A sputtering target's specifications are a comprehensive set of material, physical, and geometric properties that define its quality and performance. These include critical metrics like material purity, density, grain size, and dimensional tolerance, which are far more stringent than those for standard bulk materials because they directly control the quality and consistency of the final deposited thin film.

The core principle is that a sputtering target is not merely a source material; it is a precision component. Its specifications must be carefully matched to the deposition system and the functional requirements of the thin film being created, as each property directly influences the sputtering rate, film purity, and process stability.

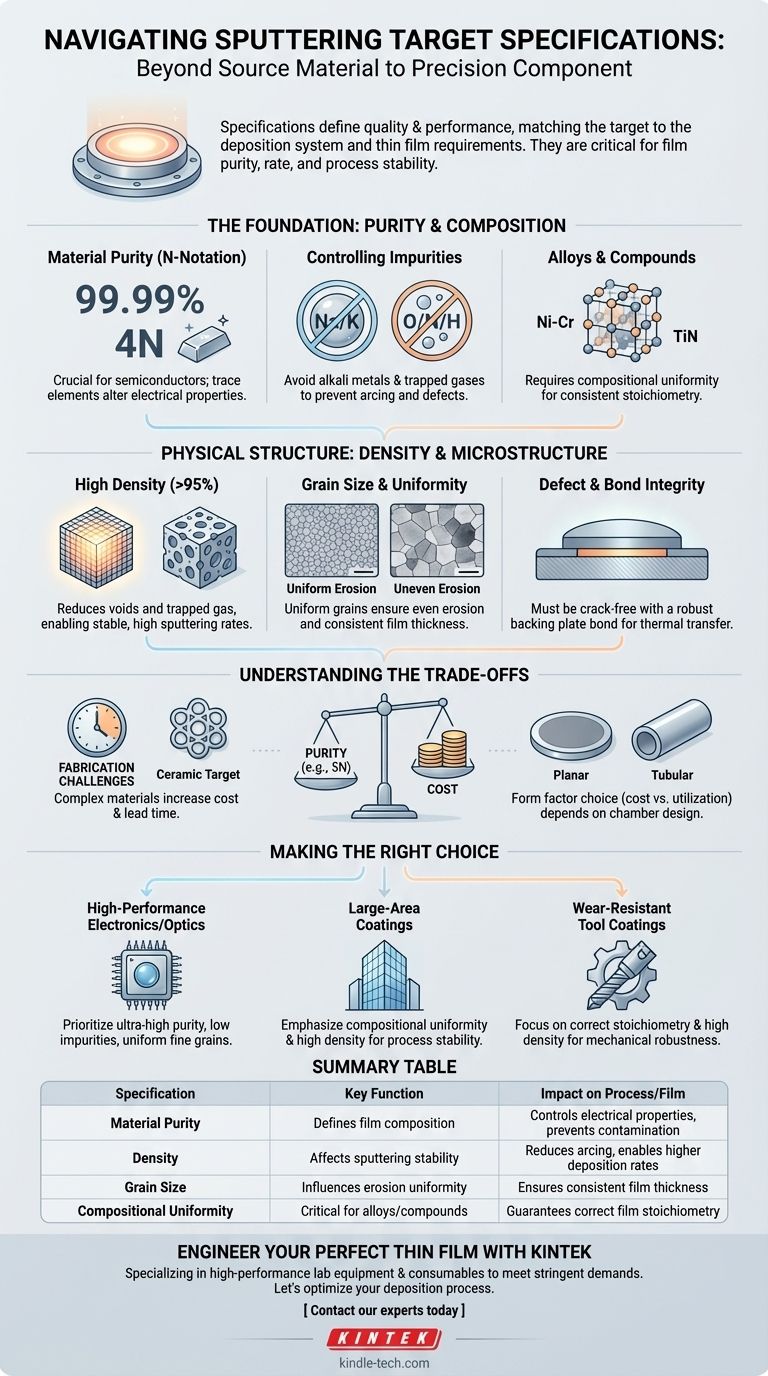

The Foundation: Purity and Composition

The chemical makeup of the target is the most fundamental aspect, as it is what ultimately forms your film.

Defining Material Purity

The purity of the target material is paramount. It is typically expressed as a percentage (e.g., 99.99%) or using "N" notation (e.g., 4N for 99.99%, 5N for 99.999%).

High purity is essential for applications like semiconductors and electronics, where even trace amounts of an unwanted element can drastically alter the film's electrical properties and render a device useless.

Controlling Specific Impurities

Beyond overall purity, the type and concentration of specific impurities are critical. For example, alkali metal impurities (Na, K) are highly detrimental in semiconductor manufacturing.

Gaseous impurities like oxygen, nitrogen, and hydrogen trapped within the target are also a major concern, as they can cause arcing during sputtering or become incorporated into the film, creating defects.

Alloys and Compounds

Many applications use targets that are not pure elements but precise alloys (e.g., Nickel-Chromium) or compounds (e.g., Titanium Nitride, Indium Tin Oxide).

For these materials, the key specification becomes compositional uniformity. The elements must be homogeneously mixed throughout the target to ensure the deposited film has a consistent and correct stoichiometry from start to finish.

Physical Structure: Density and Microstructure

The internal physical structure of the target has a direct impact on the stability and efficiency of the sputtering process itself.

The Importance of High Density

Density, measured as a percentage of the material's theoretical maximum density, is a key performance indicator. High-density targets (typically >95%) are crucial.

Low density implies the presence of internal voids. These voids can trap gas, leading to uncontrolled gas release and arcing during the process. A denser target also allows for a higher, more stable sputtering rate.

Grain Size and Uniformity

For metallic and alloy targets, a small and uniform grain size is highly desirable. Large or non-uniform grains will sputter at different rates, leading to uneven erosion of the target surface.

This uneven erosion translates directly into poor thickness uniformity in the deposited film. Therefore, controlling the target's microstructure is essential for creating consistent coatings.

Defect and Bond Integrity

The target must be free of cracks, inclusions, or other physical defects. These act as points of failure and can generate particles that contaminate the substrate.

Furthermore, the target material is typically bonded to a metallic "backing plate," which provides mechanical support and facilitates water cooling. The integrity of this bond is critical for efficient thermal transfer to prevent the target from overheating and cracking.

Understanding the Trade-offs

Choosing the right specifications is an exercise in balancing performance requirements with practical constraints.

Purity vs. Cost

The single biggest trade-off is purity versus cost. Each additional "nine" in purity (e.g., moving from 4N to 5N) can increase the price significantly due to the complex refining processes required.

For applications like architectural glass, a 3N target may be perfectly sufficient, whereas for advanced microelectronics, 5N or 6N purity is non-negotiable. Over-specifying purity is a common and costly mistake.

Fabrication Challenges

Some materials, particularly ceramics and brittle intermetallic compounds, are notoriously difficult to fabricate into high-density, defect-free targets.

This manufacturing complexity directly impacts cost and lead time. A simple aluminum target may be readily available, while a large, crack-free ceramic target might require a specialized manufacturing process and a lead time of several weeks or months.

Form Factor and Utilization

Targets come in various shapes, most commonly planar (flat/rectangular) and tubular (cylindrical). Planar targets are often simpler and cheaper to manufacture.

However, tubular targets, used in certain large-area coating systems, can offer much higher material utilization, reducing the cost per substrate over the target's lifetime. The choice is dictated by the design of your sputtering chamber.

Making the Right Choice for Your Application

Ultimately, the target specifications you require are defined by your end goal.

- If your primary focus is high-performance electronics or optics: Prioritize ultra-high purity, extremely low specific impurities, and a uniform, fine-grain microstructure to ensure predictable film properties.

- If your primary focus is large-area protective or architectural coatings: Emphasize compositional uniformity and high density for process stability, but select a purity grade and form factor that provides the best cost-effectiveness for your operation.

- If your primary focus is wear-resistant tool coatings: Concentrate on achieving the correct stoichiometry in compound targets and ensuring high density to produce a mechanically robust film free of defects.

Mastering these specifications transforms the sputtering target from a simple consumable into a precision instrument for engineering your desired film.

Summary Table:

| Specification | Key Function | Impact on Process/Film |

|---|---|---|

| Material Purity | Defines film composition | Controls electrical properties, prevents contamination |

| Density | Affects sputtering stability | Reduces arcing, enables higher deposition rates |

| Grain Size | Influences erosion uniformity | Ensures consistent film thickness |

| Compositional Uniformity | Critical for alloys/compounds | Guarantees correct film stoichiometry |

Engineer Your Perfect Thin Film with KINTEK

Choosing the right sputtering target specifications is critical for your lab's success. Whether you are developing advanced semiconductors, high-performance optics, or durable protective coatings, the precise purity, density, and microstructure of your target define your results.

KINTEK specializes in high-performance lab equipment and consumables, providing sputtering targets engineered to meet the stringent demands of modern research and production. We help you navigate the trade-offs between purity, cost, and manufacturability to select the ideal target for your specific application, ensuring process stability and superior film quality.

Let's optimize your deposition process. Contact our experts today to discuss your project requirements and find the perfect sputtering solution.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Domes for Industrial and Scientific Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- Which is better CVD or HPHT lab-grown diamonds? Focus on Quality, Not the Method.

- Can carbon nanotubes replace silicon? The Future of Computing Beyond Moore's Law

- What is the function of film deposition? To Engineer Superior Surface Properties

- What method is used to make thin films? A Guide to Chemical and Physical Deposition

- What is sputtering effect? A Complete Guide to Thin Film Deposition Technology

- How are carbon nanotubes synthesized by arc discharge? The Original High-Temperature Method Explained

- What are sputtering targets? Essential for High-Quality Thin Film Deposition

- What are the applications of semiconductor thin films? Powering the Core of Modern Electronics