At its core, CBD oil is distilled using heat and vacuum pressure to purify it. This process, known as short-path distillation, works by separating compounds based on their unique boiling points. It effectively transforms a raw, unrefined CBD extract into a highly potent, golden-amber concentrate by removing undesirable components like waxes, chlorophyll, and other plant materials.

The crucial takeaway is that distillation is not the initial extraction of CBD from the plant; it is the critical refinement step that determines the final product's purity, potency, and clarity. It separates the desired cannabinoids from virtually everything else.

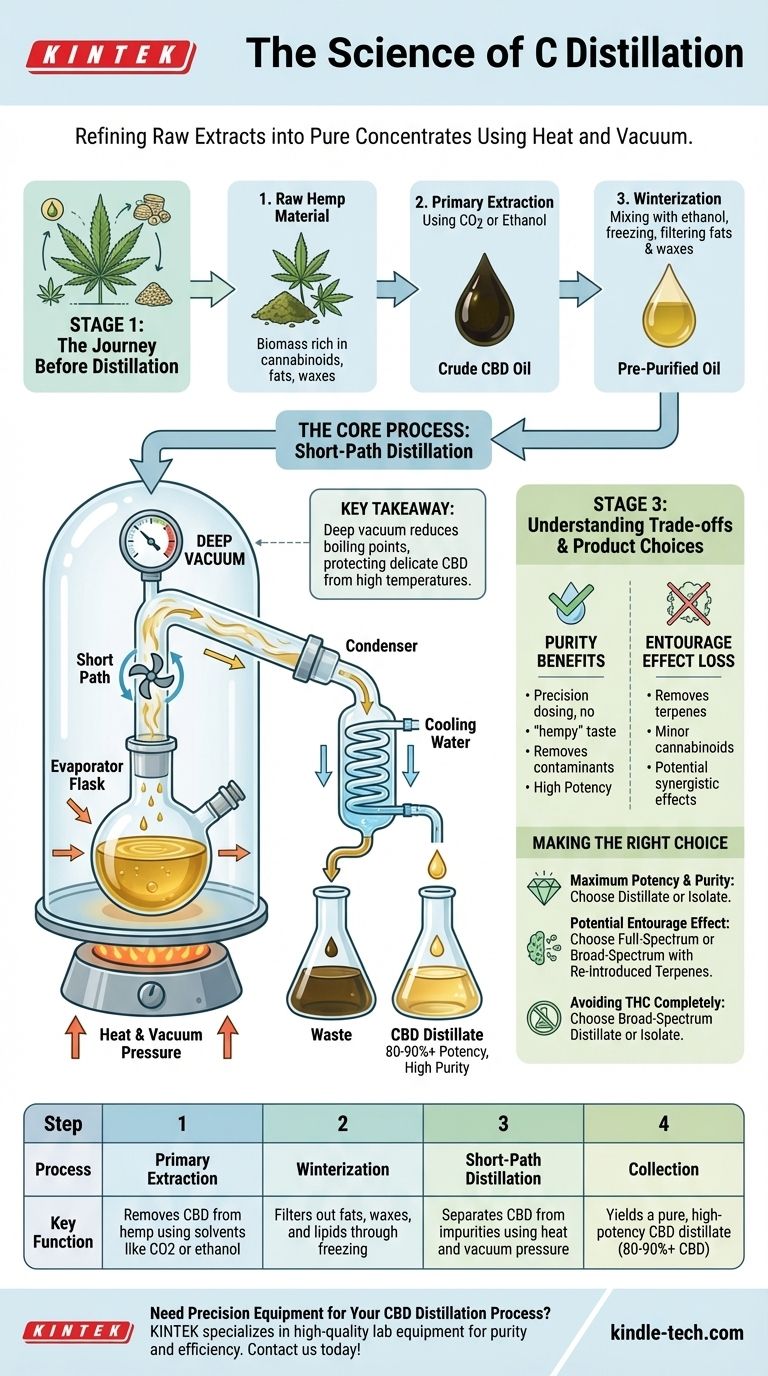

The Journey Before Distillation: From Plant to Crude Oil

Distillation is a key step, but it doesn't happen first. To understand the process, you must first understand what is being distilled: a crude oil extract that has already been pulled from the hemp plant.

The Starting Point: Raw Hemp Material

The process begins with high-quality hemp biomass, which is rich in cannabinoids like CBD but also contains fats, waxes, chlorophyll, and terpenes.

Step 1: Primary Extraction

First, the CBD must be removed from the plant material. This is typically done using a solvent like supercritical CO2 or ethanol. The result of this initial step is a dark, thick, unrefined substance known as crude CBD oil.

Step 2: Winterization

This crude oil is then mixed with ethanol and frozen. This process, called winterization, causes fats, lipids, and waxes to solidify and precipitate. These solids are then filtered out, leaving a more refined oil.

The Result: A Pre-Purified Oil Ready for Distillation

After extraction and winterization, we have an oil that is rich in cannabinoids but still contains smaller impurities, including terpenes, flavonoids, and residual contaminants. This is the material that is fed into the distillation system.

The Core of the Process: Short-Path Distillation

This is where the true purification happens. The goal is to isolate the CBD molecule from everything else by taking advantage of its specific boiling point.

The Principle: Separating by Boiling Point

Every compound vaporizes at a specific temperature. The distillation apparatus heats the crude oil, causing different compounds to turn into vapor at different temperatures. This vapor is then cooled and collected, effectively separating the desired compounds.

The Challenge: High Temperatures Degrade CBD

Cannabinoids are delicate. The temperature required to vaporize CBD at normal atmospheric pressure is high enough to degrade or destroy it. This is the central problem that the entire system is designed to solve.

The Solution: Using a Deep Vacuum

The solution is to perform the distillation under a deep vacuum. Lowering the pressure inside the system drastically reduces the boiling point of all compounds, including CBD. This allows vaporization to occur at a much lower, safer temperature, preserving the integrity of the molecule.

The Equipment: A Walkthrough

A short-path distillation system involves a heated flask (the evaporator), a rotating wiper that spreads a thin film of oil on the heated surface, a condenser, and separate collection flasks for waste and the final product. As the cannabinoids vaporize, they travel a very "short path" to the condenser, where they turn back into a liquid and are collected as pure CBD distillate.

Understanding the Trade-offs: Purity vs. The Entourage Effect

Distillation is incredibly effective at creating a pure, high-potency product. However, this level of refinement involves clear trade-offs that are important to understand.

The Benefit of Purity: Potency and Consistency

A CBD distillate is highly concentrated, often reaching 80-90%+ CBD. This purity allows for precise, consistent dosing and removes the "hempy" taste and dark color associated with crude oils. It also ensures the removal of any potential contaminants.

The Downside: Loss of the "Full Spectrum"

The distillation process also removes most of the plant's other beneficial compounds, particularly terpenes (which contribute to aroma and effect) and minor cannabinoids. This strips away the potential for the "entourage effect," a theory suggesting that cannabinoids work better together than they do in isolation.

The Industry Solution: Broad-Spectrum and Re-Introduced Terpenes

To address this, producers can create broad-spectrum products. They start with a pure CBD distillate (which has also had all THC removed) and then re-introduce specific terpenes and minor cannabinoids. This offers a middle ground between a pure isolate and a full-spectrum extract.

Making the Right Choice for Your Goal

Understanding how distillation works allows you to select a product based on its chemical makeup rather than just its marketing.

- If your primary focus is maximum potency and flavorless purity: Choose products made from CBD distillate or a further refined CBD isolate.

- If your primary focus is the potential "entourage effect": Look for less-refined full-spectrum products or broad-spectrum distillates where specific terpenes have been added back.

- If your primary focus is avoiding THC completely: A broad-spectrum distillate or a CBD isolate are the most reliable choices, as the distillation process is excellent at removing THC.

By understanding the role of distillation, you can now look beyond the label and choose a product based on its fundamental composition.

Summary Table:

| Step | Process | Key Function |

|---|---|---|

| 1 | Primary Extraction | Removes CBD from hemp using solvents like CO2 or ethanol |

| 2 | Winterization | Filters out fats, waxes, and lipids through freezing |

| 3 | Short-Path Distillation | Separates CBD from impurities using heat and vacuum pressure |

| 4 | Collection | Yields a pure, high-potency CBD distillate (80-90%+ CBD) |

Need Precision Equipment for Your CBD Distillation Process? KINTEK specializes in high-quality lab equipment and consumables for laboratories focused on purity and efficiency. Whether you're scaling production or refining your extraction methods, our reliable systems ensure consistent results. Contact us today to discuss how we can support your lab's specific needs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High Performance Laboratory Freeze Dryer

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating