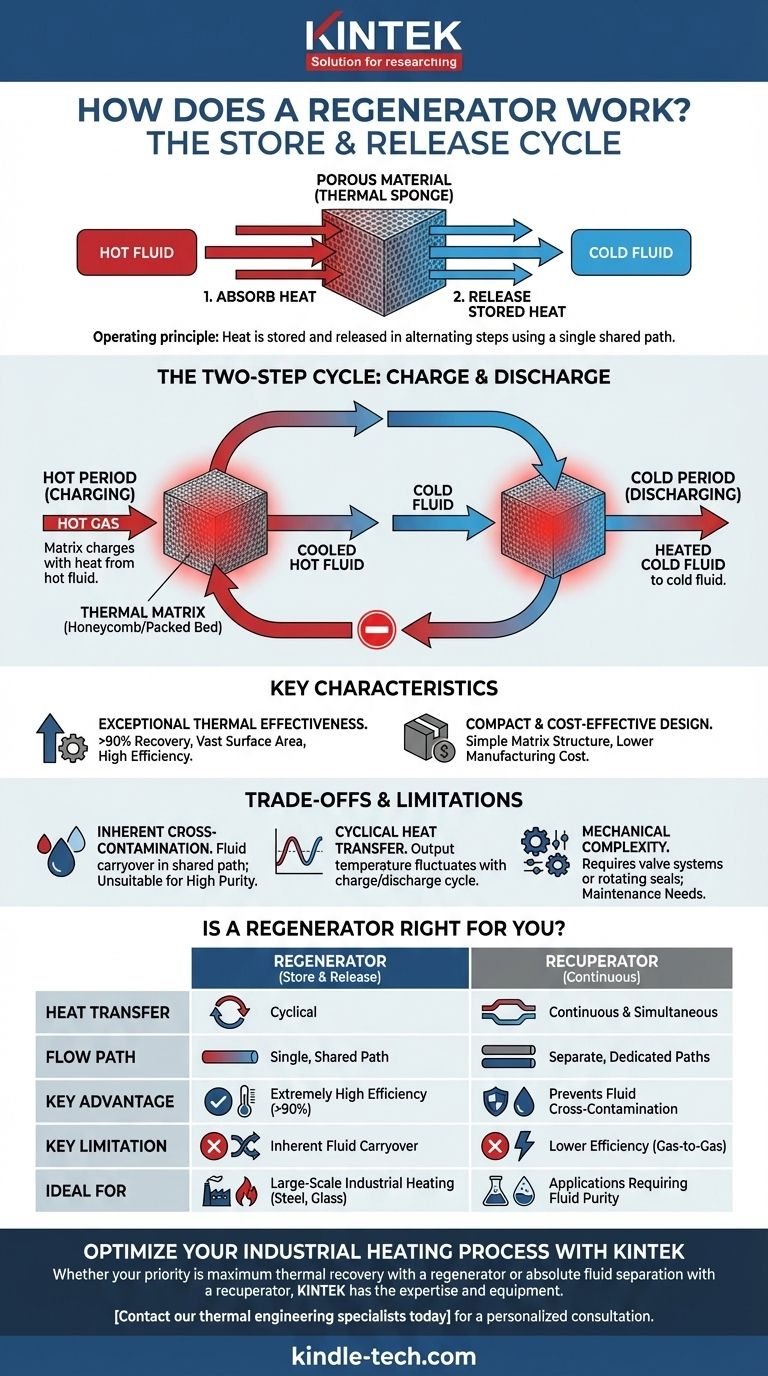

At its core, a regenerator works by first absorbing heat from a hot fluid into a porous material, and then releasing that stored heat to a colder fluid in a separate, alternating step. Unlike a common radiator where two fluids exchange heat simultaneously, a regenerator operates in a two-stage cycle of storing and releasing thermal energy.

The defining principle of a regenerator is its use of a single, shared path for both hot and cold fluids, separated by time. This allows for extremely high thermal efficiency but introduces inherent cross-contamination as a fundamental trade-off.

The Two-Step Cycle: Store and Release

A regenerator's operation is defined by its cyclical nature. It doesn't transfer heat directly between fluids but uses an intermediary storage medium, known as the matrix.

The Hot Period (Charging the Matrix)

First, a hot gas or liquid flows through the channels of the regenerator. As it passes, it transfers its thermal energy to the internal matrix material, which heats up significantly. The now-cooler hot fluid then exits the system. This step is essentially "charging" the matrix with heat.

The Cold Period (Discharging the Matrix)

Next, the flow of the hot fluid is stopped. The flow path is switched, and a separate, colder fluid is directed through the same hot matrix. As the cold fluid passes, it absorbs the stored heat from the matrix, exiting the system at a much higher temperature. This "discharges" the matrix, cooling it down and preparing it for the next hot period.

The Role of the Thermal Matrix

The matrix is the heart of the regenerator. It is a solid material with a high heat capacity and a very large surface area, often configured as a honeycomb, mesh, or a bed of packed particles. Materials like ceramics or metals are common choices. Its job is simply to act as a temporary thermal sponge: soaking up heat efficiently and then releasing it just as efficiently.

Key Characteristics of Regenerators

The unique cyclical design gives regenerators distinct advantages in specific applications, primarily driven by efficiency and physical design.

Exceptional Thermal Effectiveness

Regenerators can achieve extremely high rates of thermal recovery, often exceeding 90%. Because the heat transfer surface is the entire mass of the matrix, they offer a vast surface area in a relatively small volume, enabling more complete heat transfer than many other designs.

Compact and Cost-Effective Design

The simple structure of a matrix—like a ceramic honeycomb or a bed of metal spheres—is often less complex and cheaper to manufacture than the intricate tubes, fins, and plates of other heat exchanger types. This makes them a cost-effective solution for large-scale industrial processes.

Understanding the Trade-offs and Limitations

The primary strength of a regenerator—its use of a single flow path—is also the source of its biggest weakness.

Inherent Cross-Contamination

Because both hot and cold fluids pass through the same matrix, a small amount of the fluid from the first step (the "carryover") will inevitably mix with the fluid in the second step. This makes regenerators entirely unsuitable for applications where fluid purity is critical, such as in food processing or high-purity chemical systems.

Cyclical, Not Continuous, Heat Transfer

The heat transfer process is not steady-state. As the matrix gives up its heat during the cold period, its temperature drops, causing the outlet temperature of the heated fluid to fluctuate slightly over the course of the cycle. In applications requiring a perfectly stable output temperature, this can be a drawback.

Mechanical Complexity

To manage the alternating flows, regenerators require either complex valve systems (for fixed-bed regenerators) or large, rotating seals (for rotary regenerators). These moving parts add mechanical complexity and introduce potential points of failure and maintenance.

Is a Regenerator Right for Your Application?

Choosing between a regenerator and a different type of heat exchanger (known as a recuperator) comes down to balancing efficiency against purity.

- If your primary focus is maximum thermal efficiency and compactness: A regenerator is often the superior choice, especially for gas-to-gas heat recovery in large industrial plants like steel mills or glass furnaces where some cross-mixing is acceptable.

- If your primary focus is preventing any mixing of fluids: You must use a recuperative exchanger (like a shell-and-tube or plate-and-frame), as the carryover contamination in a regenerator is unavoidable.

- If your primary focus is a perfectly stable output temperature: A recuperator provides a more consistent output, as its steady-state operation avoids the temperature swings inherent in a regenerator's charge-discharge cycle.

Understanding this fundamental store-and-release principle empowers you to select the right heat exchange technology for your specific engineering goals.

Summary Table:

| Feature | Regenerator | Recuperator |

|---|---|---|

| Heat Transfer Method | Cyclical (store & release) | Continuous & simultaneous |

| Flow Path | Single, shared path | Separate, dedicated paths |

| Key Advantage | Extremely high thermal efficiency (>90%) | Prevents fluid cross-contamination |

| Key Limitation | Inherent fluid carryover/mixing | Lower efficiency for gas-to-gas |

| Ideal For | Large-scale industrial heating (e.g., steel, glass) | Applications requiring fluid purity |

Optimize Your Industrial Heating Process with KINTEK

Understanding the right heat exchange technology is critical for your operation's efficiency and product purity. Whether your priority is maximum thermal recovery with a regenerator or absolute fluid separation with a recuperator, KINTEK has the expertise and equipment to meet your specific laboratory and industrial needs.

We specialize in providing robust, high-performance lab equipment and consumables tailored for demanding environments. Let our experts help you select the perfect solution to enhance your process efficiency and reduce operational costs.

Contact our thermal engineering specialists today for a personalized consultation.

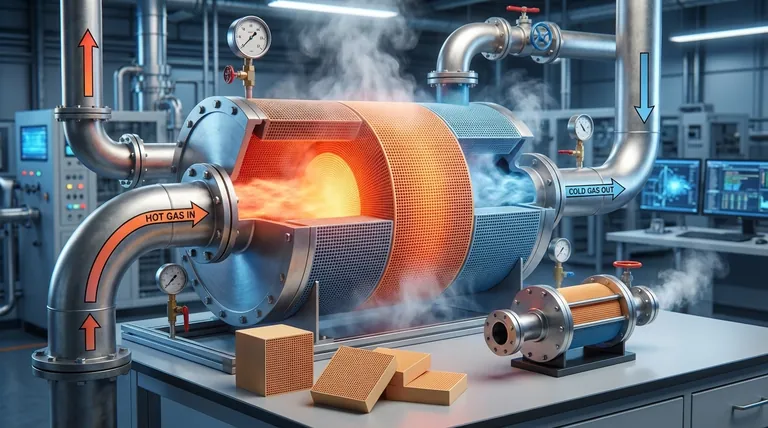

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- Why is a vacuum oven necessary for CSD tungsten coatings? Ensure Precise Evaporation and Coating Integrity

- Which heat transfer can travel through the vacuum of space? Thermal Radiation Powers the Cosmos

- What is a drop bottom furnace? Achieve Superior Uniform Heating for Heavy & Delicate Parts

- What are the different annealing techniques? A Guide to Softening, Stress Relief, and Machinability

- Which machine is used for sintering? Choose the Right Furnace for Your Materials

- What is the brazing process in short note? Master the Key Parameters for Strong Metal Joints

- What is the traditional sintering process? A Guide to Powder Metallurgy & Ceramic Fabrication

- How does a sintering furnace influence EDC powder metallurgy electrodes? Optimize Your Tool for Superior Coatings