In essence, a sputtering target is the source material used to create a thin film coating in a physical vapor deposition (PVD) process. It is a solid piece, often flat or cylindrical, made of the exact material you wish to deposit onto a substrate. During sputtering, this target is bombarded with energized ions, which eject atoms from its surface that then travel and form a uniform coating on the desired object.

The sputtering target should not be viewed as a mere component, but as the foundational source of the final coating. The purity, shape, and integrity of the target directly dictate the quality, performance, and uniformity of the thin film you produce.

The Role of the Target in the Sputtering Process

To understand the target, you must first understand its function within the sputtering system. The target is the starting point and the single most critical element for the material being deposited.

The Source of the Thin Film

The target is composed of the specific metal, alloy, or ceramic that you intend to use as a coating. If you need to create a titanium nitride film, you will use a titanium target in a nitrogen gas environment. The target is the reservoir of atoms for the coating.

The Subject of Ion Bombardment

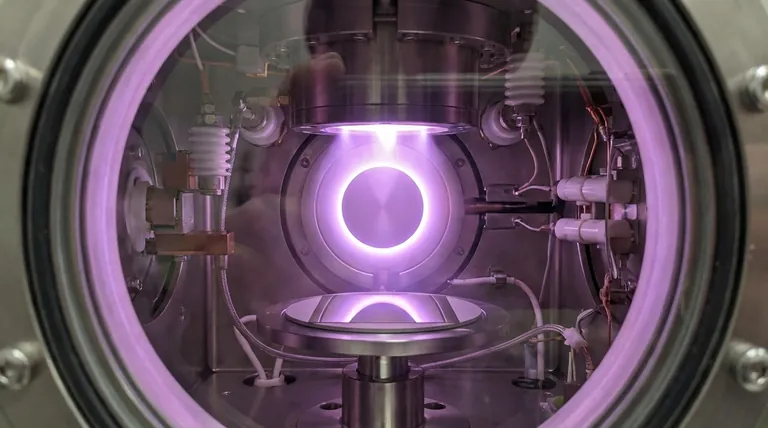

In a vacuum chamber, an inert gas like argon is introduced and ionized, creating a plasma. An electric field accelerates these positive ions, causing them to collide with the negatively charged target surface with great force.

The Ejection and Deposition Mechanism

This high-energy bombardment physically knocks out, or "sputters," atoms from the target material. These ejected atoms travel through the vacuum chamber and deposit onto the substrate (the object to be coated), building up a thin film layer by layer. This process is what leads to coatings with strong adhesion and excellent thickness uniformity.

Key Characteristics of a Sputtering Target

The physical and material properties of the target are not trivial details; they are critical parameters that control the outcome of the deposition process.

Material Purity

The purity of the target material is paramount, as any impurities within the target will be transferred directly into the deposited film, potentially compromising its electrical, optical, or mechanical properties.

Physical Form Factor

Targets are typically produced in planar (flat discs) or cylindrical shapes. The choice depends on the specific sputtering system design and the desired deposition uniformity. The target's surface is always larger than the area being sputtered to prevent the unintended sputtering of system components.

Power and Sputtering Rate

The type and amount of power applied to the target directly influence the process. For example, in RF sputtering, the effective power delivered is about half of that in DC sputtering, which affects the rate at which atoms are ejected and the film is grown.

Understanding the Inefficiencies and Pitfalls

While sputtering is a highly controlled process, its interaction with the target introduces known challenges that must be managed for cost-effective and repeatable production.

The "Race Track" Phenomenon

During sputtering, the ion bombardment is often not uniform across the entire target face, especially in systems using magnets (magnetron sputtering). The ions tend to focus on a specific annular area, causing the target to erode more deeply in that region.

Uneven Material Utilization

This concentrated erosion creates a distinct groove known as a race track. Because sputtering is focused here, a significant portion of the target material outside this track remains unused. This lowers the effective material utilization, increasing costs.

Target Lifespan and Replacement

The depth of the race track ultimately determines the usable life of the target. Once the groove becomes too deep, it risks compromising the system's integrity or the film's quality. This is why a "low target replacement frequency" is a desirable trait for any mass production process.

Making the Right Choice for Your Goal

The selection and management of a sputtering target should be directly aligned with the primary objective of your thin film application.

- If your primary focus is creating ultra-pure films: The certified purity of the target material is your most critical specification.

- If your primary focus is high-volume manufacturing: You must select a target designed for high utilization and a sputtering process that minimizes the race track effect to control costs.

- If your primary focus is depositing complex alloys: The target must be fabricated with exceptional homogeneity to ensure the composition of the sputtered film is identical to the target itself.

Ultimately, recognizing that the target is the direct blueprint for your final coating is the key to achieving consistent, high-quality results in thin film deposition.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Source material for creating thin film coatings in Physical Vapor Deposition (PVD). |

| Process Role | Atoms are ejected from the target surface via ion bombardment to deposit onto a substrate. |

| Critical Characteristics | Material purity, physical form factor (planar/cylindrical), and power handling. |

| Key Consideration | Target selection directly impacts film quality, uniformity, and production cost-efficiency. |

Achieve Consistent, High-Quality Thin Films with KINTEK

Your sputtering target is the blueprint for your final coating. Selecting the right one is critical to the success of your application, whether you require ultra-pure films for R&D or cost-effective, high-volume production.

At KINTEK, we specialize in providing high-purity sputtering targets and expert consultation for all your laboratory equipment needs. We understand that the right target material directly dictates the performance of your thin film.

Let us help you optimize your deposition process. Contact our experts today to discuss your specific requirements and discover how KINTEK's solutions can enhance your lab's efficiency and results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electrolytic Electrochemical Cell for Coating Evaluation

- Vacuum Cold Trap Direct Cold Trap Chiller

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- How well does graphite transfer heat? Unlock Superior Thermal Management for Your Electronics

- What is the function of temperature control during the drying stage of the biomass gasification process? Optimize Yield

- What are the advantages of using deionized water in HHIP? Superior Density and Microstructural Integrity

- What materials are hot isostatically pressed? Achieve Full Density in Critical Components

- What are the three sample preparation techniques? Master the Key Stages for Accurate Analysis

- Why is a precision drying oven required for TiO2 wet gel? Ensure Structural Integrity & Porosity

- What is the fast pyrolysis method? A Rapid Process for Converting Biomass to Bio-Oil

- What is the role of vacuum drying equipment in the processing of SiC/B4C composite powders? Prevent Agglomeration Today