At its core, sputtering is a physical vapor deposition (PVD) process used to create ultra-thin films of material on a surface. It functions by creating a plasma in a vacuum, accelerating ions from that plasma to strike a source material (the "target"), and knocking atoms off the target, which then travel and deposit onto the object being coated (the "substrate").

Sputtering is not a chemical reaction but a physical process of momentum transfer, much like a microscopic game of billiards. By controlling a vacuum environment and an energized plasma, you can precisely transport material, atom by atom, from a source target onto a substrate to form a high-purity, uniform coating.

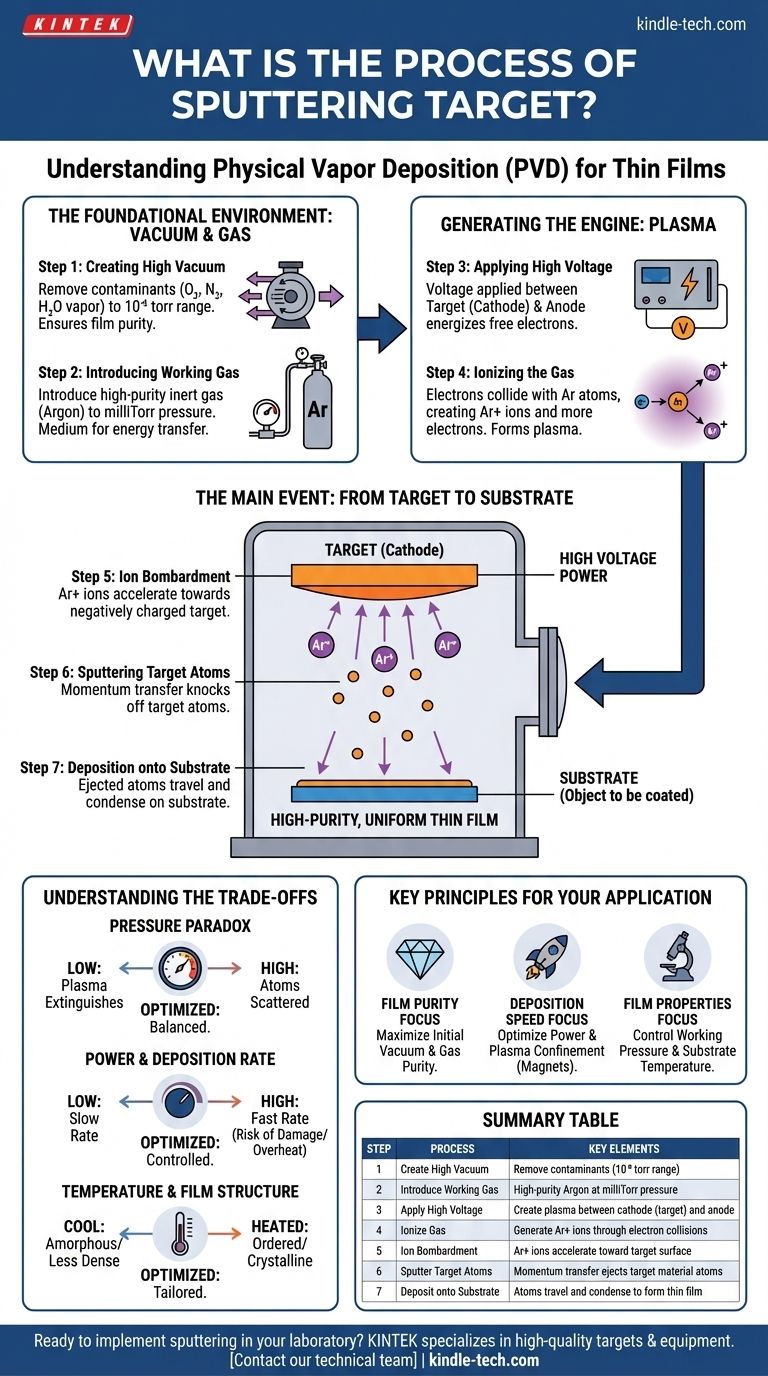

The Foundational Environment: Vacuum and Gas

To understand sputtering, you must first understand the pristine environment it requires. The entire process takes place inside a sealed chamber where every variable can be precisely controlled.

Step 1: Creating the Initial Vacuum

The first and most critical step is evacuating the chamber to a high vacuum, typically in the range of 10⁻⁶ torr. This is done to remove all residual gases like oxygen, nitrogen, and water vapor.

Failing to remove these contaminants would cause them to be incorporated into the thin film, compromising its purity, structure, and performance.

Step 2: Introducing the Working Gas

Once the chamber is clean, a high-purity inert gas—most commonly Argon—is introduced. The chamber pressure is carefully raised and stabilized at a low "working pressure," often in the milliTorr range.

Argon is used because its atoms are heavy enough to effectively sputter most materials, but as an inert gas, it will not chemically react with the target or the growing film. It serves only as the medium for transferring energy.

Generating the Engine of Sputtering: The Plasma

With the environment set, the next stage is to create the energized ions that will do the actual work of sputtering.

Step 3: Applying High Voltage to Create Plasma

A high voltage is applied between two electrodes inside the chamber. The target material itself is configured as the cathode (negative electrode), and the chamber walls or a separate anode serve as the positive electrode.

This voltage energizes free electrons naturally present in the gas, giving them the energy needed to initiate the plasma.

Step 4: Ionizing the Gas

The high-energy electrons collide with the neutral Argon atoms. These collisions are energetic enough to knock an electron off the Argon atom, resulting in two new particles: another free electron and a positively charged Argon ion (Ar+).

This chain reaction, called a glow discharge, quickly fills the chamber with a mixture of ions, electrons, and neutral atoms, which is the state of matter known as plasma. In many systems, magnets are placed behind the target to trap the electrons near its surface, dramatically increasing the number of collisions and creating a denser, more efficient plasma.

The Main Event: From Target to Substrate

This is where the physical transfer of material occurs. The plasma provides the ammunition, and the electric field provides the acceleration.

Step 5: Ion Bombardment

The positively charged Argon ions (Ar+) are strongly attracted and accelerated towards the negatively charged target. They strike the target surface with significant kinetic energy.

Step 6: Sputtering the Target Atoms

This collision is a pure momentum transfer event. When an Argon ion hits the target, it physically knocks out, or sputters, atoms from the target material. These ejected atoms fly off the target in various directions.

Step 7: Deposition onto the Substrate

The sputtered target atoms travel through the low-pressure vacuum chamber until they strike a surface. By strategically placing a substrate (the object to be coated) in the path of these atoms, they will land on it and condense.

Over time, this process builds up a thin, uniform, and highly pure film of the target material on the substrate's surface.

Understanding the Trade-offs

Sputtering is a highly controllable process, but it involves balancing competing factors to achieve the desired result.

The Pressure Paradox

A high initial vacuum is essential for purity, but a specific, low pressure of working gas is required to sustain the plasma. Controlling this working pressure is key; too low, and the plasma extinguishes, too high, and the sputtered atoms are scattered by gas collisions before they can reach the substrate, reducing deposition rate and film quality.

Power and Deposition Rate

The amount of power applied to the target directly correlates with the density of the plasma and the rate of ion bombardment. Increasing power will increase the deposition rate, but excessive power can damage the target or overheat the substrate, introducing stress into the film.

Temperature and Film Structure

The temperature of the substrate during deposition is a critical variable. A heated substrate can provide atoms with the energy to arrange themselves into a more ordered, crystalline structure. A cool substrate may result in an amorphous or less dense film.

Key Principles for Your Application

When considering sputtering, your specific goal will determine which process parameters are most important.

- If your primary focus is film purity: The quality of the initial vacuum and the purity of the sputtering gas are your most critical parameters.

- If your primary focus is deposition speed: The applied power and the efficiency of the plasma confinement (often via magnets) will be the dominant factors to optimize.

- If your primary focus is film properties (e.g., density, stress, or crystallinity): Controlling the working gas pressure and the substrate temperature is essential for manipulating the final film structure.

By mastering these fundamental principles, sputtering transforms from a series of steps into a powerful tool for engineering materials at the atomic level.

Summary Table:

| Step | Process | Key Elements |

|---|---|---|

| 1 | Create High Vacuum | Remove contaminants (10⁻⁶ torr range) |

| 2 | Introduce Working Gas | High-purity Argon at milliTorr pressure |

| 3 | Apply High Voltage | Create plasma between cathode (target) and anode |

| 4 | Ionize Gas | Generate Ar+ ions through electron collisions |

| 5 | Ion Bombardment | Ar+ ions accelerate toward target surface |

| 6 | Sputter Target Atoms | Momentum transfer ejects target material atoms |

| 7 | Deposit onto Substrate | Atoms travel and condense to form thin film |

Ready to implement sputtering in your laboratory? KINTEK specializes in high-quality sputtering targets and lab equipment for precise thin film deposition. Whether you're working on semiconductor fabrication, optical coatings, or materials research, our experts can help you select the right targets and optimize your sputtering parameters for superior film purity and performance. Contact our technical team today to discuss your specific application requirements and discover how KINTEK's solutions can enhance your research and production outcomes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What products are made using laser sintering? From Medical Implants to Aerospace Parts

- What is the function of a constant temperature magnetic stirrer in the synthesis of SO3H-functionalized ionic liquids?

- How does a rotary vacuum evaporator work? A Guide to Gentle, Efficient Solvent Removal

- What is pyrolysis conversion of biomass? Unlock the Potential of Waste-to-Energy Technology

- How does sintering work? A Guide to Atomic Bonding and Material Densification

- What is the two step sintering method? Achieve High Density with Fine Grain Structure

- What is e-beam used for? A High-Speed, Non-Thermal Solution for Sterilization & Material Enhancement

- What is called sputtering? The Ultimate Guide to High-Quality Thin Film Deposition