applications