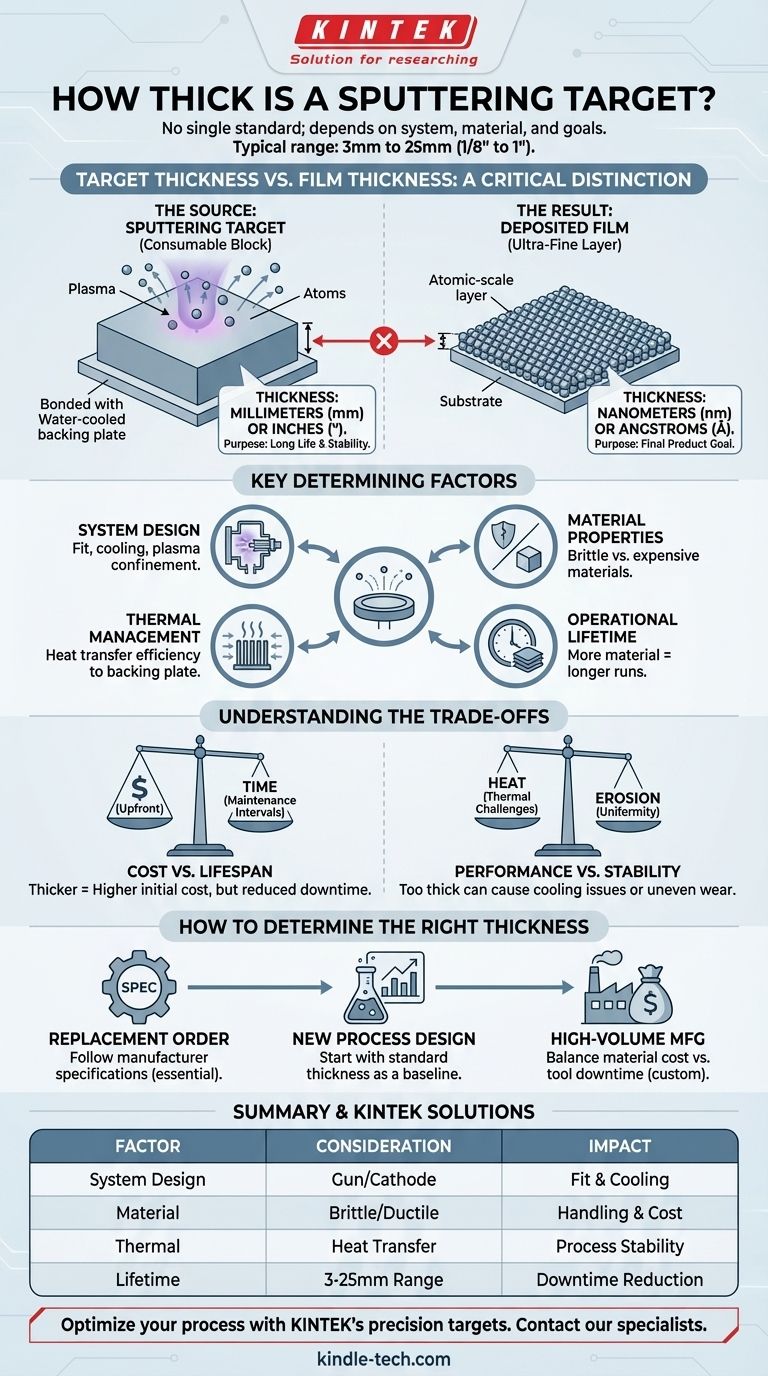

There is no single standard thickness for a sputtering target. The dimension is highly dependent on the specific sputtering system, with typical thicknesses for the target material itself ranging from 3 millimeters to 25 millimeters (about 1/8 inch to 1 inch). This is fundamentally different from the thickness of the coating it produces, which is thousands of times thinner and measured in nanometers or angstroms.

The thickness of a sputtering target is not a universal constant but a critical design parameter. It is determined by the specific requirements of the sputtering tool, the physical properties of the target material, and the desired operational lifetime and thermal performance of the process.

Target Thickness vs. Film Thickness: A Critical Distinction

A common point of confusion is conflating the physical dimensions of the source material (the target) with the dimensions of the final product (the thin film). Understanding this difference is essential.

The Sputtering Target (The Source)

A sputtering target is the bulk, solid block of material that is physically eroded by plasma during the deposition process. It is a consumable component, often bonded to a water-cooled backing plate for thermal management.

Its thickness is measured in millimeters or inches, providing enough material for a long operational life and ensuring mechanical stability.

The Deposited Film (The Result)

The thin film is the ultra-fine layer of material that is deposited onto a substrate. This layer consists of the atoms and molecules ejected from the target's surface.

Its thickness is measured in angstroms or nanometers, often just a few hundred to a few thousand atomic layers thick. This is the goal of the sputtering process.

Key Factors That Determine Target Thickness

The optimal thickness for a sputtering target is a balance of several engineering and economic factors. It is never an arbitrary number.

Sputtering System Design

The most significant factor is the design of the sputtering chamber and cathode assembly, often called the "gun." Manufacturers design their systems to accommodate targets of a specific diameter and thickness to ensure proper fit, effective cooling, and optimal plasma confinement.

Material Properties

The physical characteristics of the target material play a crucial role. Brittle ceramic materials, for example, may require a greater thickness to prevent cracking during bonding or handling. Conversely, extremely expensive materials like gold or platinum may be specified with a minimal thickness to reduce initial cost.

Thermal Management

Sputtering generates a significant amount of heat. The target's thickness directly impacts how efficiently this heat can be transferred to the water-cooled backing plate it is bonded to. An excessively thick target can lead to poor cooling, which may cause the target to crack or the sputtering rate to become unstable.

Desired Operational Lifetime

A thicker target contains more sputterable material and will, therefore, last longer before needing replacement. In high-volume manufacturing, thicker targets are often preferred to minimize tool downtime, even if the initial cost is higher.

Understanding the Trade-offs

Choosing or specifying a target thickness involves balancing competing priorities.

Cost vs. Lifespan

A thicker target has a higher upfront material cost. However, it extends the time between maintenance cycles, reducing labor costs and equipment downtime. The decision often comes down to a calculation of the total cost of ownership.

Performance vs. Stability

While a thick target lasts longer, it can present thermal challenges. Inefficient heat removal can cause the material's properties to change or lead to uneven erosion, known as "racetrack" formation, which ultimately reduces the usable portion of the target material.

Standardization vs. Customization

Most research and development systems use standardized target sizes (e.g., 2 inches in diameter, 6 mm thick) for cost-effectiveness and availability. Large-scale industrial systems, however, often use custom-designed, larger, and sometimes non-planar targets optimized for a specific application.

How to Determine the Right Thickness for Your Needs

The correct approach depends entirely on your specific context and goals.

- If you are ordering a replacement target: Your primary guide must be the specifications provided by the manufacturer of your sputtering system. Deviating from this can lead to improper fit, poor cooling, and inconsistent results.

- If you are designing a new process: Begin with the standard thickness recommended for your tool. This provides a reliable baseline for developing your process parameters before considering optimizations.

- If you are focused on high-volume manufacturing: Your goal is balancing material cost against tool downtime. You may work with a target supplier to specify a thickness that maximizes operational life without compromising thermal stability.

Ultimately, viewing target thickness as an engineered parameter—not just a simple dimension—is the key to a stable and efficient sputtering process.

Summary Table:

| Factor | Typical Range/Consideration | Key Impact |

|---|---|---|

| Sputtering System Design | Specific to cathode/gun | Determines fit, cooling, and plasma stability |

| Material Properties | Brittle ceramics vs. ductile metals | Affects mechanical stability and handling requirements |

| Thermal Management | Thickness impacts heat transfer to backing plate | Critical for process stability and preventing target damage |

| Operational Lifetime | 3mm to 25mm (1/8" to 1") | Thicker targets last longer, reducing downtime |

Optimize your sputtering process with the right target specifications.

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including precision-engineered sputtering targets. Whether you need a standard replacement or a custom solution for high-volume manufacturing, our experts can help you select the ideal thickness and material to maximize your tool's performance, lifespan, and cost-efficiency.

Contact our specialists today for a consultation and ensure your deposition process runs smoothly and reliably.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition