Introduction

A rotary evaporator is a laboratory equipment used for distillation and solvent recovery processes. It works by rotating the flask containing the mixture under vacuum, which allows for efficient separation of the components based on their boiling points. The rotary evaporator offers several advantages over traditional distillation methods, including faster distillation times, reduced solvent usage, and improved distillate quality. This makes it an essential tool for various industries, including pharmaceuticals, food and beverage, and chemical manufacturing. In this blog post, we will discuss the factors that affect the efficiency of a rotary evaporator, its working principle, and how it can improve the quality of your distillate.

Table of Contents

What is a Rotary Evaporator?

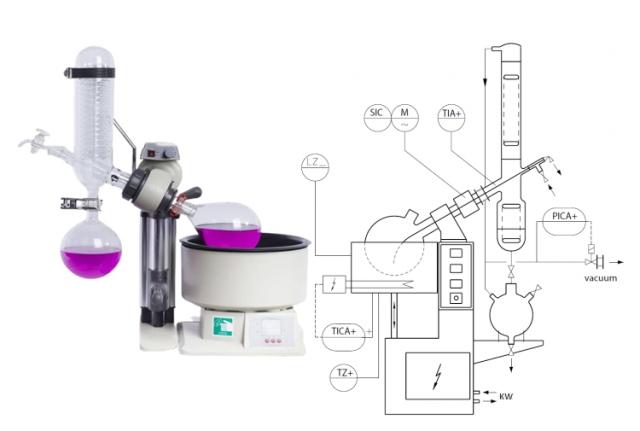

A rotary evaporator, also known as rotovap, is an essential laboratory device used for distillation and purification processes. It is designed to remove solvents from a sample by evaporating them under reduced pressure and low temperatures. The device consists of a vacuum system, a condenser, a heated water or oil bath, and a motor that rotates the evaporation flask. The device is widely used in the chemical, pharmaceutical, and biotechnology industries to separate and concentrate substances, such as essential oils and plant extracts.

Applications of a Rotary Evaporator

A rotary evaporator has a broad range of applications. It is mainly used for continuous distillation of large amounts of volatile solvents under reduced pressure. The device can be used in small and pilot experiments, and it can be applied in the production in the biological, pharmaceutical, chemical, and even food-making industries. In recent years, the application of rotary evaporator has been extended to the cooking industry, where it is used for non-heat evaporation of liquid, thus retaining volatile aromatics that are easily lost by heating.

Working Principle of a Rotary Evaporator

The stepless speed regulation is adopted to make the evaporation flask rotate at a constant speed. By the rotation, materials can form a large area of uniform thin film on the inner wall of the flask. The evaporation flask is heated evenly by a water or oil bath, and materials, with a lower boiling point, is evaporated rapidly under the vacuum condition. The solvent steam is recycled in the receiving flask after being cooled by the high-efficiency glass condenser.

Primary Advantage of a Rotary Evaporator over Traditional Distillation

The primary advantage of using a rotary evaporator over traditional distillation is higher efficiency, together with better accuracy. The device allows for precise control over temperature and pressure, which can help to preserve the delicate compounds and flavors of the sample being distilled. Additionally, the device can significantly improve the quality of your distillate by minimizing the risk of thermal degradation and oxidation that can occur during traditional distillation methods.

Advantages of a Rotary Evaporator

Rotary evaporators are quite popular in the market because they have a great variety of advantages that can help people work efficiently. The device has a built-in lifting motor, which can automatically raise the flask to a position above the heating pot when the power is turned off. Due to the centripetal force and frictional force between the liquid sample and the evaporation bottle, the liquid sample forms a liquid film on the inner surface of the evaporation bottle, and the heated area is large. In this way, rotary evaporator can guarantee a high evaporation efficiency. The feeding system of a rotary evaporator is continuous feeding, which improves the working efficiency of the evaporation system. It is suitable for reflux operation, rapid evaporation of large amounts of solvent, concentration of trace components and reaction processes that require stirring.

Disadvantages of a Rotary Evaporator

Some samples will boil during the heating process, such as heated ethanol and water. Once boiling occurs, the collected sample will be lost. For samples that are particularly difficult to distill, including those that are prone to foaming, a special condenser tube can also be configured for the rotary evaporator. In the rotary evaporator equipment, the glassware needs to be cleaned very often because rotary evaporator needs a totally clean container to guarantee the purity of materials. If there is any impurity in the glassware, the extracted materials will not be pure.

A rotary evaporator is a highly useful device in the distillation processes of cannabis extraction, chemical labs, and biotechnology industries. These sectors incorporate a rotovap into their production cycle due to its efficiency in solvent removal.

Advantages of Rotary Evaporator over Traditional Distillation

Lower Boiling Temperatures

One of the major advantages of rotary evaporators over traditional distillation methods is that they allow the separation of solvents and other compounds at lower temperatures. This is achieved by reducing the pressure of the system through the use of a vacuum system. Additionally, the use of lower water bath temperatures ensures that the apparatus stays in good shape for longer as they are exposed to lower temperatures.

Faster Evaporation of Solvent

The process of separation in rotary evaporators involves two main forces: the centripetal force and friction. These forces act between the evaporation bottle or round-bottomed flask and the liquid mixture, allowing the mixture to form a film on the inner surface of the flask, creating a larger surface area for heating. The rotary evaporator is electronically controlled to enable the rotation of the flask at a constant speed, contributing to an increased surface area, and thus faster evaporation of the solvent. Under the low pressure caused by the vacuum pump, the distillation speed is increased significantly due to the large surface area of the mixture.

Fewer Operations

A rotary evaporator consists of a built-in lifting and falling motor, enabling the automatic raising of the rotary bottle to a position just above the water bath for the rotation process. This means that a technician is less involved in the holding of the apparatus, which makes work easier for them. The motor is electrically powered, and this means that the apparatus can be used so long as there is power. This makes it an efficient and reliable apparatus for most chemistry labs.

Rotary Evaporators Suppress Bumping

The forces that contribute to the evaporation process in rotary evaporators (centripetal force and friction) help to suppress bumping. This allows for quick and gentle evaporation of mixtures, and therefore even inexperienced users can utilize these apparatus. The solvent remaining after the rotary evaporation can further be removed through a deeper vacuum or a tightly sealed vacuum system at ambient or relatively higher temperatures.

Improved Quality of Distillate

The use of rotary evaporators reduces the risk of overheating or damaging the sample, as the evaporator can be easily adjusted to suit the specific needs of the sample being distilled. Additionally, the use of a rotary evaporator reduces the risk of contamination, as the sample is contained within a closed system, minimizing exposure to outside elements. This can greatly improve the quality of the distillate, ensuring that it is pure and free from any unwanted impurities.

In conclusion, a rotary evaporator offers several advantages over traditional distillation methods, such as lower boiling temperatures, faster evaporation of the solvent, fewer operations, and suppressing bumping. These advantages make the rotary evaporator a vital tool in the laboratory, allowing for a more efficient, consistent, and high-quality distillation process.

Factors Affecting Distillation Efficiency of Rotary Evaporator

Vacuum Degree of the Rotary Steaming System

- Vacuum pump power

- System tightness

- Vacuum value that the system can form is determined by the pressure resistance of the equipment of the rotary evaporator and the avoidance of bumping when the distillation efficiency is ensured

- Reasonable vacuum value can be achieved by adjusting the vacuum controller

Sealing Ring

- Connecting the key parts between the evaporation tube and the condensation tube

- Wear resistance and corrosion resistance are the most important performance requirements

- Common materials are PTFE and rubber

- PTFE has better wear resistance and corrosion resistance than rubber

Rotary Heating Power

- The higher the temperature of the oil bath, the faster the distillation rate of the solvent

- Excessive temperature can easily lead to high temperature softening of seals and other components, reducing their service life and reducing the tightness of the system

- Oil bath is heated in a water bath with a temperature setting below 60°C

- Temperature higher than 80°C is heated in an oil bath

Motor Speed

- Larger volume of sample or a faster rotary speed can result in a faster distillation process

- The efficiency of the distillation process can be compromised if the speed is too fast

- The size and speed of the rotary evaporator play a critical role in the efficiency of the distillation process

Design and Quality of the Glassware Used

- Glassware is under extreme pressure due to the vacuum pump as well as being heated

- Coated glassware can be used to ensure flasks don’t shatter during operation

- Glassware quality can affect the efficiency of the distillation process

Vacuum Level Applied During the Distillation

- Vacuum level can affect the efficiency of the distillation process

- It is important to choose a rotary evaporator based on the specific needs of the laboratory and the type of samples being distilled

- Optimizing the variables that affect the efficiency of the distillation process can improve the quality and purity of the distillate.

How Rotary Evaporator Can Improve Distillate Quality

A rotary evaporator is a laboratory instrument that is used for distillation purposes. It has the capability to remove solvents from samples through a process of evaporation. Using a rotary evaporator can improve the quality of distillate in several ways.

More Efficient Distillation Process

The use of a rotary evaporator allows for a more efficient distillation process, which results in a purer end product. The instrument is capable of removing the solvent from the sample at a lower temperature, which reduces the risk of thermal degradation of the sample. This means that the final product is more likely to retain its original properties, such as taste and aroma.

Removal of Impurities

The rotary evaporator can be used to remove impurities that may be present in the sample. This is achieved by separating the different components of the sample, which allows for the removal of unwanted substances. The process ensures that the concentration of the desired components is increased, which leads to a more concentrated, purer end product.

Increased Yield of Distillate

The use of a rotary evaporator can also increase the yield of the distillate. By using the instrument, it is possible to recover more of the solvent, which can be reused in future distillations. This leads to a more sustainable and cost-effective process of distillation.

Reduced Risk of Contamination

Rotary evaporators are designed to operate under vacuum conditions, which reduces the risk of contamination from air and other external factors. This ensures that the quality of the distillate is maintained throughout the process.

Conclusion

In conclusion, the use of a rotary evaporator is an effective way to improve the quality of distillates. Its ability to remove solvents efficiently, reduce the risk of thermal degradation, remove impurities, and increase the yield of the distillate makes it an essential instrument in the field of laboratory equipment.

Conclusion

In conclusion, the rotary evaporator is a powerful and versatile tool for distillation applications. It offers several advantages over traditional distillation methods, including greater efficiency, improved quality of distillate, and reduced processing time. The factors that affect the efficiency of a rotary evaporator include the size of the flask, the speed of rotation, and the temperature of the heating bath. The rotary evaporator is widely used in a variety of applications, including chemistry, pharmaceuticals, and food processing. By using a rotary evaporator, you can improve the quality of your distillate and increase your overall productivity.