The fundamental question isn't how many types of mixers exist, but which mixing mechanism is right for your material. While there are dozens of specialized designs, industrial mixers are primarily categorized by how they move material. The main families are convective mixers, which use an internal agitator, and diffusive (or tumbling) mixers, which rotate the entire vessel to create a cascading flow.

The most critical factor in selecting a mixer is not its name, but matching its mechanical action to your material's properties—such as viscosity, particle size, and fragility. Understanding this relationship is the key to achieving a fast, uniform, and high-quality blend.

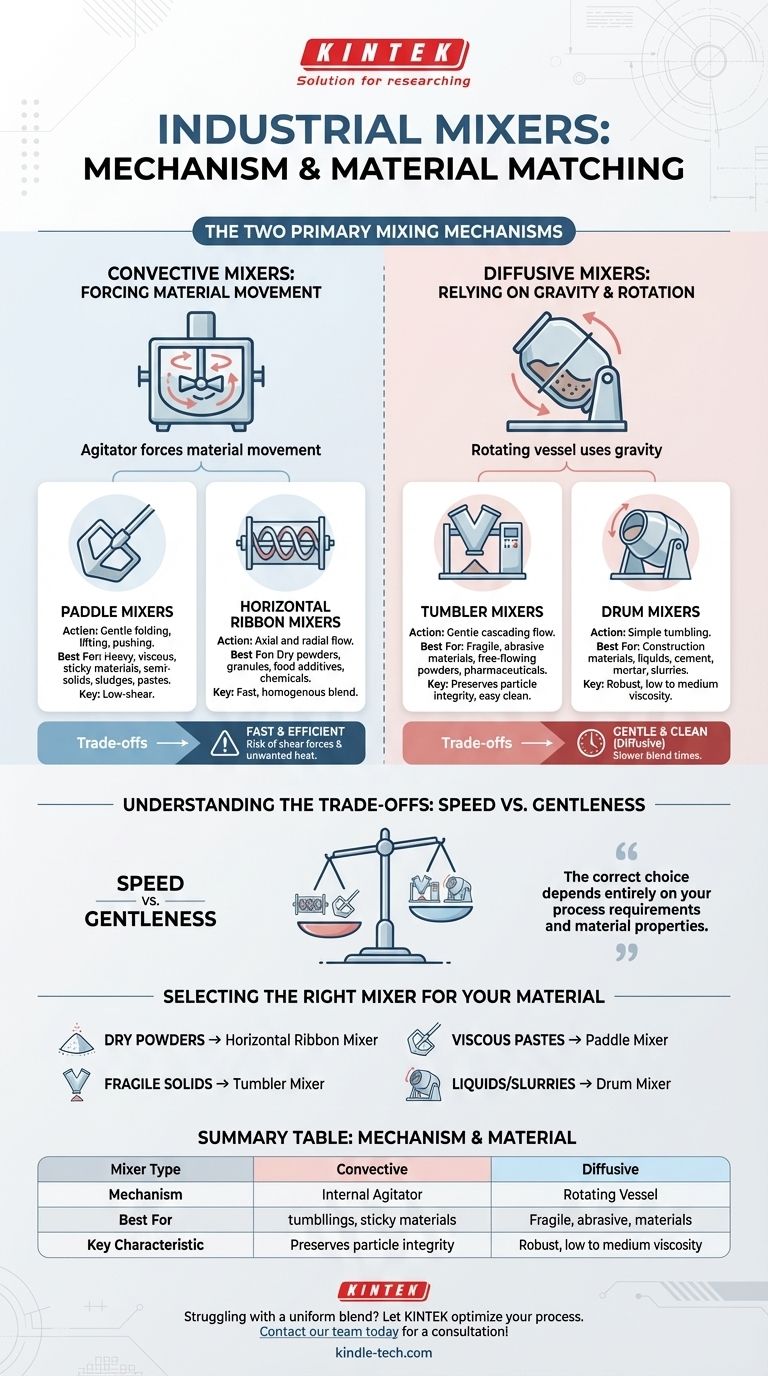

The Two Primary Mixing Mechanisms

Industrial mixing is achieved through two core principles: forcing material to move with an agitator or tumbling the material using gravity. Each approach is suited for different applications and has distinct advantages.

Convective Mixers: Forcing Material Movement

Convective mixers use a powered agitator—such as a paddle, ribbon, or plow—to physically move material within a stationary container. This action is direct, fast, and often imparts shear on the material.

Paddle Mixers These mixers use flat paddles angled to lift and push material, creating a gentle folding action. This makes them highly effective for heavy, viscous, or sticky materials that won't flow easily on their own.

They are a common choice for viscous semi-solids, sludges, and pastes where a thorough but relatively low-shear blend is required.

Horizontal Ribbon Mixers A ribbon mixer is the industry standard for rapidly and efficiently blending dry powders, granules, and other solids. It features an agitator with inner and outer helical ribbons.

The outer ribbon moves material from the ends toward the center, while the inner ribbon moves it from the center toward the ends. This opposing action creates highly effective axial and radial flow, resulting in a fast, homogenous blend for materials like food additives, chemicals, and powdered metals.

Diffusive Mixers: Relying on Gravity and Rotation

Also known as tumbling blenders, these mixers achieve a blend by rotating the entire vessel. As the container turns, the material is lifted up the side and then cascades or tumbles back down, relying on gravity to intermix the particles.

Tumbler Mixers This category includes V-blenders and bin blenders. Because there is no internal agitator, the mixing action is extremely gentle, making it perfect for fragile or abrasive materials.

They excel at blending free-flowing powders or solids that are prone to breaking, such as those found in pharmaceuticals or certain bakery applications. They are also easy to clean, which helps prevent cross-contamination.

Drum Mixers Drum mixers are a simple and robust form of tumbling blender, often used for construction materials and liquids. They rotate an entire drum on its axis to lift and drop the contents.

This method is well-suited for combining materials with low to medium viscosity, such as concrete, mortar, slurries, or liquid coatings.

Understanding the Trade-offs: Speed vs. Gentleness

Choosing between a convective and a diffusive mixer involves a clear trade-off between mixing intensity and material integrity. Neither is universally better; the correct choice depends entirely on your process requirements.

The Cost of Speed: Convective Mixers

Mixers with internal agitators like ribbons and paddles are significantly faster. However, this speed comes at a cost.

The moving parts introduce shear forces that can break down fragile particles, and the friction can generate unwanted heat in the product. They are also more difficult to clean thoroughly than a simple tumbler.

The Benefit of Patience: Diffusive Mixers

Tumbling mixers are prized for their gentle handling of materials, preserving particle size and shape. They consume less energy and are exceptionally easy to clean, making them ideal for high-purity applications.

The downside is longer blend times. They are also less effective for materials that tend to clump or for blends containing particles of vastly different sizes or densities, which can lead to stratification.

Selecting the Right Mixer for Your Material

Your material’s physical properties should be the deciding factor. Use these guidelines to determine the best starting point for your application.

- If you are mixing dry powders or chemicals: A Horizontal Ribbon Mixer offers efficient and thorough blending for most free-flowing solids.

- If you are working with viscous pastes or semi-solids: A Paddle Mixer provides the necessary force to lift and fold heavy, sticky materials.

- If you need to gently blend fragile or abrasive solids: A Tumbler Mixer is the ideal choice to avoid particle degradation and ensure easy cleaning.

- If you are combining liquids, slurries, or cement: A Drum Mixer uses a simple, effective tumbling action suitable for low to medium viscosities.

Ultimately, the most effective mixer is the one whose mechanical action is perfectly suited to the physical properties of your material.

Summary Table:

| Mixer Type | Mixing Mechanism | Best For Material Types | Key Characteristic |

|---|---|---|---|

| Convective (e.g., Ribbon, Paddle) | Internal agitator forces material movement | Dry powders, viscous pastes, semi-solids | Fast, efficient, but can impart shear/heat |

| Diffusive (e.g., Tumbler, Drum) | Rotating vessel uses gravity for tumbling | Fragile, abrasive solids, free-flowing powders | Gentle, easy to clean, but slower blending |

Struggling to achieve a uniform blend? Selecting the right mixer is critical for your product quality and process efficiency. KINTEK specializes in lab equipment and consumables, providing expert guidance and reliable mixing solutions for your specific material needs—from delicate pharmaceuticals to heavy pastes. Let our experts help you optimize your process. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What function does a high-speed rotor-stator homogenizer perform in biomass processing? Optimize Structural Disruption

- How does a constant temperature rotary shaker contribute to evaluating iron nanoparticles? Optimize Dye Degradation

- What are laboratory mixers used for? Achieve Perfect Sample Homogeneity and Reliable Results

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- Why is precision mixing required for concrete corrosion studies? Ensure Data Integrity through Homogenization