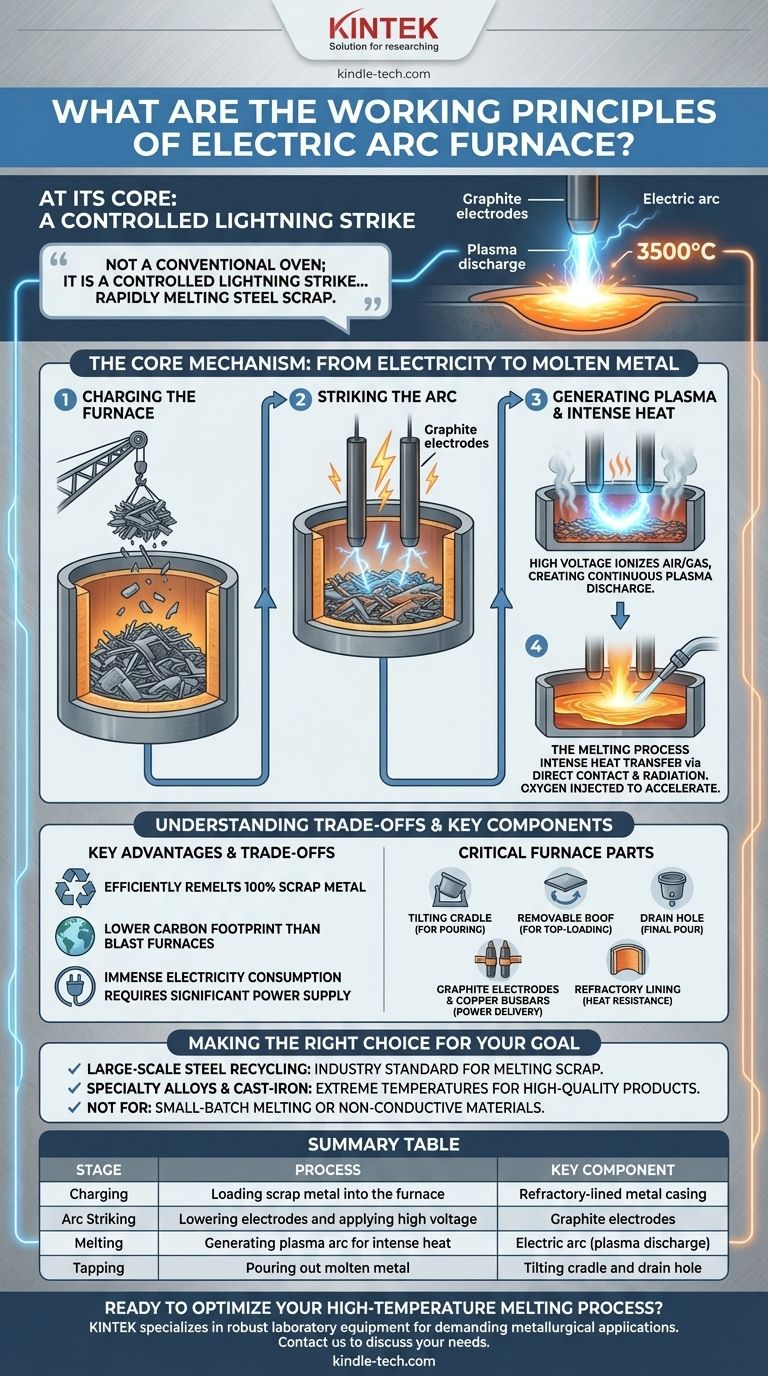

At its core, an electric arc furnace (EAF) operates on a simple but powerful principle. It uses a controlled, high-energy electrical discharge—an arc—to generate immense heat. This arc, forming between graphite electrodes and the metal inside, creates a plasma discharge that can reach temperatures up to 3500°C, rapidly melting steel scrap or other materials.

An electric arc furnace is not a conventional oven; it is a controlled lightning strike. By creating an electrical arc directly through a charge of metal, it generates a plasma discharge with temperatures hot enough to melt large quantities of steel almost instantly, making it a cornerstone of modern metal recycling.

The Core Mechanism: From Electricity to Molten Metal

Understanding the EAF process is to understand the controlled application of raw electrical power. The operation follows a precise sequence to transform solid scrap into a liquid product.

Step 1: Charging the Furnace

The process begins by loading the furnace. A heavy, metal casing lined with heat-resistant refractory material is filled with the raw material, known as the "charge." This charge is most commonly shredded scrap steel, old beams, or other recycled metal products.

Step 2: Striking the Arc

Once loaded, a removable roof is positioned, and large graphite electrodes are lowered into the furnace until they are just above the metal charge. A massive amount of high-voltage electricity is then applied to the electrodes.

Step 3: Generating Plasma and Intense Heat

The high voltage ionizes the air or gas between the electrode tips and the metal, creating a conductive path. This forms the electric arc, which is a continuous plasma discharge. This arc is the source of the extreme heat, capable of reaching temperatures that far exceed the melting point of steel.

Step 4: The Melting Process

The intense heat from the arc is transferred to the metal charge through both direct contact and powerful radiation. The metal begins to melt rapidly. To accelerate the process and refine the steel, oxygen is often injected into the furnace.

Understanding the Trade-offs and Key Components

The EAF's design is purpose-built for high-temperature, heavy-duty work. Its effectiveness comes with specific operational considerations.

The Power of Scrap Recycling

The EAF's primary advantage is its ability to efficiently remelt 100% scrap metal. This makes it a critical tool for steel recycling, reducing the need for virgin iron ore and lowering the carbon footprint of steel production compared to traditional blast furnaces.

Key Furnace Components

The furnace itself consists of several critical parts. A tilting cradle allows the entire furnace housing to be rocked forward to pour out the molten metal. A removable roof allows for quick top-loading of scrap, and a drain hole facilitates the final pour. The entire system is powered by a robust electrical infrastructure, including copper busbars that deliver current to the electrodes.

High Energy Consumption

The primary trade-off is immense electricity consumption. Creating and sustaining an arc hot enough to melt tons of steel requires a significant and stable power supply, making energy costs a major operational factor. The process is best suited for large-scale production where the volume justifies the power demand.

Making the Right Choice for Your Goal

The electric arc furnace is a specialized tool designed for specific metallurgical objectives. Its application depends entirely on the desired outcome and scale of production.

- If your primary focus is large-scale steel recycling: The EAF is the industry standard for efficiently melting shredded scrap, beams, and other large metal forms into new steel.

- If your primary focus is producing specialty alloys or cast-iron products: An EAF provides the extreme temperatures and controlled environment needed to create high-quality, specific metal products from scrap or other raw materials.

- If your primary focus is small-batch melting or processing non-conductive materials: The EAF is likely not the correct tool, as its principle relies on creating an arc with a conductive metal charge at a large scale.

By harnessing the fundamental power of an electric arc, the EAF provides a fast and effective method for high-temperature metallurgy.

Summary Table:

| Stage | Process | Key Component |

|---|---|---|

| Charging | Loading scrap metal into the furnace | Refractory-lined metal casing |

| Arc Striking | Lowering electrodes and applying high voltage | Graphite electrodes |

| Melting | Generating plasma arc for intense heat | Electric arc (plasma discharge) |

| Tapping | Pouring out molten metal | Tilting cradle and drain hole |

Ready to Optimize Your High-Temperature Melting Process?

At KINTEK, we specialize in providing robust laboratory equipment and consumables for demanding metallurgical applications. Whether you are involved in material testing, alloy development, or process optimization, our solutions are designed to meet the rigorous demands of high-temperature environments.

Let our experts help you select the right equipment for your specific needs. Contact us today to discuss how KINTEK can support your laboratory's success in metal processing and analysis.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation