Introduction to Rotavapor

A Rotavapor, also known as a rotary evaporator, is a laboratory apparatus used for distillation, purification, and extraction of solvents. It consists of a heating bath, rotation flask, and a condenser, which work together to remove the solvent from a sample. The sample is placed in the rotation flask, and the solvent is evaporated by heating the flask and rotating it at the same time. The evaporated solvent is then condensed and collected in a separate flask, leaving behind a concentrated sample. The Rotavapor is an essential tool in many industries, including pharmaceuticals, food and beverage, and chemical research. It provides a quick and efficient way to extract and purify compounds, saving time and resources in the process.

Table of Contents

How Rotavapor Works

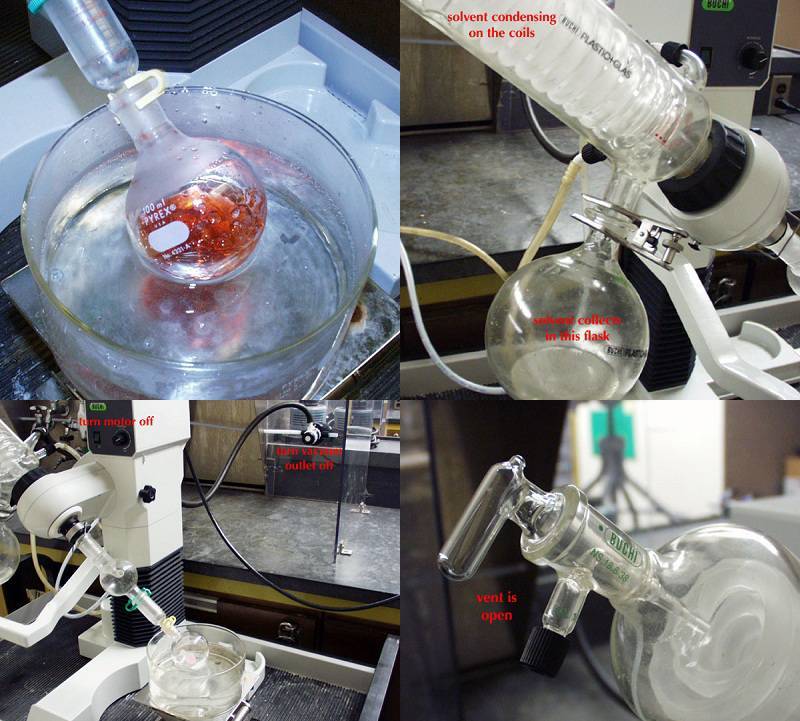

Rotavapor, also known as a rotary evaporator, is a laboratory equipment that is designed to improve the distillation process and save you time. The equipment uses a gentle method to achieve a similar outcome as traditional distillation by lowering the pressure of the sample's environment using a vacuum, which lowers the boiling point significantly. This allows for the separation of the components of the mixture at lower temperatures, resulting in a faster and more efficient process.

Step 1: Increasing Surface Area

A motor moves the flask in a circular motion to increase the surface area of your sample. As the flask turns, the liquids are stretched by the shape of the flask and the motion, increasing surface area.

Step 2: Vacuum Pump

A vacuum pump is used to minimize the pressure on your system. Reducing pressure lowers the boiling temperature, resulting in faster evaporation.

Step 3: Heating or Boiling Your Sample

A bath is used to heat or boil your sample. The sample is placed in a flask, which is then lowered into the bath. The bath is typically filled with hot water, which heats the sample.

Step 4: Cooling with a Condenser

A condenser is used to hold your coolant mixture, like dry ice and acetone, which cools the vapors that condense and are collected in the receiving flask. The process of cooling the vapors back into a liquid is called condensation.

Step 5: Lifting or Sinking the Flask

A mechanical or motorized system is used to lift your evaporation flask from the heating bath or sink it as your experiment process requires, for larger sample sizes.

Using the Rotavapor can save you time and increase the accuracy of your distillation process. The system is fully automated, allowing for precise control of temperature and pressure, and reducing the risk of human error. Additionally, the system is designed to be easy to use, with intuitive controls and a simple setup process.

In conclusion, the Rotavapor is an essential tool for improving the efficiency and accuracy of your distillation process. It can be used for a range of applications, including the distillation of solvents, the purification of natural products, and the preparation of samples for analysis. Whether you are working in a research laboratory, a pharmaceutical company, or a chemical plant, the Rotavapor is an excellent choice to increase productivity and save time.

Benefits of Using Rotavapor

A Rotavapor is a rotary evaporator that offers several benefits to traditional distillation methods. Below are the benefits of using Rotavapor for your distillation process:

Time Savings

Traditional distillation methods can be time-consuming and labor-intensive. However, a Rotavapor can reduce the amount of time required for distillation processes. The vacuum and spinning flask create a more efficient separation of components, leading to better yields of desired products.

Improved Efficiency

The vacuum and spinning flask of a Rotavapor create a more efficient separation of components, leading to better yields of desired products. Additionally, the ability to control temperature and pressure during the distillation process allows for a more targeted separation of components, resulting in greater accuracy and product purity.

Better Product Yields

By reducing the amount of time required for traditional distillation methods, a Rotavapor can improve overall laboratory productivity. Additionally, the vacuum and spinning flask create a more efficient separation of components, leading to better yields of desired products. This ensures that the maximum amount of product is recovered.

Precision Control

A Rotavapor offers precision control over temperature and pressure during the distillation process. This allows for a more targeted separation of components, resulting in greater accuracy and product purity. The precision control also allows for the distillation of heat-sensitive compounds.

Safer Distillation Process

A Rotavapor offers a safer distillation process by reducing the risk of exposure to hazardous materials. The vacuum system reduces the boiling temperature of the solvent, which reduces the risk of overheating or explosion. Additionally, the closed system reduces the risk of exposure to the solvent or other hazardous materials.

In conclusion, the benefits of using a Rotavapor for your distillation process include time savings, improved efficiency, better product yields, precision control, and a safer distillation process. By incorporating a Rotavapor into your laboratory equipment, you can improve the effectiveness and efficiency of your distillation process, saving you time and resources.

Applications of Rotavapor in Different Industries

Pharmaceutical Industry

Rotavapor is widely used in the pharmaceutical industry to extract and purify active ingredients in drugs. This equipment is highly efficient and precise, making it an ideal choice for pharmaceutical professionals. The rotavapor is used to separate solvents from a mixture through the use of heat and vacuum, ensuring high-quality results. It is also environmentally friendly since it reduces the amount of solvent used in the distillation process.

Food and Beverage Industry

In the food and beverage industry, rotavapor is used to extract flavors and fragrances from natural sources. This is necessary in the production of high-quality food products. Rotavapor is highly efficient and saves time by completing the distillation process faster than traditional methods. This equipment is easy to use and highly precise, reducing the likelihood of errors.

Chemical Manufacturing Industry

Rotavapor is also widely used in the chemical manufacturing industry to separate and purify chemicals that are used in the production process. The equipment is highly efficient and precise, ensuring high-quality results. It saves time by completing the distillation process faster than traditional methods. Furthermore, the equipment is environmentally friendly since it reduces the amount of solvent used in the distillation process.

Cannabis Extraction Industry

Rotavapor is a highly useful device in the distillation processes of cannabis extraction. It is used for the removal of solvents samples through the evaporation process. It is highly efficient and saves time by completing the distillation process faster than traditional methods. The vacuum system also facilitates the wide usage of the device.

Molecular Cooking Industry

The application of rotavapor has been extended to the cooking industry through molecular cooking. It is used to non-heat evaporate liquid, thus retaining volatile aromatics that are easily lost by heating. This is perfect for modern culinary and experimental instruments.

In conclusion, rotavapor is a valuable tool that can improve the distillation process in various industries. Its efficiency, precision, and environmental friendliness make it a go-to choice for professionals in the laboratory equipment field.

How to Operate a Rotavapor

To operate a Rotavapor, you need to follow these steps:

Step 1: Set up the Apparatus

To begin, set up the Rotavapor apparatus correctly. This includes installing the cooling water supply and connecting the vacuum pump.

Step 2: Add the Mixture

Next, add the mixture to be distilled into the flask and connect it to the Rotavapor.

Step 3: Turn on the Vacuum Pump

Turn on the vacuum pump, and the mixture is heated to the desired temperature.

Step 4: Adjust the Rotation Speed

Adjust the rotation speed to ensure that the mixture is evenly distributed, and the solvent is evaporated at a consistent rate.

Step 5: Allow the Rotavapor to Run

Allow the Rotavapor to run until the distillation process is complete, and the collected solvent is removed.

By following these steps, you can use the Rotavapor to separate different solvents from a mixture efficiently and accurately.

Conclusion

In conclusion, a rotavapor is an efficient and time-saving tool for distillation processes in various industries. It provides several benefits such as reduced solvent usage, increased productivity, and improved safety. Learning how to properly operate a rotavapor is crucial to achieving the best results. By using a rotavapor, industries can save time and resources, and ultimately improve the quality of their products. With its versatility and ease of use, a rotavapor is a valuable investment for any laboratory or industrial setting involved in distillation processes.

Related Products

Related Articles

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- Why Tap Water Chilling Is Not Enough for Your Rotavap

- How Rotary Evaporator Can Improve the Quality of Your Distillate

- How Rotary Evaporators are Revolutionizing Distillation

- Understanding the Science Behind Short Path Distillation