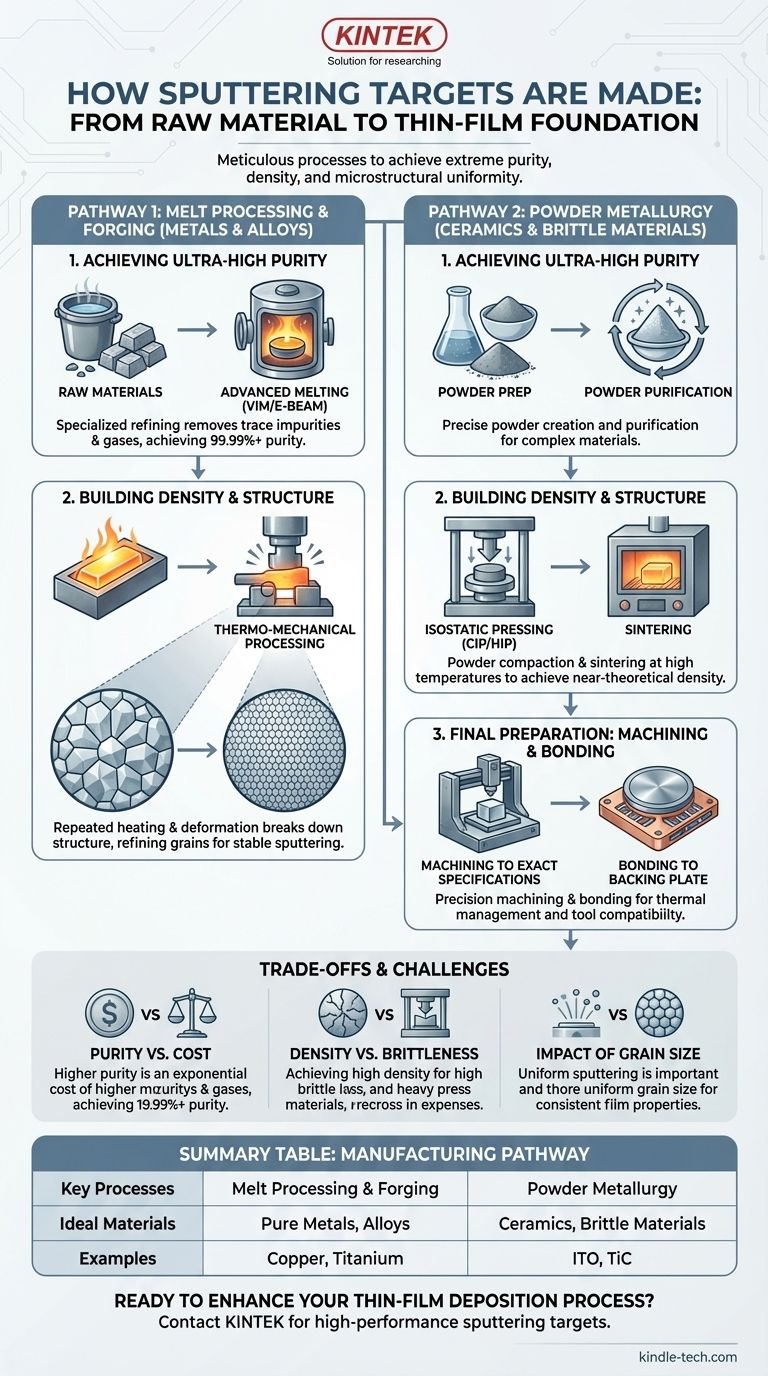

In short, sputtering targets are manufactured using one of two main pathways: melt processing for metals and alloys, or powder metallurgy for ceramics and complex materials. Both methods are meticulously controlled to achieve the extreme purity, density, and microstructural uniformity required for high-performance thin-film deposition.

The production of a sputtering target is not merely fabrication; it is a multi-stage refinement process. The core challenge is to systematically remove impurities and eliminate internal defects, as the atomic-level quality of the target directly dictates the performance and consistency of the final coating.

The Foundation: Achieving Ultra-High Purity

The quality of any thin film begins with the purity of its source material. For sputtering targets, this requirement is non-negotiable, as even trace impurities in the target can become incorporated into the film, degrading its electrical, optical, or mechanical properties.

### Starting with Raw Materials

The process begins with the selection and purification of raw materials. Standard commercial-grade metals or compounds are rarely sufficient. Specialized refining techniques are used to remove unwanted elements and dissolved gases, often achieving purity levels of 99.99% (4N) to 99.9999% (6N).

### The Role of Advanced Melting

For metallic targets, techniques like Vacuum Induction Melting (VIM) or Electron Beam Melting are often employed. Melting the material in a high vacuum removes volatile impurities and dissolved gases like oxygen and nitrogen, which would otherwise lead to defects in the deposited film.

Building Density and Structure: The Two Core Pathways

Once a pure ingot or powder is created, it must be consolidated into a dense, solid block with a fine, uniform grain structure. The choice of method depends almost entirely on the material's properties.

### Pathway 1: Melt Processing & Forging (For Metals & Alloys)

This is the most common route for pure metals and many alloys. The purified material is cast into a solid ingot, which is then subjected to a series of thermo-mechanical processes.

This involves repeated cycles of heating and mechanical deformation, such as forging or rolling. This critical step breaks down the large, inconsistent crystal structure of the cast ingot, refining it into the fine, uniform grains essential for a stable and uniform sputtering rate. It also helps close any internal voids or porosity.

### Pathway 2: Powder Metallurgy (For Ceramics & Brittle Materials)

Materials like ceramics (e.g., Indium Tin Oxide, ITO) or certain complex alloys cannot be easily melted and cast. For these, powder metallurgy is the solution.

The process involves creating a fine powder of the material, pressing it into the desired shape, and heating it to a temperature just below its melting point in a process called sintering.

Techniques like Cold Isostatic Pressing (CIP) or Hot Isostatic Pressing (HIP) are used to compact the powder under immense pressure. HIP is particularly effective as it combines high temperature and pressure simultaneously, producing targets with a density that can exceed 95% of the theoretical maximum.

Final Preparation: Machining and Bonding

The consolidated, high-density material is still just a rough block. The final steps convert it into a finished, usable component for a sputtering system.

### Machining to Exact Specifications

The block is precisely machined to the final dimensions required by the sputtering tool. This could be a flat disc, a rectangular plate, or a more complex shape like a cylinder or ring. High surface flatness and a smooth finish are critical to ensure uniform plasma erosion and thermal contact.

### Bonding to the Backing Plate

Sputtering is a high-energy process that generates significant heat. To manage this, the target material is bonded to a backing plate (or "holder"), typically made of copper or aluminum. This plate provides structural support and incorporates cooling channels for water circulation, preventing the target from overheating and cracking during use.

Understanding the Trade-offs and Challenges

The ideal sputtering target is perfectly pure, fully dense, and has a uniform microstructure, but achieving this involves navigating key technical and economic trade-offs.

### Purity vs. Cost

Each additional "nine" in purity (e.g., from 99.99% to 99.999%) can increase the cost of the target exponentially due to the advanced refining techniques required. For many applications, a 4N target is sufficient, while cutting-edge semiconductor processes may demand 6N or higher.

### Density vs. Material Brittleness

Achieving near-theoretical density is crucial for minimizing arcing and particle generation during sputtering. While HIP is excellent for density, it is an expensive process. For brittle ceramics, preventing cracks and ensuring structural integrity during pressing and sintering is a major manufacturing challenge.

### The Impact of Grain Size

A target with large or non-uniform grains will sputter at an inconsistent rate, leading to a film with uneven thickness and properties. The extensive thermo-mechanical work needed to create a fine, uniform grain structure is a primary factor that separates a high-quality target from a mediocre one.

Connecting Manufacturing to Your Application

The method used to create a target directly impacts its performance in your process. Understanding this link allows you to select the right product and troubleshoot more effectively.

- If your primary focus is process stability and repeatability: Prioritize targets with certified small, uniform grain size and high density, which are products of extensive thermo-mechanical work or Hot Isostatic Pressing (HIP).

- If your primary focus is film purity for sensitive electronics: Demand targets with the highest available purity (e.g., 5N or 6N), which requires advanced refining methods like electron beam melting during manufacturing.

- If you are working with complex ceramics (like ITO or TiC): Your targets are made via powder metallurgy; focus on suppliers who can prove high density (>95% theoretical) and compositional uniformity to minimize film defects.

Knowing how a sputtering target is made gives you the insight needed to select the right material and diagnose critical issues in your deposition process.

Summary Table:

| Manufacturing Pathway | Key Processes | Ideal Materials |

|---|---|---|

| Melt Processing & Forging | Vacuum Induction Melting (VIM), Forging, Rolling | Pure Metals, Alloys (e.g., Copper, Titanium) |

| Powder Metallurgy | Cold/Hot Isostatic Pressing (CIP/HIP), Sintering | Ceramics, Brittle Materials (e.g., ITO, TiC) |

Ready to Enhance Your Thin-Film Deposition Process?

The quality of your sputtering target is the foundation of your coating's performance. KINTEK specializes in providing high-performance lab equipment and consumables, including precisely manufactured sputtering targets for all your laboratory needs.

Let our expertise guide you to the right solution for superior film purity, density, and process stability. Contact KINTEK today to discuss your specific application requirements.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- How thick is the thin film color? Unlocking the Nanometer Scale of Iridescent Effects

- What are the applications of carbon nanomaterials? Unlock Revolutionary Performance in Energy, Materials & Electronics

- What is the effect of temperature on graphene oxide? Master Thermal Reduction for Precise Material Properties

- What are carbon nanotubes advantages and disadvantages? Balancing Performance and Practicality

- Why are carbon nanotubes bad for the environment? Understanding the Toxicity vs. Performance Trade-Offs

- What are the key properties of Silver (Ag)? Discover the Element with Unmatched Electrical and Thermal Conductivity

- What are the uses of thin films? Unlock New Surface Properties for Your Materials

- Is deposition a chemical process? Understanding Chemical vs. Physical Thin-Film Methods