At its core, aluminum sputtering is a physical vapor deposition (PVD) process used to create an extremely thin and uniform coating of aluminum onto a surface, known as a substrate. Inside a vacuum chamber, a solid block of aluminum (the "target") is bombarded by high-energy ions from an inert gas, like argon. This atomic-scale collision physically knocks aluminum atoms off the target, which then travel and deposit onto the substrate, building up the desired film one atom at a time.

Sputtering is fundamentally a mechanical process, not a chemical or thermal one. It uses the kinetic energy of ion bombardment to physically dislodge atoms, granting precise control over the resulting film's thickness, density, and uniformity.

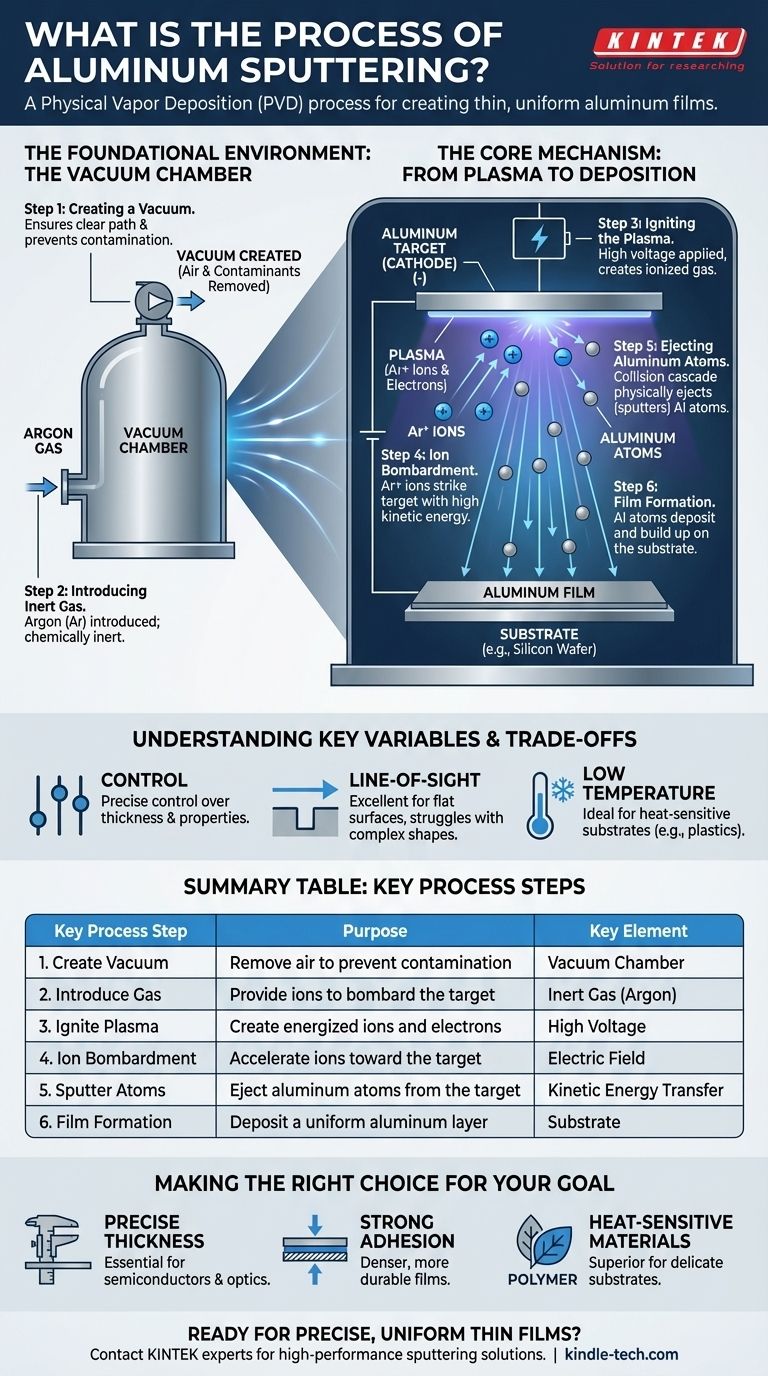

The Foundational Environment: The Vacuum Chamber

To understand the sputtering process, we must first understand the environment where it occurs. The entire operation takes place within a sealed vacuum chamber, which is critical for two reasons.

### Step 1: Creating a Vacuum

The chamber is first evacuated to remove air and other atmospheric gases. This prevents the sputtered aluminum atoms from colliding with unwanted particles, which would contaminate the film and disrupt its structure.

A high-quality vacuum ensures the aluminum atoms have a clear, unimpeded "line of sight" path from the target to the substrate.

### Step 2: Introducing an Inert Gas

Once the vacuum is established, a small, precisely controlled amount of an inert gas is introduced. Argon is the most common choice.

This gas is chosen because it is chemically inert, meaning it will not react with the aluminum. Its atoms also have sufficient mass to effectively dislodge aluminum atoms upon impact.

The Core Mechanism: From Plasma to Deposition

With the environment prepared, the active sputtering process can begin. This involves creating a plasma and using it as a medium to transfer energy.

### Step 3: Igniting the Plasma

A high voltage is applied across the chamber, with the aluminum target acting as the negative electrode (cathode). This strong electric field energizes the argon gas, stripping electrons from the argon atoms.

This process creates a glowing, energized state of matter called plasma, which is a mixture of positively charged argon ions (Ar+) and free electrons.

### Step 4: Ion Bombardment of the Target

The positively charged argon ions are forcefully accelerated by the electric field and drawn towards the negatively charged aluminum target at high velocity.

Think of this as a subatomic game of pool. The argon ions are the cue balls, and the aluminum target is the rack of balls. They strike the surface with immense kinetic energy.

### Step 5: Ejecting Aluminum Atoms

When an argon ion collides with the aluminum target, it transfers its momentum to the aluminum atoms. This sets off a collision cascade within the target's atomic structure.

If this cascade reaches the surface with enough energy to overcome the material's atomic binding force, one or more aluminum atoms are physically ejected, or "sputtered," from the target.

### Step 6: Film Formation on the Substrate

These newly freed, neutral aluminum atoms travel through the vacuum chamber. When they reach the substrate (such as a silicon wafer or piece of glass), they condense on its surface.

Over time, millions of these atoms arrive and stick to the substrate, building up a thin, dense, and highly uniform film of aluminum.

Understanding the Trade-offs and Key Variables

While powerful, the sputtering process is not without its complexities. The quality of the final film depends entirely on the precise control of several variables.

### Control Over Film Properties

The key advantage of sputtering is its control. By adjusting the voltage, the argon gas pressure, and the distance between the target and substrate, engineers can fine-tune the film's density, grain structure, and electrical properties.

### Sputtering is a Line-of-Sight Process

Sputtered atoms generally travel in straight lines. This means the process is excellent for coating flat surfaces but can struggle to uniformly coat complex, three-dimensional shapes with deep trenches or undercuts.

### A Mechanical, Not Thermal, Process

Unlike thermal evaporation where a material is melted, sputtering is a lower-temperature process driven by kinetic energy. This makes it ideal for coating heat-sensitive substrates, such as plastics, that would be damaged by high temperatures.

Making the Right Choice for Your Goal

Understanding the mechanics of aluminum sputtering allows you to determine if it is the appropriate technique for your specific application.

- If your primary focus is precise film thickness and uniformity: Sputtering offers exceptional, repeatable control over deposition rates, making it essential for applications in semiconductors and optics.

- If your primary focus is strong adhesion and film density: The high kinetic energy of the sputtered atoms creates denser, more durable films with better adhesion to the substrate compared to other methods.

- If your primary focus is coating heat-sensitive materials: Sputtering is a relatively cool process, making it the superior choice for depositing metal films onto polymers and other delicate substrates.

By mastering this process of controlled atomic transfer, we can design and manufacture materials with specific properties essential for modern technology.

Summary Table:

| Key Process Step | Purpose | Key Element |

|---|---|---|

| 1. Create Vacuum | Remove air to prevent contamination | Vacuum Chamber |

| 2. Introduce Gas | Provide ions to bombard the target | Inert Gas (Argon) |

| 3. Ignite Plasma | Create energized ions and electrons | High Voltage |

| 4. Ion Bombardment | Accelerate ions toward the target | Electric Field |

| 5. Sputter Atoms | Eject aluminum atoms from the target | Kinetic Energy Transfer |

| 6. Film Formation | Deposit a uniform aluminum layer | Substrate (e.g., Silicon Wafer) |

Ready to achieve precise, uniform thin films for your lab?

The aluminum sputtering process is key for applications in semiconductors, optics, and coating heat-sensitive materials. At KINTEK, we specialize in providing high-performance lab equipment, including sputtering systems, to help you master thin-film deposition with exceptional control over thickness, density, and adhesion.

Contact our experts today to discuss your specific needs and find the perfect sputtering solution for your laboratory.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the CVD process of silicon carbide? Achieve Unmatched Purity for Demanding Applications

- What are the drawbacks of chemical vapor deposition? Key Limitations to Consider Before Choosing CVD

- What is chemical vapor deposition in semiconductors? The Atomic-Scale Engine of Modern Electronics

- What is physical and chemical vapor deposition? A Guide to Choosing the Right Coating Technology

- What is CVD method? A Guide to Chemical Vapor Deposition for High-Performance Materials

- How does a CVD reaction furnace contribute to NCD coatings? Precision Synthesis for Diamond-Clad High-Performance Parts

- What is the thin film production method? A Guide to Deposition Techniques

- What is chemical vapor deposition process semiconductor? Building the Microscopic Layers of Modern Chips