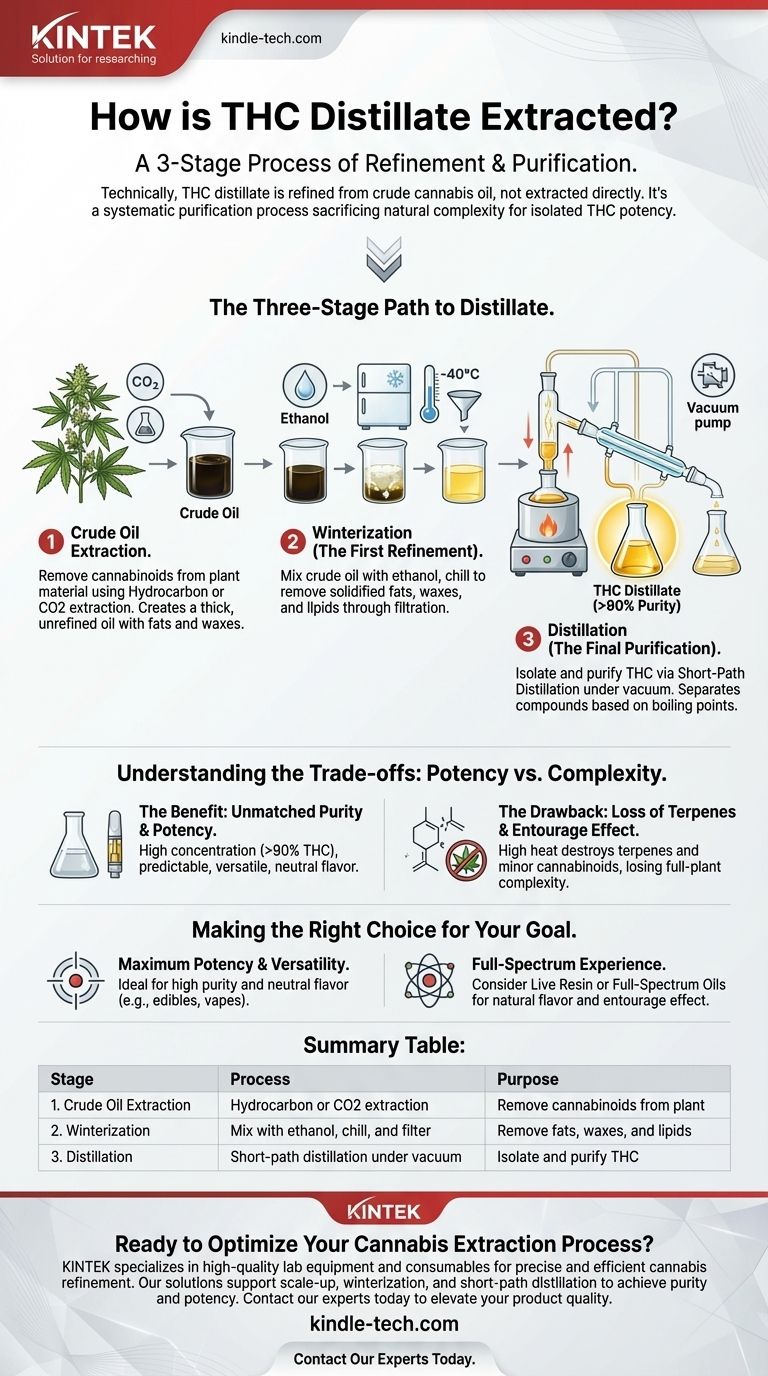

Technically, THC distillate is not extracted directly from the cannabis plant; it is refined from a crude cannabis oil. The creation of distillate is a multi-step process that begins with a primary extraction to create a crude oil, followed by refinement stages like winterization and, finally, the critical step of short-path distillation to isolate the THC molecule.

Creating THC distillate is a process of systematic purification. It sacrifices the plant's natural complexity of terpenes and minor cannabinoids to achieve one primary goal: isolating THC for maximum potency and purity.

The Three-Stage Path to Distillate

Producing a pure THC distillate is a journey of refinement. Each stage removes a different set of undesirable compounds, moving from a raw plant material to a highly concentrated, single-cannabinoid oil.

Stage 1: Crude Oil Extraction

The first step is to get the cannabinoids out of the plant material. This creates a thick, unrefined "crude oil" that contains THC, other cannabinoids, terpenes, waxes, and lipids.

The two most common professional methods are hydrocarbon extraction and CO2 extraction. Both use a solvent to wash the desirable compounds from the plant matter, which is later removed to leave the crude oil behind.

Stage 2: Winterization (The First Refinement)

Crude oil is not yet ready for distillation because it contains fats, waxes, and lipids. Winterization is the process used to remove them.

The crude oil is mixed with ethanol and chilled to extremely low temperatures (e.g., -40°C). This causes the waxes and fats to solidify and separate, allowing them to be filtered out, leaving a cleaner, more fluid oil.

Stage 3: Distillation (The Final Purification)

This is the key step that creates the "distillate." It works on the principle that different chemical compounds have different boiling points. The refined oil is heated under a vacuum in a process called short-path distillation.

As the temperature rises, each compound—first the terpenes, then different cannabinoids—reaches its boiling point, turns into a vapor, and is collected separately. By precisely controlling the temperature, processors can isolate the THC vapor, which is then condensed back into the highly purified liquid we know as distillate.

Understanding the Trade-offs: Potency vs. Complexity

The choice to use distillate involves a clear trade-off. Understanding this is key to knowing if it's the right product for your needs.

The Benefit: Unmatched Purity and Potency

The primary advantage of distillate is its high concentration of THC, often exceeding 90%. This purity makes it potent, predictable, and versatile for use in edibles, vape cartridges, and topicals without adding any plant-like flavor or aroma.

The Drawback: Loss of Terpenes and the "Entourage Effect"

The high heat used in distillation destroys the delicate terpenes, which are the aromatic compounds responsible for the plant's smell and flavor. It also removes minor cannabinoids like CBG or CBN.

Many believe these compounds work together in a synergy known as the entourage effect, where the combined effect is greater than the sum of its parts. By isolating only THC, you lose this potential for a more nuanced, full-plant experience. Processors often add terpenes (either from cannabis or other botanical sources) back into the distillate to create specific flavors and effects.

Making the Right Choice for Your Goal

Selecting a cannabis concentrate depends entirely on what you want to achieve.

- If your primary focus is maximum potency and versatility: THC distillate is the ideal choice due to its high purity and neutral flavor profile.

- If your primary focus is a full-spectrum experience with natural flavor: Consider other concentrates like live resin or full-spectrum oils, which preserve the plant's original terpene and cannabinoid profile.

Ultimately, choosing between distillate and other concentrates is a decision between targeted purity and holistic complexity.

Summary Table:

| Stage | Process | Purpose |

|---|---|---|

| 1. Crude Oil Extraction | Hydrocarbon or CO2 extraction | Remove cannabinoids from plant material |

| 2. Winterization | Mix with ethanol, chill, and filter | Remove fats, waxes, and lipids |

| 3. Distillation | Short-path distillation under vacuum | Isolate and purify THC from other compounds |

Ready to Optimize Your Cannabis Extraction Process?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for precise and efficient cannabis refinement. Whether you're scaling up your distillate production or need reliable equipment for winterization and short-path distillation, our solutions are designed to help you achieve the purity and potency your customers demand.

Contact our experts today to discuss how we can support your laboratory's specific needs and elevate your product quality.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the role of the hydraulic system in hot pressing? Achieve Maximum Material Density and Strength

- What is a magnetron sputtering? A Guide to High-Quality Thin-Film Deposition

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is liquid phase sintering and how is it different from solid state sintering? A Guide to Faster, Denser Materials

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials