In short, determining the ash content of a drug is a critical quality control test used to measure the total amount of inorganic, noncombustible material present. This measurement serves as a fundamental indicator of the drug's purity, identity, and consistency, ensuring it is free from undesirable inorganic impurities or adulterants.

Ash content analysis is not simply about measuring minerals; it is a crucial, non-specific test that acts as a sentinel for quality. A value outside the expected range signals a potential failure in purity, identity, or manufacturing consistency that requires immediate investigation.

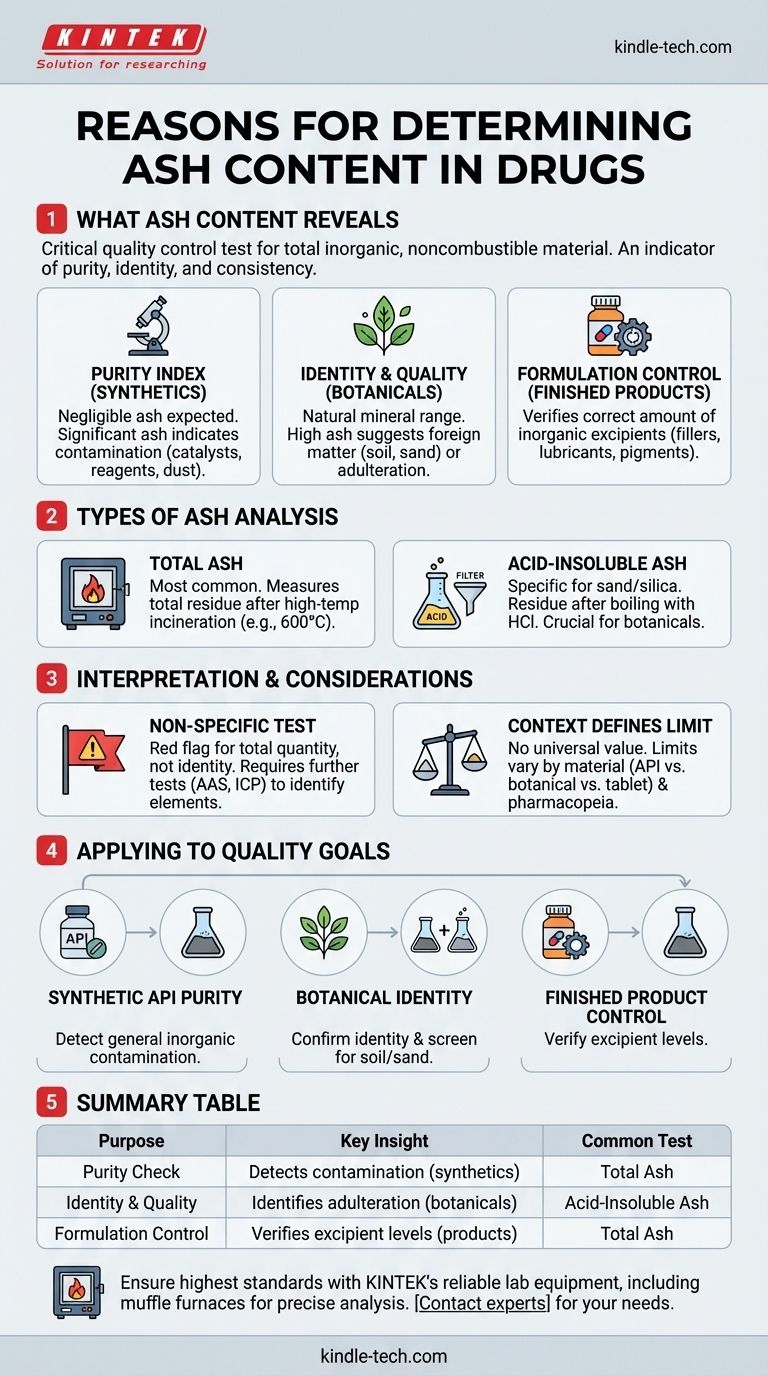

What Ash Content Reveals About a Drug

The value obtained from an ash test provides several key insights into the quality of a pharmaceutical material. It is a simple test that can reveal complex problems.

An Index of Purity

For most pure, organic drug substances, the ash content should be negligible. The presence of any significant ash indicates contamination.

These inorganic impurities can originate from various sources in the manufacturing process, such as residual metal catalysts, inorganic reagents, or environmental contaminants like dust and dirt. Pharmacopeias set strict limits on ash content for this reason.

A Test of Identity and Quality for Botanicals

For crude drugs derived from plants, ash analysis is essential for identification and quality assessment. Every plant has a natural and relatively constant range of mineral content absorbed from its growing environment.

An ash value that is higher than the established range suggests the presence of foreign matter like soil or sand from improper harvesting and cleaning. It can also indicate deliberate adulteration, where a valuable botanical is "cut" with cheaper inorganic material to increase its weight.

A Control for Formulated Products

In finished drug products like tablets or capsules, inorganic materials (excipients) are often added intentionally. These can include fillers like calcium carbonate, lubricants like talc, or pigments like titanium dioxide.

In this context, the ash test is used to confirm that the correct amount of these inorganic excipients has been added. It acts as a verification step to ensure the final product composition matches the intended formulation.

Understanding the Types of Ash Analysis

The specific information required determines which type of ash test is performed. Each variation provides a different piece of the quality puzzle.

Total Ash

This is the most common method. It measures the total amount of residue remaining after the sample is completely incinerated in a muffle furnace at a high temperature (e.g., 600°C). This value represents all the inorganic material present in the drug.

Acid-Insoluble Ash

This is a more specific test used to quantify contaminants like sand and silica. After determining the total ash, the residue is boiled with dilute hydrochloric acid. Any remaining material that does not dissolve is the acid-insoluble ash.

This test is particularly valuable for botanical drugs, as it effectively isolates soil and sand contamination from the naturally occurring, acid-soluble minerals of the plant itself.

Interpreting the Results: Key Considerations

While powerful, the ash test is a blunt instrument. Understanding its limitations is crucial for accurate interpretation.

It Is a Non-Specific Test

The primary limitation of ash analysis is that it is non-specific. It tells you the total quantity of inorganic material but gives no information about the identity of the individual elements.

A high ash value is a red flag. It tells you there is a problem, but it does not tell you what the problem is. Further analysis using techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) is required to identify and quantify specific toxic heavy metals or other elemental impurities.

Context Defines the Limit

There is no universal "good" or "bad" ash value. The acceptable limit is entirely dependent on the material being tested.

A pure synthetic drug may have a limit of less than 0.1%, while a specific botanical drug might have an acceptable limit of up to 8%. A formulated tablet containing inorganic excipients will have its own, much higher specified range. The official pharmacopeia (such as the USP or BP) or internal company specifications define the acceptable range for each specific product.

Applying This to Your Quality Goal

Your objective dictates how you should interpret and use ash content data.

- If your primary focus is ensuring the purity of a synthetic API: Use total ash as a fundamental limit test to detect general inorganic contamination from the synthesis or purification process.

- If your primary focus is verifying the quality of a botanical drug: Use both total ash and acid-insoluble ash to confirm identity and screen for foreign matter like soil and sand.

- If your primary focus is controlling the composition of a finished drug product: Use total ash to verify that the correct quantity of inorganic functional excipients is present in the final formulation.

Ultimately, determining ash content is a fundamental and cost-effective tool for safeguarding drug quality, from raw material to finished product.

Summary Table:

| Purpose of Ash Content Test | Key Insight | Common Test Type |

|---|---|---|

| Purity Check | Detects inorganic contamination in synthetic drugs | Total Ash |

| Identity & Quality (Botanicals) | Identifies adulteration (e.g., sand, soil) | Acid-Insoluble Ash |

| Formulation Control | Verifies inorganic excipient levels in final products | Total Ash |

Ensure the highest standards of purity and consistency in your pharmaceutical products. KINTEK specializes in providing reliable lab equipment, including muffle furnaces essential for precise ash content analysis. Whether you are testing synthetic APIs, botanical drugs, or finished formulations, our solutions help you meet pharmacopeial requirements efficiently. Contact our experts today to discuss your specific quality control needs and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do you cool a muffle furnace? Safeguard your equipment and samples from thermal shock.

- What is the importance of melting process? Master the Foundation of Metal Production

- What PPE is required for a muffle furnace? Essential Gear for High-Temperature Safety

- What is a furnace classified as? Understand the Two Main Types for Your Application

- What is the difference between a lab furnace and a lab oven? Choose the Right Heating Tool for Your Lab