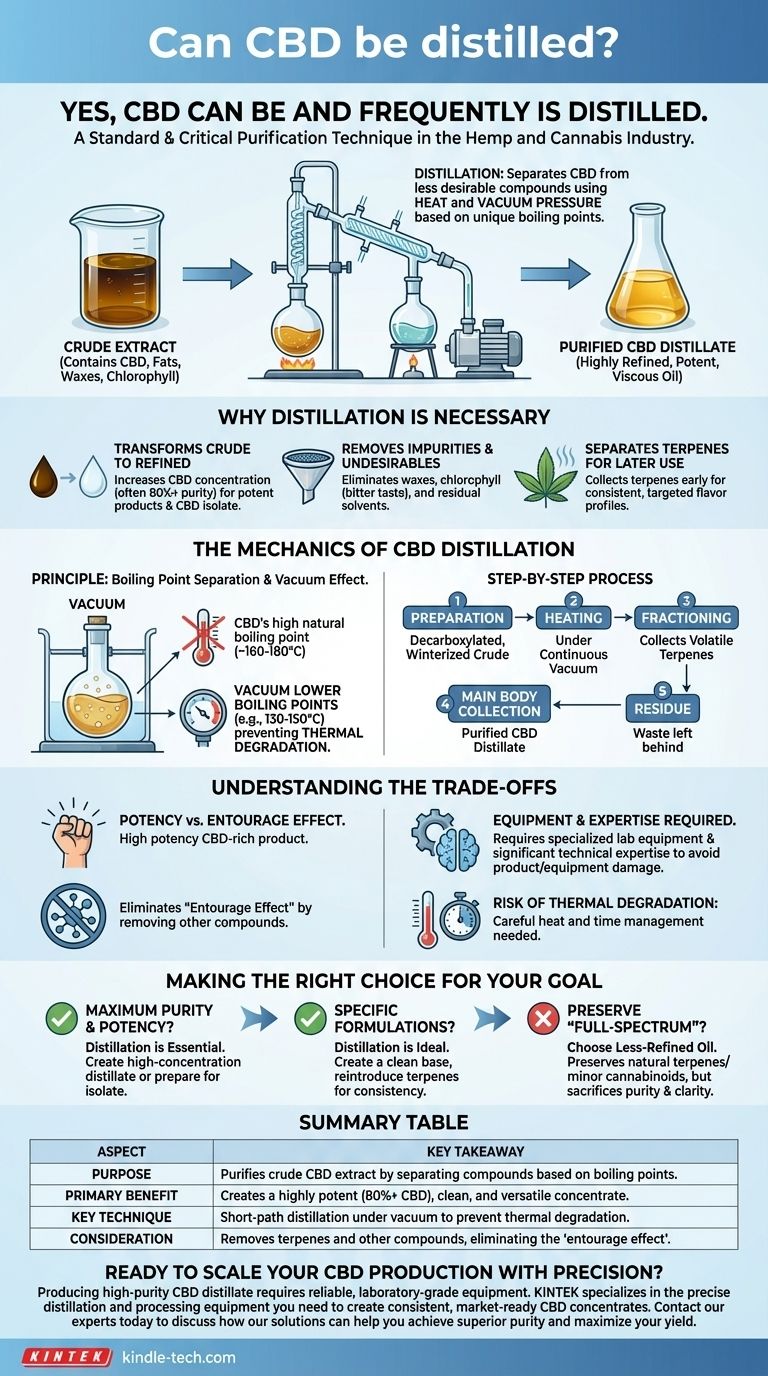

Yes, CBD can be and frequently is distilled. This process is a standard and critical purification technique in the hemp and cannabis industry. Distillation is used to separate CBD from other, less desirable compounds found in the initial crude extract, such as fats, waxes, chlorophyll, and other minor plant materials. The end result is a highly refined, potent, and viscous oil known as CBD distillate.

At its core, the challenge isn't just extracting CBD from the plant, but purifying it. Distillation solves this by using heat and vacuum pressure to selectively separate cannabinoids based on their unique boiling points, allowing manufacturers to isolate CBD and create a high-purity concentrate.

Why Distillation is Necessary for CBD Production

After initial extraction using methods like CO2 or ethanol, the resulting product is a dark, unrefined "crude oil." While rich in cannabinoids, it also contains many other plant compounds that affect its purity, taste, and appearance. Distillation is the key step to transform this crude oil into a refined, marketable product.

The Goal: From Crude Oil to Refined Concentrate

Crude hemp extract typically contains 60-70% CBD, along with a mix of lipids, chlorophyll, and other plant matter. Distillation significantly increases the concentration of CBD, often achieving purity levels of 80% or higher. This process is essential for creating potent products and serves as a prerequisite for producing CBD isolate.

Removing Impurities and Undesirable Compounds

The primary function of distillation is purification. It effectively removes unwanted compounds that were pulled from the plant during the initial extraction. This includes waxes that are harsh on the lungs, chlorophyll which imparts a bitter taste and dark color, and any potential residual solvents.

Separating Terpenes for Later Use

Terpenes, the aromatic compounds responsible for the plant's scent and flavor, have lower boiling points than cannabinoids. During the initial stages of distillation, these terpenes can be carefully collected. This allows producers to create a clean, neutral CBD distillate and then reintroduce specific terpenes later to craft products with consistent and targeted flavor profiles.

The Mechanics of CBD Distillation

The process hinges on a fundamental principle of chemistry: different substances vaporize at different temperatures. By precisely controlling heat and pressure, a skilled technician can isolate specific compounds, including CBD.

The Principle: Boiling Point Separation

Every compound in crude oil has a distinct boiling point. However, cannabinoids like CBD have very high boiling points (around 160-180°C or 320-356°F). Attempting to boil them at normal atmospheric pressure would require such high temperatures that it would destroy the molecules, a process known as thermal degradation.

Why a Vacuum is Essential: Short-Path Distillation

This is where vacuum comes in. By performing the distillation in a deep vacuum, the atmospheric pressure is dramatically lowered. This reduction in pressure also reduces the boiling point of all compounds, including CBD.

This technique allows the CBD to be vaporized at a much lower, safer temperature (e.g., 130-150°C), preserving its molecular integrity. The most common method used is short-path distillation, where the vapor only has to travel a short distance before it is cooled and re-condensed into a purified liquid.

The Step-by-Step Process

- Preparation: The process begins with winterized crude oil (where fats and waxes have already been removed through freezing) that has been decarboxylated to convert CBDA into active CBD.

- Heating: The prepared oil is placed into a heated flask under a continuous vacuum.

- Fractioning: As the temperature slowly rises, the most volatile compounds (like terpenes) vaporize first and are collected. This is the "heads" fraction.

- Main Body Collection: The temperature is then increased to the boiling point of CBD. The CBD-rich vapor rises, travels the "short path" to a chilled condensing surface, and turns back into a highly purified liquid oil. This is the "main body" or distillate.

- Residue: The remaining materials with higher boiling points, such as lipids and chlorophyll, are left behind in the boiling flask as waste.

Understanding the Trade-offs

While distillation is a powerful tool for purification, it is not without its considerations. The choice to distill depends entirely on the desired characteristics of the final product.

Potency vs. The Entourage Effect

Distillation creates a highly potent, CBD-rich product. However, by removing nearly all other compounds, it also eliminates the "entourage effect"—the theory that cannabinoids and terpenes work better together than they do in isolation. The resulting product is a broad-spectrum distillate (if THC is also removed) rather than a full-spectrum oil that retains the plant's original chemical profile.

Equipment and Expertise Required

This is not a simple process. Distillation requires expensive, specialized laboratory equipment, including glassware, heating mantles, and powerful vacuum pumps. More importantly, it demands significant technical expertise to operate safely and effectively, as improper temperature or vacuum control can ruin the product or damage the equipment.

The Risk of Thermal Degradation

Even under vacuum, there is a fine line between the temperature needed to vaporize CBD and the temperature that will degrade it. A skilled operator must carefully manage heat input and residence time to maximize yield and prevent the creation of unwanted byproducts like cannabinol (CBN) or other degradants.

Making the Right Choice for Your Goal

Deciding whether to use distillation comes down to your end goal. It is a tool for achieving a specific type of product with a defined set of characteristics.

- If your primary focus is maximum purity and potency: Distillation is an essential, non-negotiable step. It is the only way to create a high-concentration CBD distillate or to prepare the oil for further processing into 99%+ pure CBD isolate.

- If your primary focus is creating specific formulations: Distillation is ideal. It produces a clean, neutral, and potent base oil, allowing you to reintroduce specific terpenes or minor cannabinoids to craft highly consistent and tailored products.

- If your primary focus is preserving the "full-spectrum" plant profile: You may choose to use a less-refined, winterized oil. This preserves the natural terpenes and minor cannabinoids but sacrifices the purity, clarity, and high potency achieved through distillation.

Understanding the function and trade-offs of distillation empowers you to control the exact composition of any high-quality cannabinoid product.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Purpose | Purifies crude CBD extract by separating compounds based on boiling points. |

| Primary Benefit | Creates a highly potent (80%+ CBD), clean, and versatile concentrate. |

| Key Technique | Short-path distillation under vacuum to prevent thermal degradation. |

| Consideration | Removes terpenes and other compounds, eliminating the "entourage effect." |

Ready to Scale Your CBD Production with Precision?

Producing high-purity CBD distillate requires reliable, laboratory-grade equipment. KINTEK specializes in the precise distillation and processing equipment you need to create consistent, market-ready CBD concentrates.

Contact our experts today to discuss how our solutions can help you achieve superior purity and maximize your yield.

Visual Guide

Related Products

- Evaporation Crucible for Organic Matter

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Which solvent is normally used in IR spectroscopy? Optimize Your Sample Prep for Clearer Results

- Do cannabinoids evaporate? How to Preserve Potency and Prevent Degradation

- How long does it take for THC to evaporate? The Real Science Behind Potency Loss

- What precautions should be taken in a chemistry lab? Master the RAMP Framework for Ultimate Safety