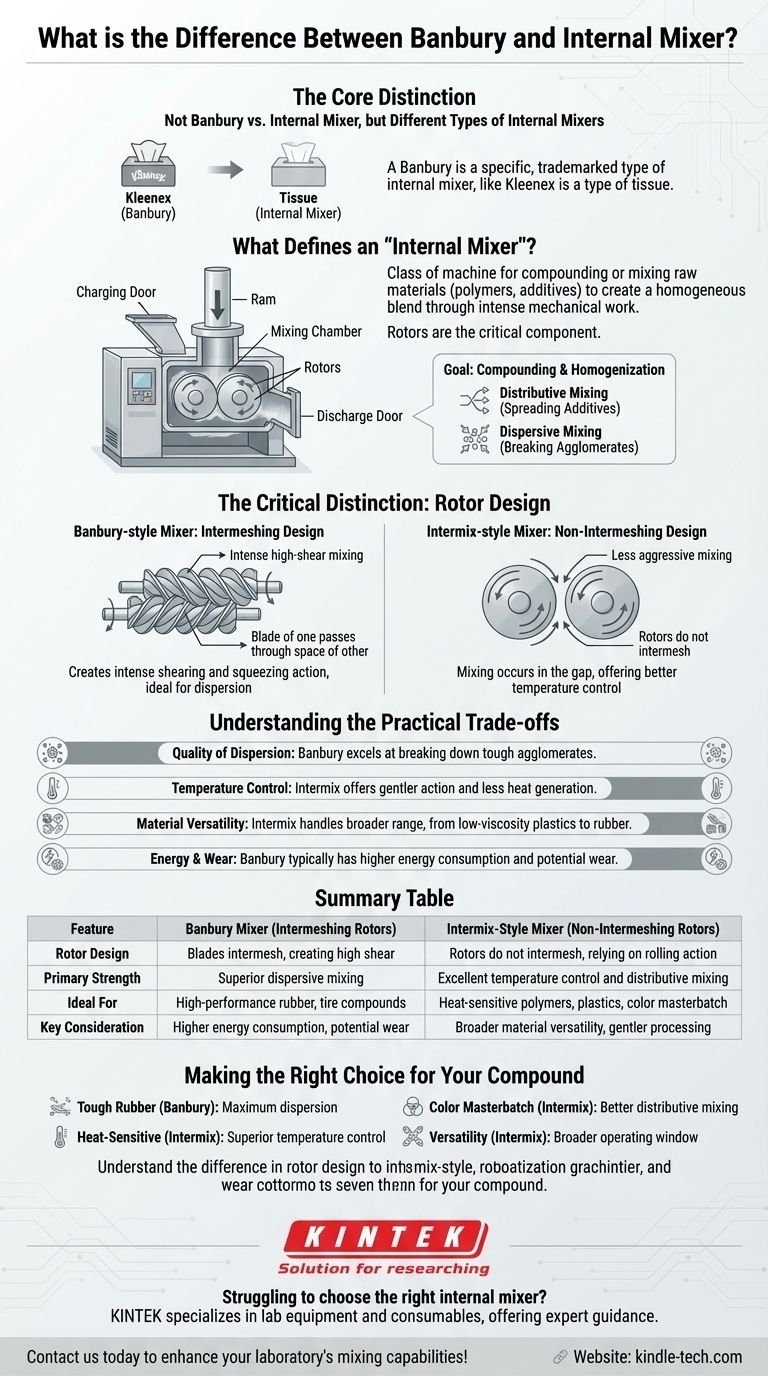

The core distinction is not between a Banbury and an internal mixer, but between different types of internal mixers. A Banbury mixer is a specific, trademarked type of internal mixer, much like a Kleenex is a type of tissue. The confusion arises because the term "internal mixer" is often used generically to refer to other designs, creating a false comparison.

The fundamental difference between internal mixer designs lies in their rotor configuration. A Banbury-style mixer uses intermeshing rotors that create intense, high-shear mixing, while an Intermix-style mixer uses non-intermeshing rotors that rely on a different shearing action, offering better temperature control.

What Defines an "Internal Mixer"?

An internal mixer is a class of machine designed for compounding or mixing raw materials, primarily polymers, with various additives. Its purpose is to create a homogeneous material blend through intense mechanical work.

The Core Components

All batch internal mixers share a common architecture: a fully enclosed mixing chamber, a charging door on top, a discharge door on the bottom, and a ram to keep pressure on the material.

The most critical components are the rotors, which are precision-engineered "blades" that rotate within the chamber to masticate and mix the material.

The Goal: Compounding and Homogenization

The primary function is to achieve two types of mixing:

- Distributive Mixing: Spreading additives evenly throughout the polymer matrix.

- Dispersive Mixing: Breaking down agglomerates of additives (like carbon black) into fine, individual particles.

The design of the rotors is what determines how effectively a mixer achieves these goals.

The Critical Distinction: Rotor Design

The real question is how a Banbury-style mixer's rotor design differs from other common internal mixer designs, such as the "Intermix." This difference dictates the machine's performance characteristics.

The Banbury Mixer: Intermeshing Design

The Banbury mixer, originally patented by Fernley H. Banbury, features two counter-rotating rotors with a complex, helical shape.

These rotors are intermeshing, meaning the blade of one rotor passes through the space between the blades of the opposing rotor.

This creates an intense shearing and squeezing action. The material is repeatedly forced through the small clearance between the rotor tips and the chamber wall, as well as between the rotors themselves, generating very high shear forces ideal for dispersion.

The "Intermix-style" Mixer: Non-Intermeshing Design

In this design, the two rotors also counter-rotate, but they do not intermesh. The distance between them remains constant.

The primary mixing action occurs in the gap between the rotors, creating a rolling bank of material. Shear is generated between the rotors and the chamber wall, but the rotor-to-rotor interaction is less aggressive than in a Banbury.

Understanding the Practical Trade-offs

The choice between an intermeshing (Banbury) and non-intermeshing (Intermix) design is a classic engineering trade-off. Each excels in different areas.

Quality of Dispersion

For materials that are difficult to disperse, like carbon black or silica in high-performance rubber compounds, the high-shear action of an intermeshing Banbury design is often superior. It excels at breaking down tough agglomerates.

Temperature Control

The intense mechanical work of a Banbury mixer generates significant heat. While this can be beneficial for some processes, it makes it challenging to mix temperature-sensitive materials that might scorch or degrade.

The gentler action of a non-intermeshing Intermix design generates less heat, providing a wider processing window and better temperature control for sensitive polymers and plastics.

Material Versatility

Because of its superior temperature control, the non-intermeshing design is often considered more versatile. It can effectively mix a broader range of materials, from low-viscosity plastics to medium-viscosity rubber compounds.

Energy Consumption and Wear

The high-stress, high-shear environment in a Banbury mixer typically leads to higher energy consumption and potentially more wear on the rotor tips and chamber walls over time compared to a non-intermeshing design under similar conditions.

Making the Right Choice for Your Compound

Selecting the correct mixer design is crucial for achieving the desired compound quality and process efficiency.

- If your primary focus is maximum dispersion for tough rubber compounds: The high-shear, intermeshing design of a Banbury mixer is the industry standard for applications like tires and industrial rubber goods.

- If your primary focus is mixing heat-sensitive polymers or plastics: The superior temperature control and gentler action of a non-intermeshing, Intermix-style mixer is the safer and more effective choice.

- If your primary focus is producing color masterbatch in plastic: A non-intermeshing design often provides better distributive mixing without degrading the polymer carrier or pigments.

- If your primary focus is versatility across a wide range of materials: A non-intermeshing mixer generally offers a broader and more forgiving operating window.

Ultimately, understanding the fundamental difference in rotor design empowers you to select the precise tool required for your specific material and processing goal.

Summary Table:

| Feature | Banbury Mixer (Intermeshing Rotors) | Intermix-Style Mixer (Non-Intermeshing Rotors) |

|---|---|---|

| Rotor Design | Blades intermesh, creating high shear | Rotors do not intermesh, relying on rolling action |

| Primary Strength | Superior dispersive mixing (breaks down tough agglomerates) | Excellent temperature control and distributive mixing |

| Ideal For | High-performance rubber, tire compounds | Heat-sensitive polymers, plastics, color masterbatch |

| Key Consideration | Higher energy consumption and potential wear | Broader material versatility and gentler processing |

Struggling to choose the right internal mixer for your lab's compounding needs? KINTEK specializes in lab equipment and consumables, offering expert guidance to help you select the perfect mixer—whether you require the high-shear dispersion of a Banbury-style design or the precise temperature control of a non-intermeshing model. Our solutions ensure optimal material homogeneity and process efficiency for your specific polymers and additives. Contact us today via our contact form to discuss your application and discover how KINTEK can enhance your laboratory's mixing capabilities!

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- What is the process of extrusion blowing? A Guide to Efficient Hollow Plastic Part Production

- What are the advantages of screw extruders? Achieve Efficient, Continuous Polymer Processing

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- Why is specific pressure applied during the cooling phase of UHMWPE processing? Ensuring Flatness and Structural Integrity

- What is the main purpose of vulcanization? Transform Rubber into a Durable, Elastic Material

- How profitable is injection molding? Unlock High-Volume Manufacturing Profitability

- What is a rubber milling machine? A Guide to Compounding vs. Grinding

- What are the disadvantages of twin screw? Higher Cost and Complexity vs. Single Screw