Introduction to Rotary Evaporators

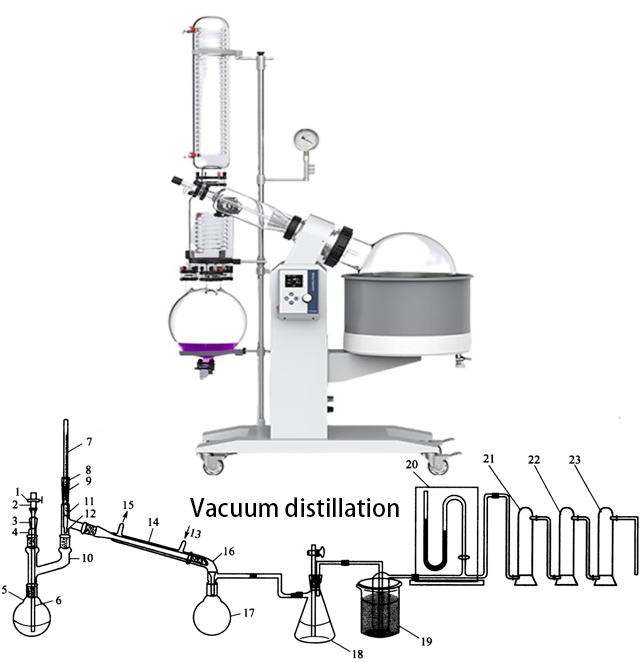

Rotary evaporators, also commonly referred to as rotovaps, are laboratory equipment used for the separation of solvents from a mixture through the process of distillation. They consist of a flask that is rotated to increase the surface area available for evaporation and a condenser that cools the vapors to collect the separated solvent. Rotary evaporators are widely used in various industries such as pharmaceuticals, food and beverage, and chemical manufacturing due to their ability to increase distillation efficiency and reduce processing time. By using a rotary evaporator, users can obtain a higher yield of pure and concentrated samples, making it an essential tool for research and development.

Table of Contents

Function and Operation of a Rotary Evaporator

A rotary evaporator is a vital tool in the field of distillation and is used by scientists and researchers to purify and concentrate complex mixtures. Here's how it works:

Function of a Rotary Evaporator

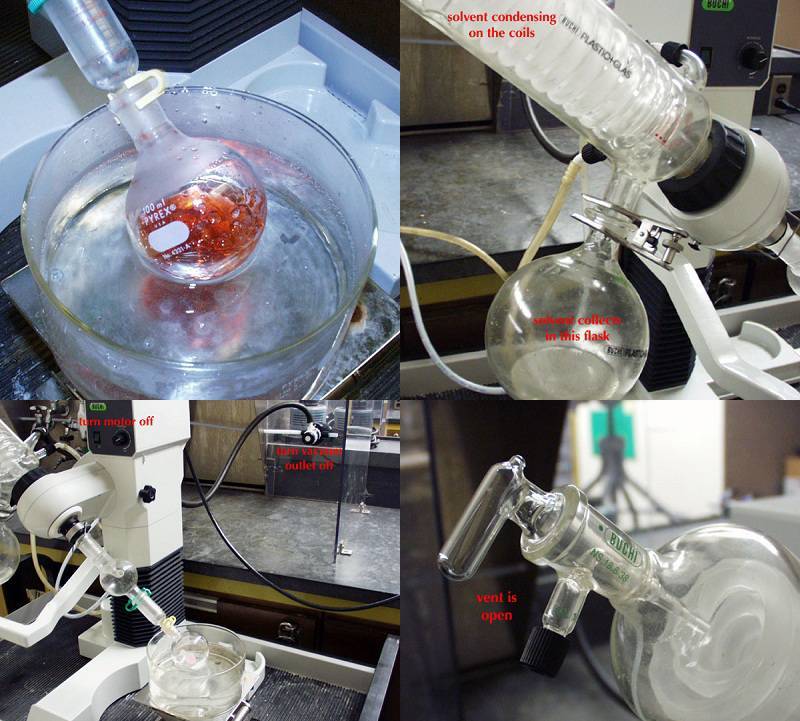

The primary function of a rotary evaporator is to remove solvents from a sample using a vacuum and a rotating flask. The process involves placing the sample in a flask that is rotated at a controlled speed while a vacuum is applied. The reduced pressure causes the solvent to evaporate, and the vapors are condensed and collected in a separate flask. This process can be repeated several times to achieve the desired level of purity.

Operation of a Rotary Evaporator

The operation of a rotary evaporator requires precision and careful attention to detail. Here are the steps involved:

-

Assembling the Rotary Evaporator: The rotary evaporator consists of a vacuum pump and its pipeline, evaporation bottle and receiving bottle, condenser tube, and other components. Assemble the equipment and ensure that the system is airtight.

-

Setting the Vacuum Degree: The vacuum degree is a key factor affecting the distillation efficiency of a rotary evaporator. Adjust the vacuum controller to set a reasonable vacuum value based on the pressure resistance of the equipment and bumping avoidance.

-

Setting the Heating Power: The heating power determines the distillation rate of the solvent. Set the temperature of the oil bath or water bath to a reasonable temperature, avoiding excessive temperature that can lead to decomposition or deterioration of the distilled substance or the softening of seals and other components.

-

Starting the Rotation: Charge the sample into the flask from the feed tube, then start the rotation of the flask. The rotation creates a thin film of process feed on the wall of the rotating flask, ensuring uniform heating across the entire mass and less possibility of bumping.

-

Starting the Heating: Start the heating process. As the process feed gets heated, the low boiler converts into vapors and goes up the vapor tube and into the condenser, where the condensate is formed. This condensate can either be refluxed back into the rotary flask for higher purity applications or collected in the receiver.

![Install the rotary evaporator]()

Advantages of a Rotary Evaporator

Rotary evaporators are revolutionizing the way distillation is performed in laboratories. Here are some of the advantages of using a rotary evaporator:

- Greater precision and accuracy in the separation of complex mixtures

- The ability to control the temperature and pressure during distillation

- Reduced solvent usage, which is cost-effective and environmentally friendly

- Efficient performance and higher accuracy compared to traditional distillation methods

In conclusion, rotary evaporators are a crucial tool in the field of distillation. Understanding their function and operation is crucial for achieving the desired level of purity in complex mixtures.

Factors Affecting Distillation Efficiency

Distillation is a widely used process in various industries such as pharmaceutical, chemical, and food processing. Rotary evaporators have revolutionized the distillation process by making it more efficient, faster, and safer. However, several factors can affect the efficiency of the distillation process. In this section, we will discuss these factors in detail.

Type of Solvent

The type of solvent being used can determine the efficiency of the distillation process. Solvents with low boiling points require less heat energy to evaporate, making them easier to distill. On the other hand, solvents with high boiling points require more heat energy and time to evaporate, making them difficult to distill.

Quality and Design of the Evaporator

The quality and design of the evaporator can also affect the efficiency of the distillation process. Modern rotary evaporators are designed with advanced features that optimize the evaporation process, such as digital temperature control, automatic vacuum control, and safety features. The quality of the evaporator is also important, as it affects the durability and reliability of the equipment.

Sample Volume

The volume of the sample being distilled is a crucial factor in determining the efficiency of the process. Smaller volumes evaporate faster and are easier to handle than larger volumes. It is important to choose the correct size of the evaporator based on the volume of the sample to be distilled.

Temperature and Pressure

The temperature and pressure of the environment in which the distillation takes place also play a vital role in the efficiency of the process. The temperature should be high enough to facilitate the evaporation of the solvent but low enough to prevent the sample from boiling. The presence of a vacuum decreases the pressure within the system. This decreases the vapor pressure required for boiling to occur, thus lowering the boiling point of the solvent. This means less heat energy is needed for it to evaporate.

Rotation of the Flask

The rotation of the flask plays an important role in a rotary evaporation setup for two major reasons: increased surface area of the solvent and agitation of the water bath liquid. In a rotating flask, the solvent forms a thin film around the sides of the flask, greatly increasing the surface area and speeding up evaporation.

In conclusion, understanding the factors that affect the efficiency of the distillation process can help researchers and laboratory professionals optimize their distillation processes. These factors include the type of solvent, quality and design of the evaporator, sample volume, temperature, pressure, and rotation of the flask. By considering these factors, researchers can achieve more efficient, faster, and safer distillation processes.

Advantages of Rotary Evaporators

Rotary evaporators have been revolutionizing the distillation process in various industries such as pharmaceuticals, biotechnology, and chemical laboratories. The unique design of rotary evaporators offers several advantages over traditional distillation methods.

Reduced Pressure Distillation

Rotary evaporators use a rotating flask and a vacuum to reduce the pressure and lower the boiling point of the solvent. This results in faster and more efficient distillation, as well as the ability to distill at lower temperatures. This is particularly useful for heat-sensitive compounds as it minimizes the risk of thermal degradation and preserves the quality of the material being distilled.

Fast and Efficient Distillation

The rate of evaporation is fast, and separation can be done in a very short time. Compared to its closest rival, distillation, the rotary evaporator is faster, yielding the desired ends within a shorter duration of time. This cuts down the otherwise long wait times you have to put in to be able to enjoy the benefits that come along.

Precise Temperature Control

Rotary evaporators are equipped with a range of features such as digital temperature control, automatic shut-off, and variable speed control, which make them easy to use and highly accurate. These features allow for precise temperature control, which is essential for the distillation of complex mixtures.

Space-Saving Design

The compact design of rotary evaporators makes them ideal for use in small laboratories or in situations where space is limited. The stand-alone heating bath guarantees maximum safety in operations and easy maintenance. It can be completed with the KINTEK vacuum and cooling accessories to reach top efficiency of the process.

Energy-Efficient

Rotary evaporators save a great deal of energy as they negate the need to heat the solution to the boiling point. Instead, they lower the pressure of the fluid in such a way as to make its boiling point lower. For this reason, you will not have to dig deep into your pocket to operate it, making it an excellent choice for those looking to save on energy costs.

Convenient Controls and Safety Features

Rotary evaporators are simple and easier to control, and they come equipped with a set of convenient controls for your use and leverage. They are also fitted with tons of safety devices and features that minimize explosions, overheating, short-circuits, and other likely dangers. Moreover, they enjoy a relatively safe track record, ensuring your safety and peace of mind.

In conclusion, the advantages of rotary evaporators make them an essential tool for anyone involved in distillation or purification of compounds. They offer reduced pressure distillation, fast and efficient distillation, precise temperature control, energy efficiency, convenient controls, and safety features, all in a compact and space-saving design.

Rotary Evaporators in Various Industries

Rotary evaporators have become an indispensable tool in various industries due to their efficiency, cost-effectiveness, and safety. Here are some of the industries that have been revolutionized by the use of rotary evaporators.

Pharmaceutical Industry

The pharmaceutical industry uses rotary evaporators to extract and separate active ingredients from plant materials. This is essential for the production of medicines. Rotary evaporators help to increase the concentration of the active ingredient, making the extraction process more efficient. This results in higher yields of the active ingredient, making the production of medicines more cost-effective.

Food and Beverage Industry

In the food and beverage industry, rotary evaporators are used to extract flavors and fragrances from natural sources such as fruits and herbs. These flavors and fragrances are used to enhance the taste and aroma of food products. Rotary evaporators have revolutionized this process by providing a more efficient and cost-effective way of extracting flavors and fragrances.

Chemical Processing Industry

In the chemical processing industry, rotary evaporators are used to purify chemicals and solvents, improving the quality of the end product. Rotary evaporators help to remove impurities and contaminants from the chemical and solvent mixture, resulting in a purer and higher quality end product.

Research and Development

Rotary evaporators are widely used in research and development to isolate and study individual components of complex mixtures. They are used in the analysis of essential oils, for example, to separate the different components of the oil. Rotary evaporators have revolutionized the research and development process by providing a more efficient and cost-effective way of isolating and studying individual components.

Cannabis Extraction

Rotary evaporators are highly useful in the distillation processes of cannabis extraction. The cannabis industry has incorporated rotary evaporators into their production cycle due to its efficiency in solvent removal. The ability to reclaim both the solvent and sample is important for both the bottom line and the environment.

In conclusion, rotary evaporators have become a game-changer in various industries by providing a more efficient, time-saving, and cost-effective solution to separation techniques. They have proven to be a valuable tool in the pharmaceutical, food and beverage, chemical processing, research and development, and cannabis extraction industries.

Conclusion: The Revolution of Distillation with Rotary Evaporators

In conclusion, rotary evaporators are revolutionizing the distillation process in various industries. Their ability to achieve high levels of efficiency and accuracy in distillation, as well as their ability to handle a wide range of solvents and samples, make them invaluable tools for research and production. Rotary evaporators have also made the distillation process more sustainable by reducing energy consumption and waste production. As the demand for high-quality, pure compounds continues to rise, rotary evaporators will continue to play a crucial role in the distillation process.

Related Products

Related Articles

- What Is Multiple Effect Evaporator?

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- Understanding the Science Behind Short Path Distillation

- What Is Boiling Point Rise In Evaporators?

- Comparing the Features of Laboratory Waterbaths: A Guide to Finding the Right Waterbath for Your Needs