Traditional Extraction and Separation Technologies

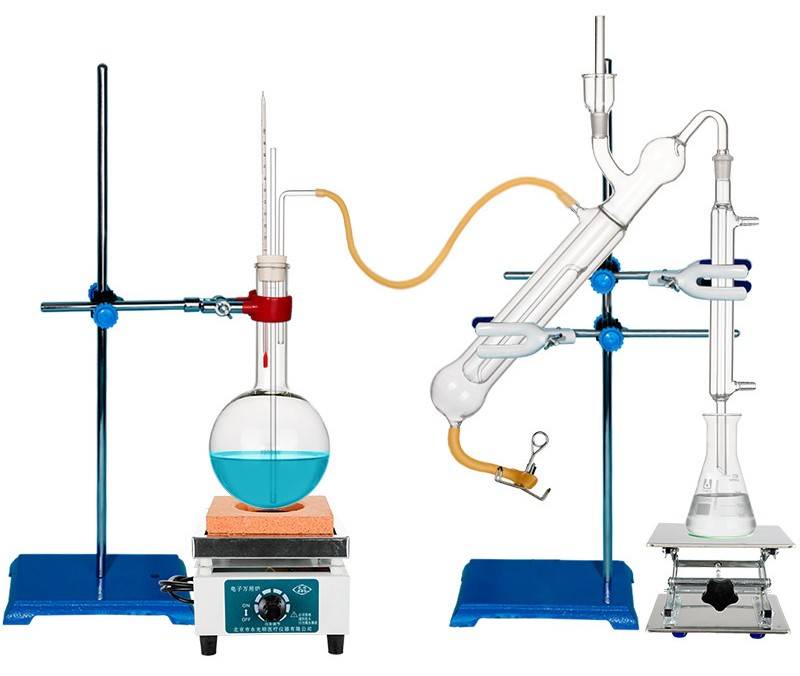

Water Vapor Distillation

Water vapor distillation is a widely used method for extracting essential oils from aromatic plants, known for its simplicity and cost-effectiveness. This technique involves heating plant materials in the presence of water, which vaporizes and carries the essential oils along with it. The vapors are then condensed back into liquid form, allowing the separation of the essential oils from the water. This method is particularly favored due to its straightforward equipment requirements and the relatively high yield of essential oils it produces.

However, water vapor distillation is not without its limitations. Certain plant materials, such as those that are easily dissolved, hydrolyzed, or decomposed in boiling water, present challenges. For instance, delicate flowers and certain fruits may lose their aromatic compounds or degrade under the high temperatures required for this process. This degradation can result in a loss of the desired fragrance and therapeutic properties, making water vapor distillation less suitable for these types of plant materials.

| Advantages | Limitations |

|---|---|

| Simple equipment | Not suitable for easily dissolved, hydrolyzed, or decomposed plant materials |

| Low cost | May degrade delicate aromatic compounds |

| High yield | Requires careful temperature control |

In summary, while water vapor distillation offers a practical and economical solution for many aromatic plants, its application is limited by the sensitivity of certain plant materials to high temperatures. Understanding these limitations is crucial for selecting the most appropriate extraction method for different types of plants.

Leaching Method

Leaching is a versatile extraction technique that employs volatile organic solvents to dissolve and isolate aromatic components from plant materials. This method is particularly effective for extracting essential oils from delicate flowers, resins, and certain fruits, where the integrity of the aromatic compounds must be preserved.

The process of leaching encompasses several key techniques, each tailored to specific types of plant materials and desired outcomes:

-

Fixed Leaching: This method involves immersing the plant material in a fixed position within the solvent. It is ideal for materials that release their aromatic compounds slowly, ensuring a thorough extraction over time.

-

Stirring Leaching: By continuously stirring the plant material and solvent mixture, this technique accelerates the dissolution process. It is particularly useful for plant materials that require mechanical agitation to release their aromatic components.

-

Rotating Leaching: This method employs a rotating mechanism to expose the plant material to the solvent from all angles. It is effective for materials with complex structures that need uniform solvent exposure.

-

Countercurrent Leaching: This advanced technique uses a countercurrent flow system where the solvent and plant material move in opposite directions. It maximizes the extraction efficiency by continuously exposing fresh solvent to the plant material, ensuring that all aromatic compounds are dissolved.

Each of these leaching methods offers unique advantages, making leaching a flexible and powerful tool in the extraction of natural plant flavors.

Pressing Method

The pressing method is a specialized technique employed for the extraction of essential oils from citrus plants. This method operates at room temperature, a critical factor that preserves the authenticity and integrity of the aroma. By avoiding high temperatures, the pressing method ensures that the volatile compounds responsible for the distinctive citrus scent remain unaltered, resulting in a pure and unadulterated essential oil.

Common techniques within the pressing method include whole fruit cold grinding and screw pressing. Whole fruit cold grinding involves pulverizing the entire citrus fruit at low temperatures to extract the essential oils, while screw pressing utilizes a mechanical screw mechanism to apply pressure to the fruit peel, releasing the oils. Both methods are designed to maximize the yield of essential oils while minimizing the degradation of aromatic compounds.

| Technique | Description | Advantages |

|---|---|---|

| Whole Fruit Cold Grinding | Pulverizing the entire citrus fruit at low temperatures to extract essential oils. | Preserves the integrity of the aroma by avoiding high temperatures. |

| Screw Pressing | Using a mechanical screw mechanism to apply pressure to the fruit peel, releasing the oils. | Efficient and effective in extracting high-quality essential oils. |

These techniques are particularly favored for their ability to maintain the natural properties of citrus essential oils, making them a preferred choice in industries where the purity and quality of the aroma are paramount.

Absorption Method

The absorption method is a sophisticated technique that employs non-volatile solvents or solid adsorbents to capture aromatic components from plant materials. This method is particularly well-suited for delicate flowers such as jasmine and orchids, which require gentle handling to preserve their nuanced and high-quality aromas. Unlike methods that involve high temperatures or mechanical stress, the absorption method ensures that the fragile chemical structures of these delicate flowers remain intact, thereby maintaining the integrity and purity of the extracted aromas.

In the process, non-volatile solvents, which do not easily evaporate, are used to dissolve and retain the aromatic compounds. These solvents are carefully selected based on their ability to interact with and stabilize the volatile molecules present in the plant material. Solid adsorbents, on the other hand, act as sponges, absorbing the aromatic components onto their surfaces. This dual approach allows for a comprehensive capture of both water-soluble and lipid-soluble aromatic compounds, ensuring a rich and complex final product.

The absorption method is not only effective for extracting high-quality aromas but also offers a sustainable alternative to more aggressive extraction techniques. By minimizing the use of heat and mechanical forces, it reduces the risk of degrading the delicate compounds that contribute to the unique scents of flowers like jasmine and orchids. This method is thus a cornerstone in the production of premium aromatic products, where the preservation of natural essence is paramount.

Crystallization Method

Cryocrystallization is a specialized technique employed to isolate specific compounds within essential oils through controlled low-temperature freezing. This method is particularly advantageous due to its minimal environmental impact, making it an eco-friendly alternative to more traditional extraction processes. However, the efficiency of cryocrystallization is constrained by the necessity for multiple purification steps, which can be both time-consuming and resource-intensive.

To better understand the application and limitations of cryocrystallization, it is useful to compare it with other extraction methods:

| Extraction Method | Environmental Impact | Efficiency | Suitability for Heat-Sensitive Substances |

|---|---|---|---|

| Water Vapor Distillation | Moderate | High | Limited (due to boiling water) |

| Leaching Method | High (solvent use) | High | Suitable |

| Pressing Method | Low | High | Excellent (room temperature operation) |

| Absorption Method | Low | Moderate | Excellent (non-volatile solvents) |

| Cryocrystallization | Low | Low | Excellent (low-temperature process) |

Despite its lower production efficiency, cryocrystallization remains a valuable tool in the arsenal of natural flavor extraction, particularly when the preservation of delicate compounds and environmental considerations are paramount.

Emerging Extraction and Separation Technologies

Molecular Distillation

Molecular distillation is a specialized form of vacuum distillation that operates under extremely low pressure, typically below 0.01 torr (1.3 Pa). This technique is particularly advantageous for processing high molecular weight and high boiling point substances, as it minimizes thermal degradation and allows for efficient separation and purification.

In molecular distillation, the vacuum environment ensures that the mean free path of molecules is comparable to the size of the equipment, leading to a free molecular flow regime. This regime means that the gaseous phase exerts negligible pressure on the substance being evaporated, thereby decoupling the rate of evaporation from pressure. Consequently, the process relies on molecular dynamics rather than fluid dynamics, necessitating a short path between the hot and cold surfaces to facilitate efficient transfer.

This method is extensively utilized in various industries, including chemical, pharmaceutical, and light industries, for the purification of oils and the concentration of thermally sensitive molecules such as vitamins and polyunsaturated fatty acids. The high vacuum (around 10−4 mmHg) and low temperatures in the distillation column, combined with a small distance (typically around 2 cm) between the evaporator and condenser, ensure that the distillate liquid is exposed to high temperatures for a short duration, preserving its integrity.

Molecular distillation stands out for its ability to handle complex and sensitive compounds, making it a valuable tool in the extraction and separation of natural plant flavors, particularly those that are prone to degradation under conventional distillation methods.

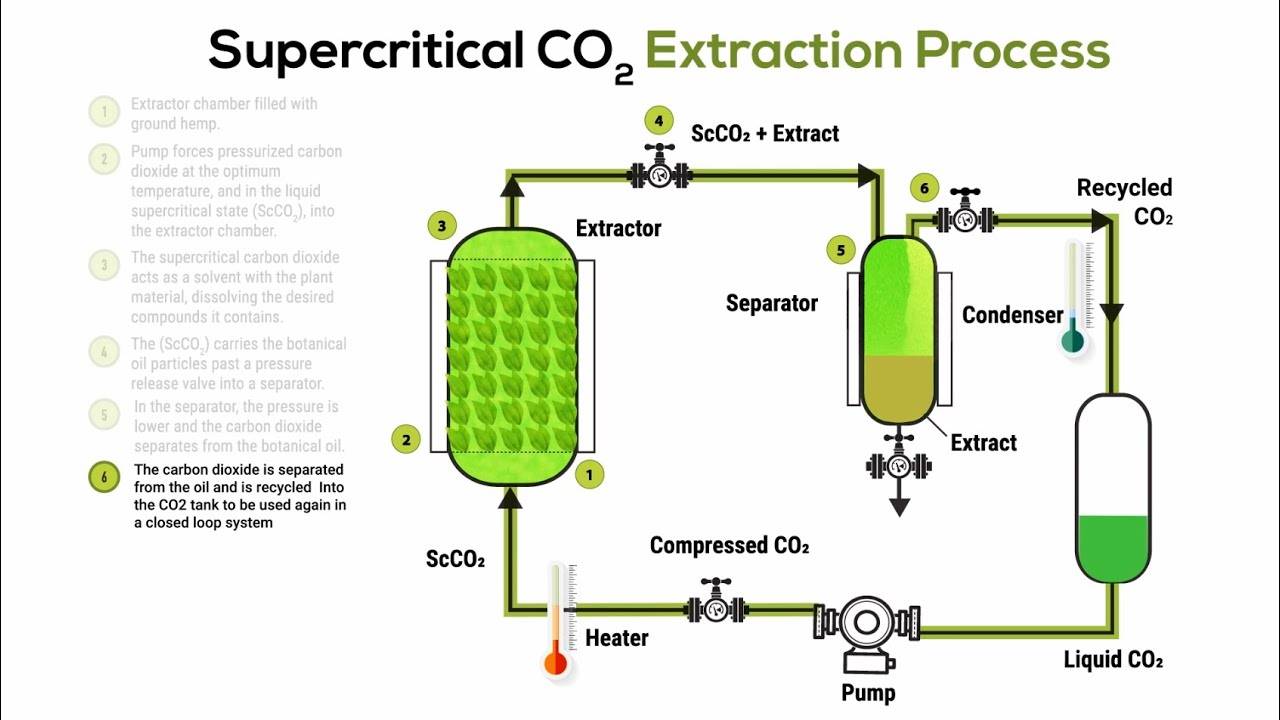

Supercritical CO2 Extraction Technology

Supercritical CO2 extraction technology harnesses the unique properties of carbon dioxide (CO2) in its supercritical state to serve as an efficient and environmentally benign solvent. This method involves pressurizing CO2 to a point where it transitions from a gaseous to a supercritical fluid state, characterized by properties of both gas and liquid. This state allows CO2 to penetrate plant materials effectively, dissolving and extracting valuable compounds such as terpenes and other aromatic components.

The process begins with the introduction of CO2 into a high-pressure chamber containing the plant material. The supercritical CO2 permeates the plant matter, selectively extracting the desired compounds. Once the extraction is complete, reducing the pressure causes the CO2 to evaporate, leaving behind a concentrated extract devoid of any residual solvent. This phase transition is a critical aspect of the process, ensuring the purity and quality of the final product.

One of the significant advantages of supercritical CO2 extraction is its ability to fine-tune the extraction parameters, such as temperature and pressure, to achieve specific outcomes. For instance, adjusting these variables can preserve the full terpene profile of the plant, which is crucial for maintaining the aroma and therapeutic properties of the extract. This adaptability makes supercritical CO2 extraction particularly valuable in industries like cannabis, where preserving the integrity of the terpenes is paramount.

Moreover, the technology incorporates sophisticated systems that facilitate the recycling of CO2. Chillers condense the gas back into a liquid state, while recirculating heaters assist in removing CO2 from the extract, enhancing efficiency and sustainability. This closed-loop system not only minimizes waste but also reduces operational costs and environmental impact.

In summary, supercritical CO2 extraction stands out for its high efficiency, environmental safety, and the ability to produce high-quality extracts with precise control over the final product's composition. Its applications extend beyond hops and valuable plant spices to include cannabis and other aromatic plants, making it a versatile and powerful tool in the realm of natural flavor extraction.

Microwave-Assisted Extraction Technology

Microwave-assisted extraction (MAE) stands out as a cutting-edge method for extracting valuable components from plant materials. This technology leverages the unique properties of microwaves to rapidly heat and selectively extract target compounds, significantly reducing extraction time compared to traditional methods. The process is not only time-efficient but also energy-efficient, making it an environmentally friendly alternative.

One of the key advantages of MAE is its high selectivity, which allows for the targeted extraction of specific compounds without extensive degradation of the plant matrix. This selectivity is achieved through the differential heating of components within the plant material, where polar compounds absorb microwave energy more effectively than non-polar ones. This differential absorption results in localized heating, which enhances the diffusion of target compounds into the solvent.

Moreover, MAE can be integrated with various solvents, including water, ethanol, and hexane, depending on the polarity of the target compounds. This versatility makes MAE suitable for a wide range of plant materials, from delicate flowers to robust herbs. The rapid heating and cooling cycles typical of MAE also minimize thermal degradation, preserving the integrity and quality of the extracted compounds.

In summary, microwave-assisted extraction offers a fast, efficient, and selective approach to plant component extraction, making it a valuable tool in the arsenal of natural flavor and essential oil production.

Accelerated Solvent Extraction

Accelerated Solvent Extraction (ASE) represents a significant advancement in the field of solvent-based extraction techniques. Unlike traditional methods that rely on extended extraction times and higher solvent usage, ASE employs elevated temperatures and pressures to expedite the process. This approach not only enhances the extraction rate but also reduces the overall solvent consumption, making it a more sustainable option.

However, despite its efficiency and environmental benefits, ASE is not as widely adopted in the extraction of natural products as one might expect. This can be attributed to several factors, including the initial investment required for specialized equipment and the method's relatively limited application in certain types of plant materials. For instance, while ASE is highly effective for extracting compounds from robust plant tissues, it may not be as suitable for delicate flowers or heat-sensitive materials where other methods like supercritical CO2 extraction or ultrasonic extraction might be preferred.

The efficiency of ASE lies in its ability to rapidly penetrate plant matrices, thereby reducing extraction times from hours to mere minutes. This is achieved by creating a high-pressure environment that allows solvents to maintain a liquid state at temperatures significantly above their normal boiling points. Consequently, the solubility of target compounds increases, facilitating their rapid dissolution into the solvent.

Despite its advantages, ASE faces challenges in terms of its applicability to natural product extraction. The method's high operating pressures and temperatures can sometimes lead to the degradation of thermally sensitive compounds, which is a critical consideration in the preservation of natural flavors and aromas. Additionally, the method's complexity and the need for specialized equipment may deter smaller-scale operations or those with limited budgets from adopting it.

In summary, while Accelerated Solvent Extraction offers a promising blend of efficiency and reduced solvent usage, its application in natural product extraction remains somewhat limited. Future research and technological advancements may help to address some of these challenges, potentially broadening its use in the extraction of natural plant flavors.

Ultrasonic Extraction Method

Ultrasonic extraction leverages the power of ultrasound waves to significantly enhance the penetration of solvents into plant materials, thereby boosting the efficiency of the extraction process. This method is particularly effective due to the mechanical and thermal effects induced by ultrasonic waves, which cause microscopic cavitation bubbles within the solvent to collapse, generating localized high-temperature and high-pressure conditions. These conditions facilitate the disruption of cell walls, allowing for more effective release and dissolution of target compounds into the solvent.

The application of ultrasonic extraction spans across various industries, with notable prominence in the food and traditional Chinese medicine sectors. In the food industry, it is employed to extract flavors and bioactive compounds from a wide array of plant sources, ensuring the preservation of natural aromas and nutritional values. Similarly, in traditional Chinese medicine, ultrasonic extraction aids in the efficient extraction of medicinal components from herbs, enhancing the efficacy and purity of the final product.

Compared to traditional extraction methods, ultrasonic extraction offers several advantages, including reduced extraction time, lower solvent consumption, and improved yield of target compounds. Moreover, it is a versatile technique that can be integrated with other extraction methods, such as supercritical CO2 extraction and microwave-assisted extraction, to further optimize the extraction process. This versatility makes ultrasonic extraction a valuable tool in the quest for more efficient and sustainable natural product extraction technologies.

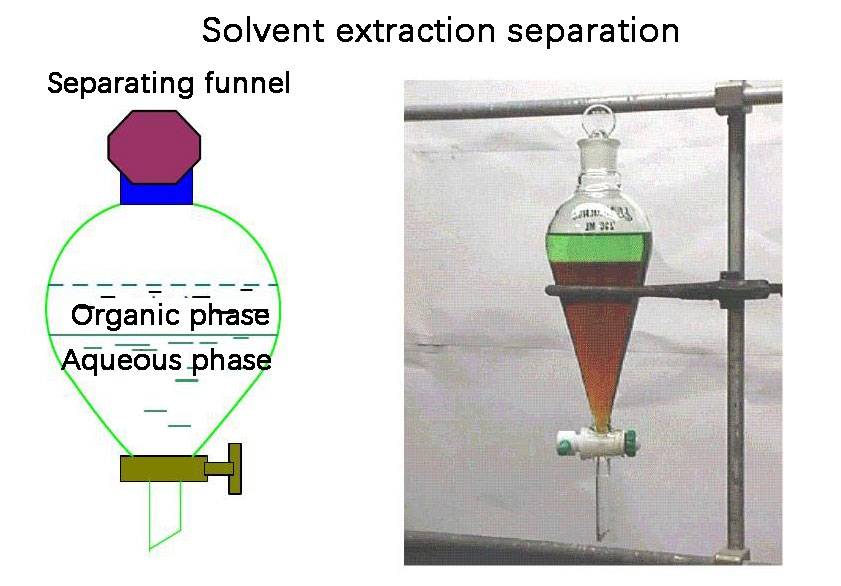

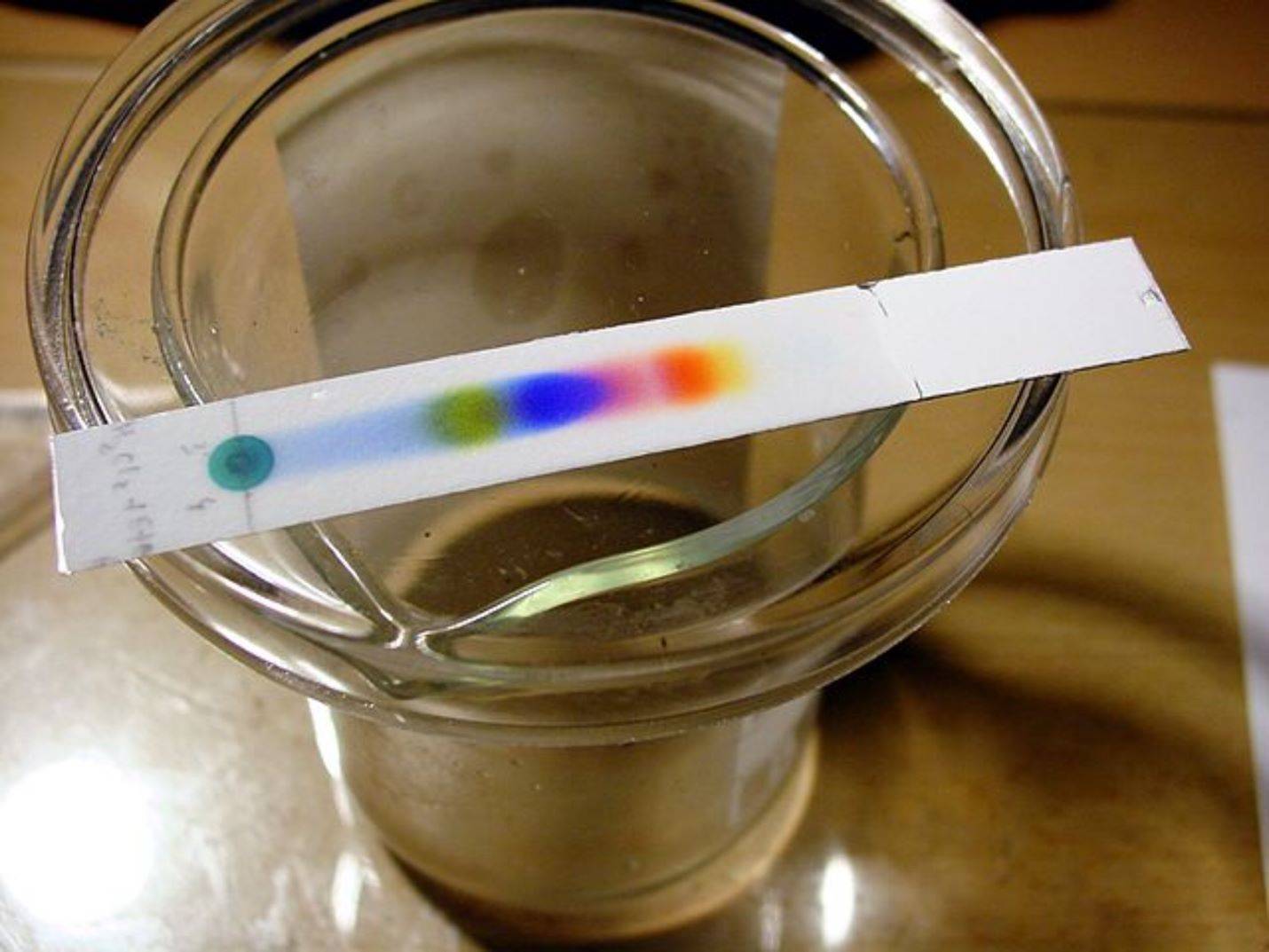

Chromatography

Chromatography stands as a pivotal technique in the realm of natural flavor separation, offering a versatile array of methods tailored to different types of compounds. Among these, thin-layer chromatography (TLC), column chromatography, and counter-current chromatography are particularly noteworthy.

Thin-layer chromatography is a cost-effective and straightforward method, often used for preliminary analysis and identification of volatile and non-volatile components. It involves the use of a thin layer of adsorbent, typically silica gel or alumina, spread on a glass plate. The sample is applied to the bottom of the plate, and as the solvent moves up the plate, different compounds separate based on their affinity for the stationary phase.

Column chromatography, on the other hand, is more robust and suitable for larger-scale separations. It employs a column packed with an adsorbent material, through which the sample mixture is passed. The components of the mixture travel through the column at different rates, depending on their interaction with the stationary phase, leading to their separation.

Counter-current chromatography is an advanced technique that utilizes the difference in solubility of compounds between two immiscible liquid phases. This method is particularly effective for separating compounds that are difficult to resolve using traditional chromatographic techniques. It offers high resolution and can handle a wide range of sample sizes, making it a valuable tool in natural product research.

These chromatography methods are indispensable in the separation of both volatile and non-volatile components of natural flavors, contributing significantly to the purity and quality of the final product.

Other Separation Methods

In addition to the more traditional and emerging extraction techniques, several other separation methods have gained traction in the field of natural plant flavor extraction. These methods, including membrane separation and capillary electrophoresis, offer distinct advantages that make them particularly suitable for specific applications.

Membrane separation is a process that uses semi-permeable membranes to separate molecules based on their size, charge, or other properties. This method is highly effective for isolating heat-sensitive substances, as it operates under mild conditions and consumes relatively low energy. Membrane separation can be particularly beneficial when dealing with delicate plant materials that could be compromised by more aggressive extraction methods.

On the other hand, capillary electrophoresis is a technique that uses an electric field to separate charged molecules based on their migration speed through a narrow capillary tube. This method is highly efficient and can provide detailed analysis of complex mixtures, making it ideal for separating and identifying various components within natural plant flavors. Capillary electrophoresis is also notable for its low sample and reagent consumption, further enhancing its appeal in the field of natural product extraction.

Both membrane separation and capillary electrophoresis contribute to the growing arsenal of techniques available for the extraction and separation of natural plant flavors, each offering unique benefits that cater to the specific needs of different plant materials and desired outcomes.