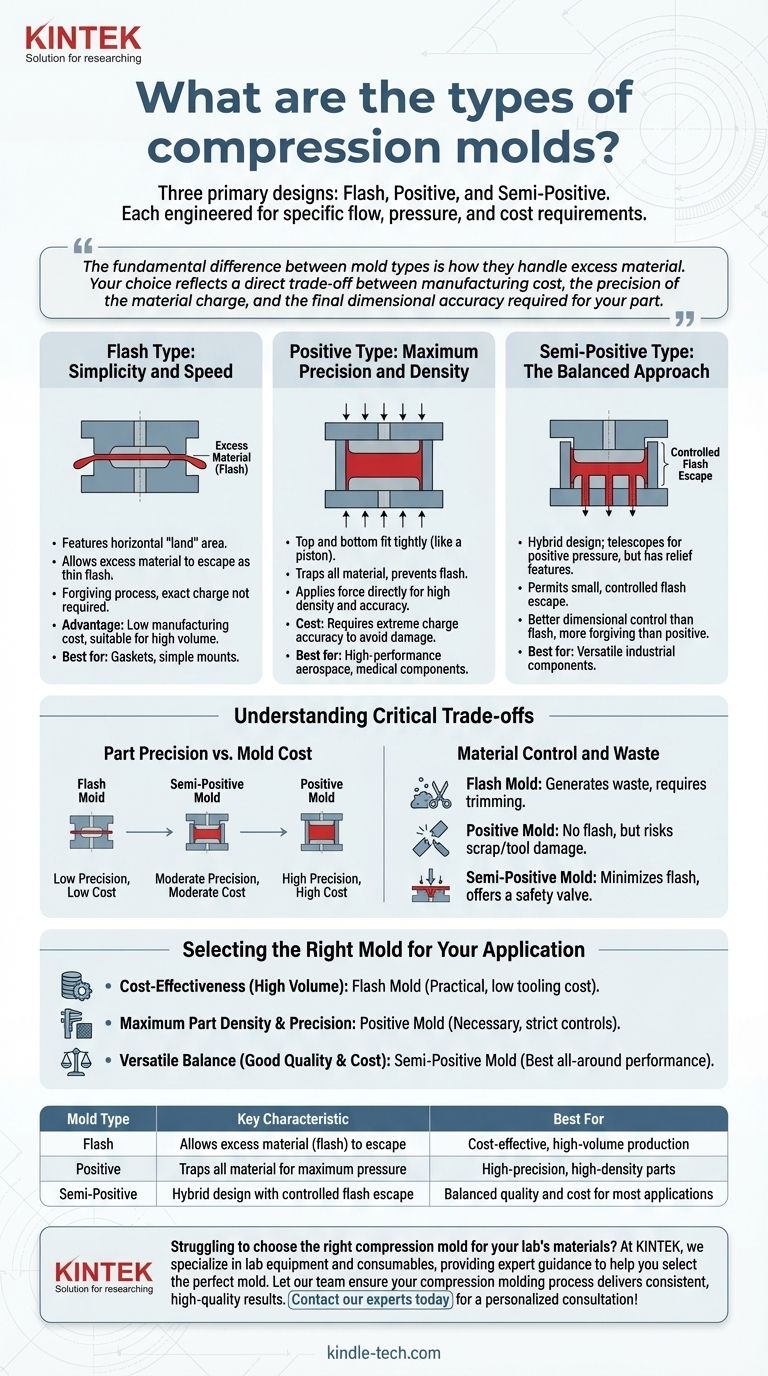

There are three primary types of compression molds: flash, positive, and semi-positive. Each design is engineered to control the flow and pressure on the molding material differently, directly impacting the final part's precision, density, and cost. The choice among them depends entirely on the specific requirements of the component being produced.

The fundamental difference between mold types is how they handle excess material. Your choice reflects a direct trade-off between manufacturing cost, the precision of the material charge, and the final dimensional accuracy required for your part.

The Three Core Mold Designs Explained

Understanding each design's mechanics reveals its ideal use case. The primary distinction lies in whether, and how, the mold allows excess material (known as "flash") to escape as the mold closes under pressure.

Flash Type: Simplicity and Speed

A flash mold is the simplest and most common design. It features a horizontal "land" area around the mold cavity.

As the mold closes, this land allows excess material to be squeezed out, forming a thin sheet of flash. This makes the process forgiving, as the exact amount of material (the "charge") does not need to be perfectly measured.

The primary advantage is its low manufacturing cost and suitability for high-volume production where minor imperfections are acceptable.

Positive Type: Maximum Precision and Density

A positive mold is designed for maximum pressure and material containment. The top and bottom halves of the mold fit together with a tight tolerance, almost like a piston in a cylinder.

This design traps all the material within the cavity, preventing any flash from escaping. All the force is applied directly to the material, resulting in parts with very high density and excellent dimensional accuracy.

However, this precision comes at a cost. The material charge must be weighed with extreme accuracy to avoid either under-filling the cavity or creating excessive pressure that could damage the expensive mold.

Semi-Positive Type: The Balanced Approach

The semi-positive mold is a hybrid design that captures the benefits of both flash and positive molds.

It allows the mold halves to telescope together for a short distance to apply positive pressure, but it also incorporates features like vertical lands or relief vents. This permits a small, controlled amount of flash to escape once a specific pressure is reached.

This design provides much better dimensional control and density than a flash mold while being more forgiving on material charge than a fully positive mold.

Understanding the Critical Trade-offs

Selecting a mold type is an engineering decision based on balancing three key factors: cost, material control, and the required quality of the final part.

Part Precision vs. Mold Cost

There is a direct relationship between the cost of the mold and the precision of the part it produces.

- Flash Mold: Lowest cost, lowest precision. Ideal for parts like gaskets or simple mounts where exact dimensions are less critical.

- Positive Mold: Highest cost, highest precision. Used for high-performance components in aerospace, medical, or electrical applications.

- Semi-Positive Mold: A moderate cost for good-to-high precision. It is a versatile workhorse for a wide range of industrial components.

Material Control and Waste

How the mold handles the material charge is a defining factor.

Flash molds generate waste material and require a secondary trimming operation, adding labor and cost to the process. Positive molds create no flash but risk scrap parts or tool damage if the charge is incorrect.

The semi-positive design offers a compromise, minimizing flash while providing a safety valve for slight variations in the material charge.

Selecting the Right Mold for Your Application

Your final choice should be guided by the end-use requirements of your component.

- If your primary focus is cost-effectiveness for high-volume production: The flash mold is the most practical choice due to its low tooling cost and forgiving nature.

- If your primary focus is maximum part density and dimensional accuracy: The positive mold is necessary, despite its higher cost and strict process controls.

- If your primary focus is a versatile balance of good quality and reasonable cost: The semi-positive mold offers the best all-around performance for most industrial applications.

Ultimately, aligning your mold design with your part's specific engineering and economic goals is the key to successful compression molding.

Summary Table:

| Mold Type | Key Characteristic | Best For |

|---|---|---|

| Flash | Allows excess material (flash) to escape | Cost-effective, high-volume production |

| Positive | Traps all material for maximum pressure | High-precision, high-density parts |

| Semi-Positive | Hybrid design with controlled flash escape | Balanced quality and cost for most applications |

Struggling to choose the right compression mold for your lab's materials? The wrong mold design can lead to imprecise parts, wasted material, and increased costs. At KINTEK, we specialize in lab equipment and consumables, providing expert guidance to help you select the perfect mold for your specific application—whether you need high-volume efficiency with a flash mold or maximum precision with a positive mold. Let our team ensure your compression molding process delivers consistent, high-quality results. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- Small Injection Molding Machine for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Cutting Tool Blanks for Precision Machining

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What are the different types of molds? A Guide to Choosing the Right Process for Your Product

- How do graphite molds contribute to the chemical environment during the vacuum hot pressing of Cu-Cr-Nb alloys?

- What is the process of mould manufacturing? From CAD Design to Precision Machining

- What role do high-strength molds play in all-solid-state battery pelletizing? Achieve Uniform Density & Precision

- What type of mold is used for the compression molding of shallow or flat parts? The Definitive Guide to Flash-Type Molds

- What are the primary functions of graphite molds? Optimize Your Cu-Ti3SiC2 Composite Sintering Today

- How long do you leave a ceramic slip in a mold? Master Timing for Perfect Casts

- What are the functions of a graphite mold? Essential Roles in Vacuum Hot Pressing for High-Entropy Alloys