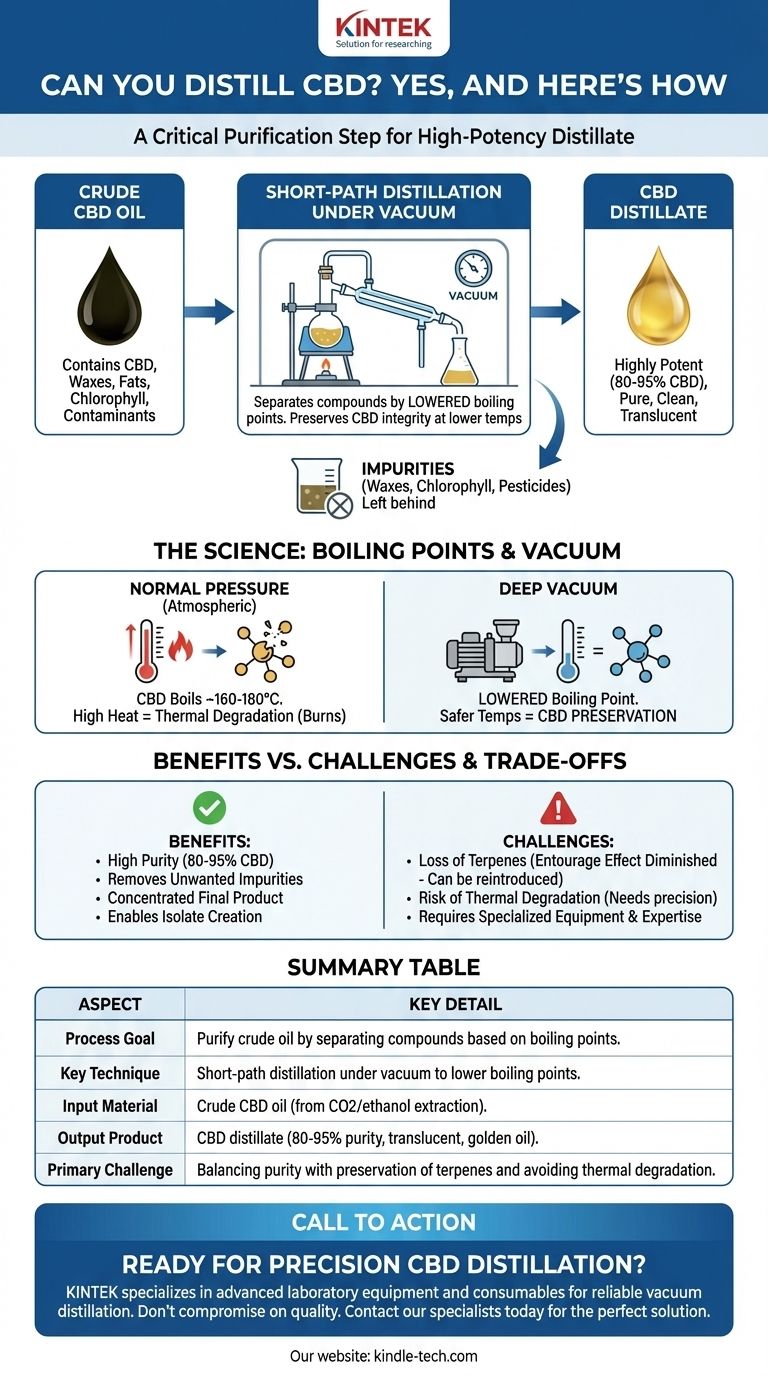

Yes, you can absolutely distill CBD. This process is a critical purification step used after the initial extraction of oil from the hemp or cannabis plant. Distillation separates CBD from other compounds like minor cannabinoids, terpenes, chlorophyll, and contaminants, resulting in a highly potent and pure liquid known as CBD distillate.

The core thing to understand is that distillation is not an extraction method; it is a refinement technique. It takes crude CBD oil and purifies it by leveraging the different boiling points of each compound, separating the desired CBD from everything else.

Why Distillation is Essential for High-Purity CBD

To appreciate the role of distillation, you must first understand the material it starts with: crude oil.

From Crude Oil to Refined Product

Initial extraction methods, such as CO2 or ethanol extraction, pull a wide range of compounds from the plant material. The result is a dark, thick, unrefined substance called crude CBD oil, which contains CBD but also waxes, fats, lipids, and other plant matter.

The Goal: Isolation Through Volatility

The fundamental goal of distillation is to isolate specific compounds based on their boiling points. Each molecule in the crude oil, from CBD and THC to terpenes and chlorophyll, turns into a vapor at a different temperature. By precisely controlling heat and pressure, a skilled technician can separate these compounds one by one.

Removing Unwanted Impurities

This process is exceptionally effective at removing undesirable elements. Waxes, chlorophyll, pesticides, and other contaminants have very different boiling points than cannabinoids. Distillation leaves these impurities behind, resulting in a cleaner, safer, and more concentrated final product.

The Science of CBD Distillation

The high boiling points of cannabinoids make this a specialized process that requires specific laboratory equipment and a deep understanding of chemistry.

The Principle of Boiling Points

At normal atmospheric pressure, cannabinoids have extremely high boiling points (CBD boils around 160-180°C or 320-356°F). Heating crude oil to these temperatures would simply burn and destroy the valuable compounds.

The Critical Role of Vacuum

To avoid destroying the CBD, the entire process is performed under a deep vacuum. A vacuum dramatically lowers the pressure inside the system, which in turn lowers the boiling point of every compound. This allows the CBD to vaporize at a much lower, safer temperature, preserving its integrity.

Common Technique: Short-Path Distillation

The most common method used is short-path distillation. In this setup, the heated crude oil releases vapor that travels a very short distance—the "short path"—to a condensing surface. The pure CBD vapor cools, turns back into a liquid, and is collected. Heavier, less volatile materials like waxes and lipids are left behind in the original flask.

The End Product: CBD Distillate

The result of this process is CBD distillate, a thick, translucent oil that is typically light amber or golden in color. It is highly potent, often containing 80-95% pure CBD, with the remaining percentage consisting of other minor cannabinoids and terpenes.

Understanding the Trade-offs and Challenges

While distillation is powerful, it is not without its complexities and compromises. Understanding these is key to producing a high-quality product.

Loss of Terpenes and the "Entourage Effect"

Terpenes, the aromatic compounds responsible for the plant's scent and flavor, are very volatile and are often lost during the high-heat distillation process. This can diminish the "entourage effect," where multiple cannabis compounds work together synergistically. Many producers collect these terpenes separately and reintroduce them into the final product.

Significant Equipment and Expertise Required

This is not a simple DIY process. It requires expensive, specialized laboratory equipment, including glassware, heating mantles, and powerful vacuum pumps. More importantly, it demands a high level of technical skill to operate safely and effectively, as improper temperature or vacuum control can ruin the entire batch.

Risk of Thermal Degradation

Even under vacuum, there is still a risk of damaging the cannabinoids if the temperature is not managed with precision. An unskilled operator can easily "cook" the oil, degrading the CBD and creating unwanted byproducts.

Making the Right Choice for Your Goal

The decision to use distillation and how to approach it depends entirely on the desired characteristics of your final product.

- If your primary focus is creating a full-spectrum product: You might use distillation to clean up the crude oil but take special care to preserve or reintroduce terpenes to maintain the "entourage effect."

- If your primary focus is maximizing CBD potency and purity: Distillation is the essential, non-negotiable step to produce the high-concentration distillate required for vape cartridges, edibles, or as a precursor for creating CBD isolate.

- If your primary focus is guaranteed THC removal: Fractional distillation, a more precise form of the process, is the key industrial method for separating and removing THC to create compliant, broad-spectrum products.

Ultimately, mastering distillation provides complete control over the chemical profile, purity, and quality of the final CBD product.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Goal | Purify crude CBD oil by separating compounds based on boiling points. |

| Key Technique | Short-path distillation under vacuum to lower boiling points. |

| Input Material | Crude CBD oil (from CO2/ethanol extraction). |

| Output Product | CBD distillate (80-95% purity, translucent, golden oil). |

| Primary Challenge | Balancing purity with preservation of terpenes and avoiding thermal degradation. |

Ready to produce high-purity CBD distillate with precision and reliability? The distillation process demands expert control and professional-grade equipment to avoid thermal degradation and ensure consistent results. KINTEK specializes in advanced laboratory equipment and consumables for the cannabis and hemp industry, providing the reliable vacuum distillation systems and expert support you need to scale your production. Don't let equipment limitations compromise your product quality—contact our specialists today to find the perfect solution for your lab's purification goals.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Graphite Vacuum Continuous Graphitization Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- Why must Ni–20Cr–5Al alloy samples be dried in a laboratory oven? Ensure 0.0001g Precision in Corrosion Experiments

- What temperature range do Ultra-Low Temperature (ULT) freezers typically maintain? Preserve Your Samples from -40°C to -86°C

- What advantages do ultra-low temperature freezers offer? Ensure Long-Term Sample Integrity and Reliability

- Is sintering the same as welding? Key Differences in Material Bonding and Fusion Explained

- What is the minimum coating thickness? How Steel Thickness Determines Your Galvanizing Needs

- What are the 2 main materials used in selective laser sintering process? Polymers vs. Metals for Your 3D Printing Needs

- Does heat treatment increase strength? Unlock Maximum Metal Performance for Your Components

- How does a water bath work? Master Precise and Gentle Heating for Your Lab