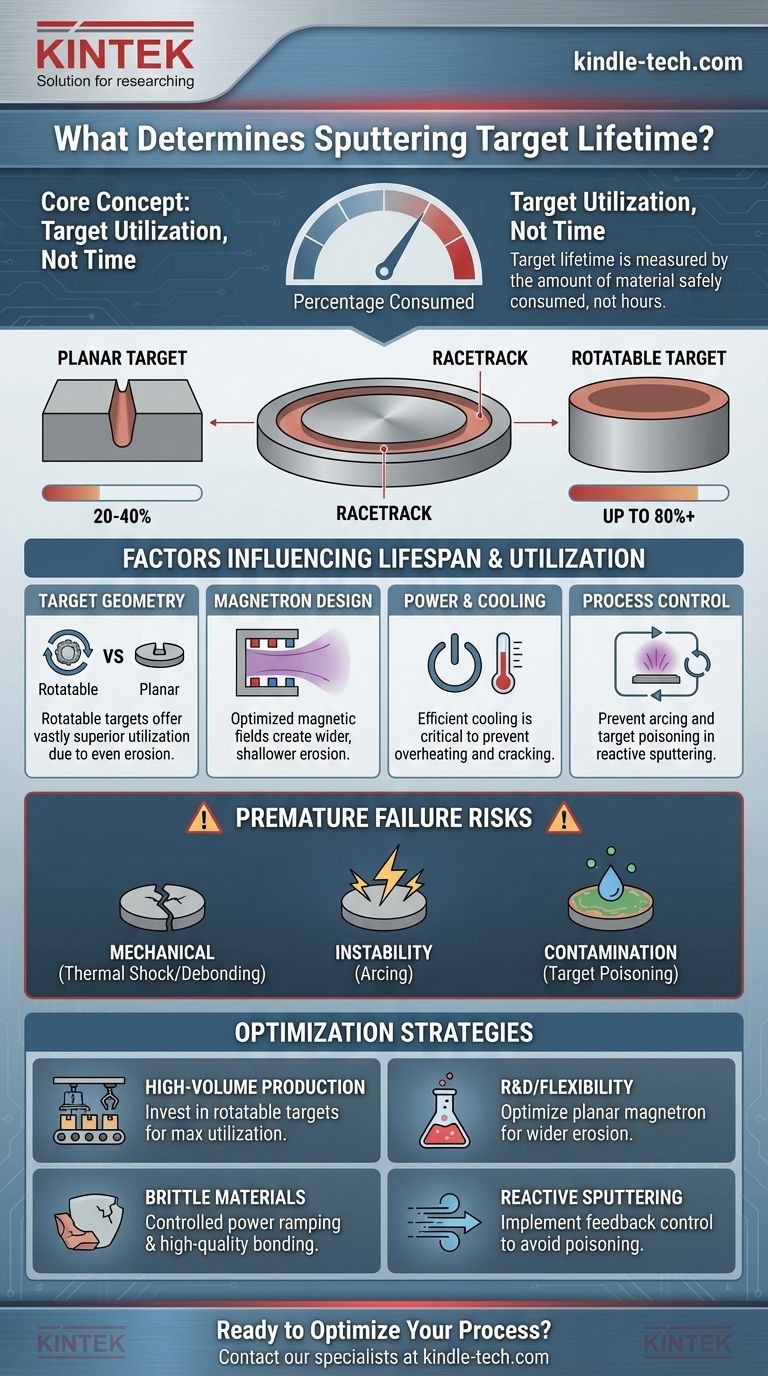

The lifetime of a sputtering target is not measured in hours or days, but by the amount of material that can be safely and effectively consumed. It is fundamentally determined by a metric called target utilization—the percentage of the target you can sputter away before it becomes unusable. This end-of-life point is typically reached when the thinnest point of the target approaches the backing plate, creating a risk of catastrophic system failure.

A sputtering target's life is over when the erosion of material becomes either unsafe or inefficient. Maximizing this lifespan is not about sputtering for as long as possible, but about maximizing the percentage of usable material while preventing premature failure from cracking, arcing, or poisoning.

The Primary Limiting Factor: Target Erosion

The core concept defining a target's lifespan is the physical erosion of its material. This process is not uniform across the target's surface.

The "Racetrack" Effect

In magnetron sputtering, magnets are positioned behind the target to trap electrons in a magnetic field close to the target surface.

This confinement dramatically increases the efficiency of ion generation, but it localizes the sputtering process to a specific area. This concentrated erosion creates a distinct groove known as the "racetrack."

Defining End-of-Life

The target's life is effectively over when the bottom of this racetrack groove gets dangerously close to the backing plate it is bonded to.

Sputtering completely through the target is a critical failure. It can cause cooling water to leak into the vacuum chamber, destroying the vacuum, contaminating the system, and potentially damaging other expensive components. Therefore, targets are always replaced before this can happen.

The Concept of Target Utilization

Target utilization is the most important metric for lifetime. It is the ratio of the volume of sputtered material to the initial total volume of the target.

For standard planar targets, utilization is often quite low, typically in the range of 20% to 40%. The majority of the material remains unused outside the deep erosion groove.

Factors That Determine Utilization and Lifespan

Several key factors in your sputtering system and process directly influence how much of the target you can actually use.

Target Geometry: Planar vs. Rotatable

The single biggest factor is the target's geometry. While planar targets are common, rotatable (or cylindrical) targets offer vastly superior utilization.

Because rotatable targets are cylindrical and rotate during sputtering, they erode much more evenly around their circumference. This eliminates the deep, localized "racetrack" of a planar target, allowing for utilization rates of up to 80% or more.

Magnetron Design

The design of the magnetron (the array of magnets behind the target) directly shapes the erosion profile.

An optimized magnetic field can spread the plasma more evenly, resulting in a wider and shallower racetrack. This directly increases material utilization and extends the usable life of a planar target.

Sputtering Power and Cooling

Higher sputtering power increases the deposition rate but also accelerates target erosion. More importantly, it generates more heat.

Efficient cooling is critical to prevent the target from overheating. The bond between the target material and the copper backing plate must ensure excellent thermal conductivity to draw this heat away effectively.

Understanding the Causes of Premature Failure

A target's life can be cut short by factors other than simple material depletion. These are common pitfalls that must be managed.

Mechanical Failure: Cracking and Debonding

Brittle materials, such as ceramics like Indium Tin Oxide (ITO), are highly susceptible to cracking from thermal shock. Ramping power up or down too quickly can create stress that fractures the target.

Poor bonding between the target material and the backing plate can also lead to failure. If the target debonds, thermal transfer is compromised, leading to overheating, cracking, or inconsistent sputtering.

Process Instability: Arcing

An arc is an uncontrolled, high-current electrical discharge on the target surface. It can be caused by surface contamination, dielectric nodules, or process instabilities.

Severe arcing can physically damage the target, creating pits or melting spots that disrupt the process and can even damage the power supply.

Chemical Contamination: Target Poisoning

In reactive sputtering, a reactive gas like oxygen or nitrogen is introduced to deposit a compound film (e.g., an oxide or nitride).

If the flow of reactive gas is too high relative to the sputtering rate, an insulating compound layer can form on the target surface itself. This is called "target poisoning," and it can drastically reduce or completely stop the sputtering process, rendering the target unusable until it is cleaned.

How to Apply This to Your Project

Maximizing target lifetime requires a clear understanding of your primary goal. Use these guidelines to inform your strategy.

- If your primary focus is cost-efficiency in high-volume production: Invest in a system that uses rotatable targets to achieve the highest possible material utilization.

- If your primary focus is R&D or process flexibility: Planar targets are suitable, but work on optimizing your magnetron design to create a wider, more uniform erosion profile.

- If your primary focus is sputtering brittle materials (e.g., ceramics): Prioritize controlled power ramping and ensure a high-quality bond to the backing plate to prevent cracking from thermal stress.

- If your primary focus is reactive sputtering: Implement a feedback control system to operate just shy of the "poisoned mode," maximizing your deposition rate without contaminating the target surface.

Ultimately, extending target lifetime is a function of controlling the interplay between your material, your hardware, and your process parameters.

Summary Table:

| Factor | Impact on Target Lifetime | Key Insight |

|---|---|---|

| Target Geometry | High | Rotatable targets offer up to 80% utilization vs. 20-40% for planar targets. |

| Magnetron Design | Medium | Optimized magnetic fields create wider, shallower erosion for longer life. |

| Sputtering Power & Cooling | Medium | Higher power accelerates erosion; efficient cooling prevents overheating and cracking. |

| Process Control | High | Prevents premature failure from arcing or target poisoning in reactive sputtering. |

Ready to Optimize Your Sputtering Process and Extend Target Lifespan?

Whether your priority is high-volume cost-efficiency with rotatable targets or precise R&D control with planar targets, KINTEK has the expertise and equipment to meet your laboratory's specific sputtering needs. Our specialists can help you select the right target geometry and optimize your process parameters to maximize material utilization and prevent premature failure.

Contact our team today to discuss how our lab equipment and consumables can enhance your deposition process's reliability and cost-effectiveness!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- Does pyrolysis require a catalyst? Unlock Higher-Value Fuels from Waste

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What is a sputter coater? A Guide to High-Precision Thin Film Deposition

- What is titanium used for in manufacturing? Leveraging High-Performance Properties for Critical Applications

- How does a mechanical propulsion system ensure HEA-NP quality? Master Fast Moving Bed Pyrolysis with Precision Control

- What is the heating rate in sintering? A Guide to Optimizing Your Thermal Cycle for Quality Parts

- What is the sputtering voltage of a magnetron? Optimize Your Thin Film Deposition Process