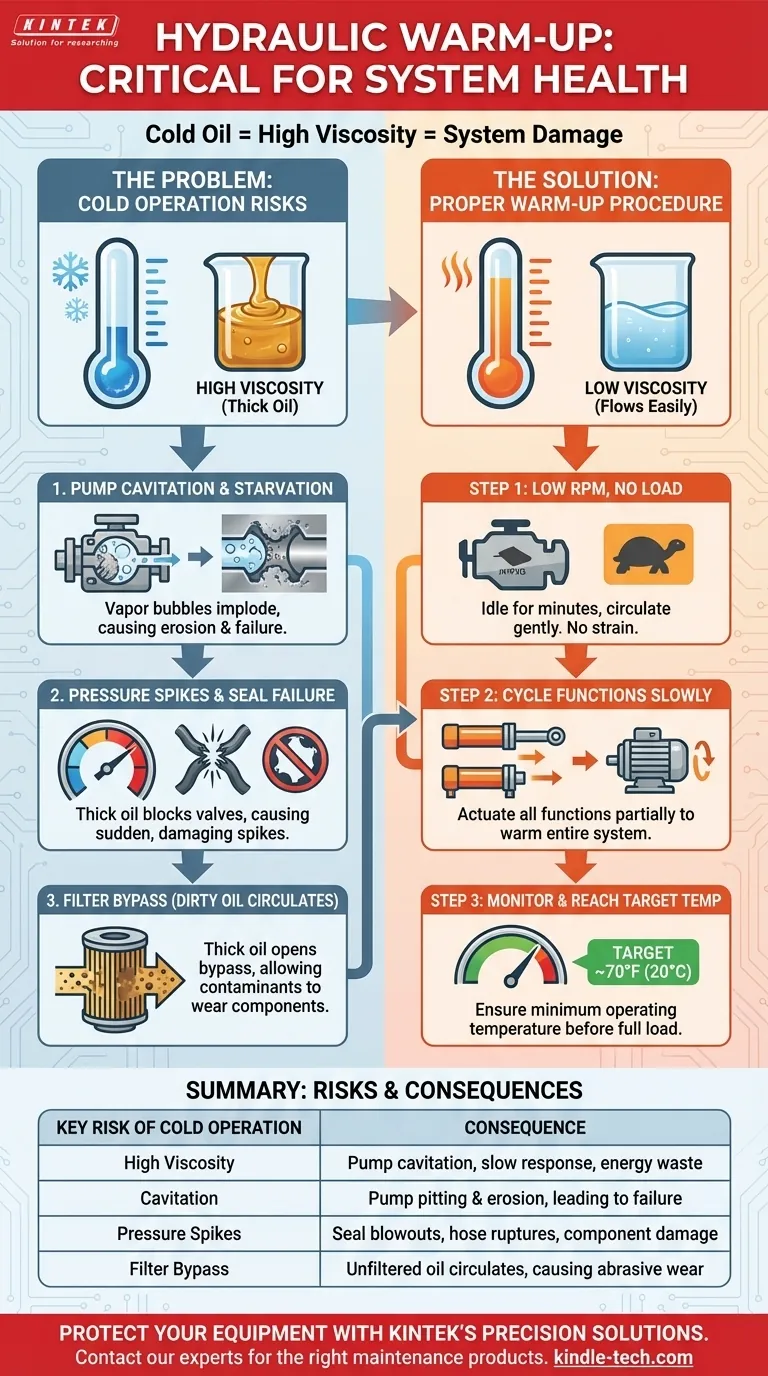

Yes, warming up a hydraulic system is not just recommended; it is critical for its health and performance. Operating hydraulic equipment with cold fluid forces thick, slow-moving oil through the system, which can starve the pump, cause pressure spikes, and lead to premature component failure. A deliberate warm-up procedure is a fundamental part of preventive maintenance that protects your investment.

The core issue with cold hydraulic fluid is its high viscosity. Attempting to run a system at full power with cold, honey-like fluid is like asking an athlete to sprint without a warm-up—it invites damage, specifically by causing pump cavitation and placing extreme stress on seals and hoses.

The Physics of Cold Hydraulic Fluid

To understand the need for a warm-up, we must first understand how temperature fundamentally changes the behavior of hydraulic oil.

Viscosity: The Heart of the Matter

Viscosity is a fluid's resistance to flow. When hydraulic oil is cold, its viscosity is high, meaning it is thick and flows poorly. As the system runs and the oil heats up, its viscosity drops, allowing it to flow easily.

Think of the difference between pouring cold honey and pouring warm water. Your hydraulic pump has to work much harder to pull in and push out that thick, cold "honey."

The Danger of Cavitation

Cavitation is the single most destructive risk of a cold start. Because the thick oil cannot flow into the pump's inlet fast enough to fill the void, a partial vacuum is created. This causes vapor bubbles to form within the fluid.

As these bubbles travel to the high-pressure side of the pump, they violently collapse. This collapse creates a micro-jet of fluid that blasts the pump's internal metal surfaces, causing pitting and erosion that will quickly destroy it.

Sluggish Response and Inefficiency

When oil is too viscous, it struggles to move through tight tolerances in valves, hoses, and cylinders. This results in slow and jerky actuator movement, making precise control impossible.

Furthermore, the prime mover (engine or electric motor) must expend significant extra energy just to circulate the thick fluid. This wastes fuel and puts unnecessary strain on the entire power unit.

How Cold Operation Damages Your Equipment

Ignoring a warm-up routine doesn't just reduce performance; it actively damages expensive components.

Starving the Hydraulic Pump

Cavitation is, in effect, starving the pump of fluid. The pump is the heart of your hydraulic system and often its most expensive component. Running it without a sufficient supply of oil, even for a few minutes at a time, dramatically shortens its service life.

Pressure Spikes and Seal Failure

Cold, thick fluid does not flow easily through pressure relief valves, which are designed to protect the system from over-pressurization. A sudden blockage or a quickly actuated function can cause a massive pressure spike that the valve cannot react to in time.

These spikes can blow out hydraulic seals, rupture hoses, and even crack component housings, leading to major leaks and costly downtime.

Bypassing Your Filtration

Most hydraulic filters have a bypass valve that opens if the filter element becomes clogged. However, cold, thick oil can create enough backpressure to open this valve even when the filter is clean.

When this happens, unfiltered oil bypasses the filter entirely. Any contaminants in the system are then free to circulate and cause abrasive wear on precision-machined surfaces in your pumps, valves, and motors.

The Proper Warm-up Procedure

A correct warm-up is simple and requires only a few minutes of patience.

Start with Low RPM and No Load

Begin by starting the engine or motor at a low idle. Let it run for several minutes with all hydraulic controls in neutral. This allows the pump to circulate the oil gently through the main circuit and reservoir, beginning the warming process without putting the system under strain.

Cycle Functions Slowly and Partially

After the initial period, begin to slowly and partially actuate all hydraulic functions. For example, raise and lower a boom, extend and retract a cylinder, or turn a hydraulic motor back and forth.

Do this without any load on the machine. This step is crucial because it pushes the warming fluid out into the actuators and hoses, ensuring the entire system reaches a uniform temperature.

Monitor System Gauges

The goal is to bring the hydraulic fluid up to its minimum recommended operating temperature, which is typically specified in the equipment's operator manual. While this varies, a general target is often around 70°F (20°C). Once the system is warm, you can begin to operate it under normal loads.

Making the Right Choice for Your Goal

Adopting a proper warm-up strategy is a choice between short-term haste and long-term reliability.

- If your primary focus is equipment longevity and minimizing costs: Always perform a full warm-up by cycling all functions at low speed until the minimum operating temperature is reached.

- If you operate in extremely cold climates (sub-zero): Consider installing a hydraulic tank heater and using a high-quality, synthetic multigrade fluid to shorten warm-up times and provide superior protection.

- If you are facing an emergency and must operate immediately: Run the equipment at the lowest possible engine RPM and load, understanding that this will cause accelerated wear and increase the risk of component failure.

Treating a hydraulic warm-up as a mandatory operational step is the single most effective way to protect your investment and ensure reliable performance.

Summary Table:

| Key Risk of Cold Operation | Consequence |

|---|---|

| High Viscosity (Thick Oil) | Pump cavitation, slow response, energy waste |

| Cavitation | Pump pitting and erosion, leading to failure |

| Pressure Spikes | Seal blowouts, hose ruptures, component damage |

| Filter Bypass | Unfiltered oil circulates, causing abrasive wear |

Protect your hydraulic equipment with KINTEK's precision lab solutions. Proper maintenance starts with the right tools and consumables. Whether you're managing industrial machinery or laboratory hydraulic systems, KINTEK specializes in durable equipment and high-quality fluids designed for optimal performance and longevity. Contact our experts today to find the perfect hydraulic maintenance products for your needs and avoid costly downtime.

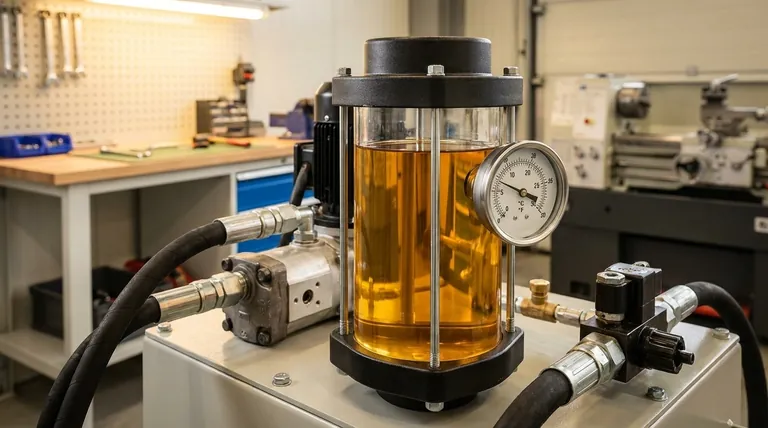

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the causes of heat generation in hydraulic systems? Uncover the Key Sources of Energy Loss

- What is the role of a laboratory hydraulic press in the initial stages of Li6PS5Cl preparation? Key to Green Pellets

- How do I choose a press? A Guide to Matching Your Specific Operational Needs

- What is the difference between a pneumatic press machine and a hydraulic press machine? Choose the Right Press for Your Job

- Which is better EDX or XRF? Choose the Right Elemental Analysis Tool for Your Needs

- How to prepare samples for XRF? Achieve Accurate and Repeatable Elemental Analysis

- What is the maximum psi for a hydraulic press? Understand Tonnage, Not Just Pressure

- Why is graphite powder used in Cu-Al2O3 compression tests? Ensure Accurate Flow Stress and Uniform Deformation