A rotary vacuum pump is a foundational tool used to create a low-pressure environment, often called a "rough vacuum." It is widely employed in scientific research, laboratory applications, and various industrial processes where removing air and other gases from a sealed space is necessary. These pumps are valued for their reliability and cost-effectiveness in achieving moderate vacuum levels.

The primary purpose of a rotary vacuum pump is to mechanically displace gas molecules from a sealed chamber. It operates on a principle of positive displacement, using rotating parts to trap, compress, and exhaust gas, making it a workhorse for applications that require a rough vacuum, such as in labs with aqueous samples or high-boiling solvents.

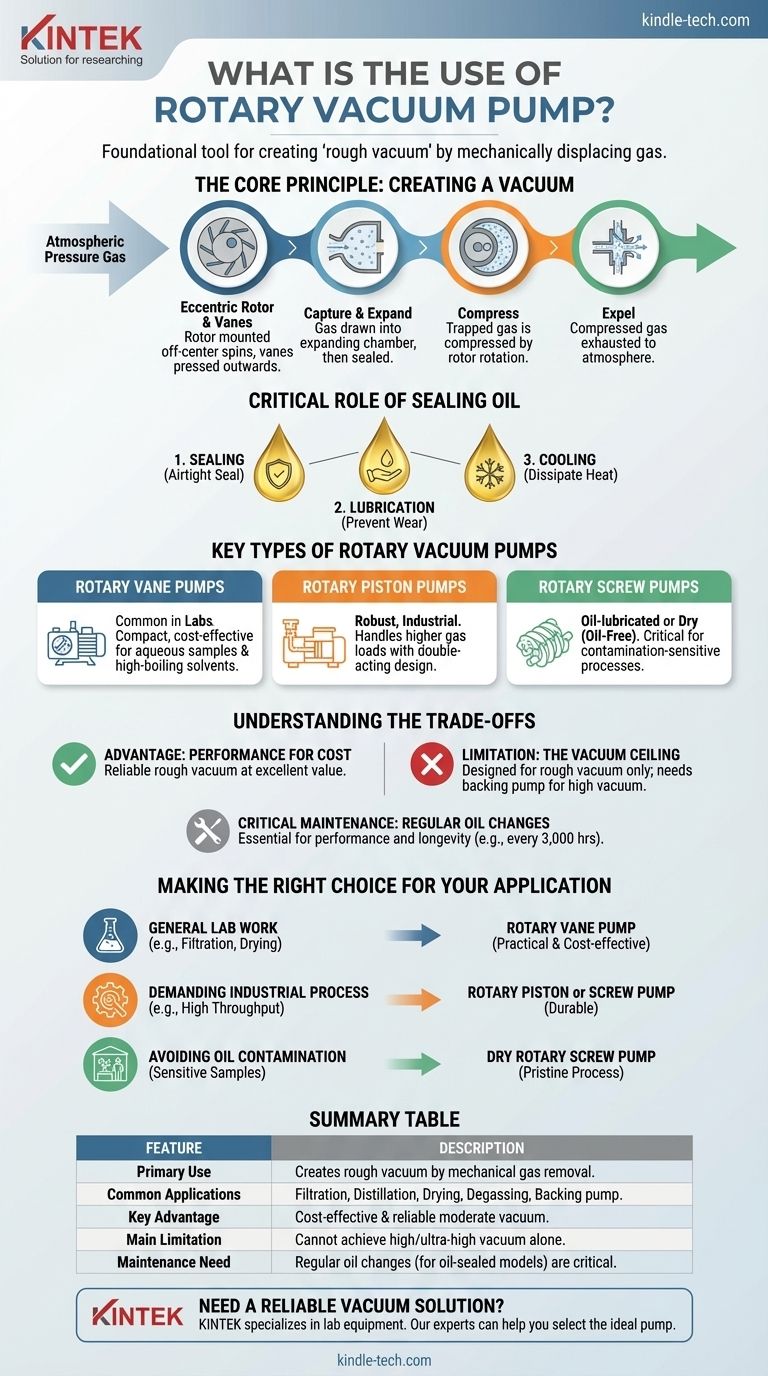

The Core Principle: How a Rotary Pump Creates a Vacuum

Understanding how a rotary pump works reveals its strengths and limitations. The mechanism is a clever application of simple mechanical principles to manipulate gas pressure.

The Eccentric Rotor

At the heart of the pump is a rotor that is mounted eccentrically (off-center) inside a cylindrical housing, known as the stator. This off-center placement is the key to its entire operation.

Capturing and Compressing Gas

As the rotor spins, vanes housed within it are thrown outwards by centrifugal force, pressing against the inner wall of the housing. This action divides the space into chambers of continuously changing volume.

Gas from the inlet port is drawn into a chamber as it expands. As the rotor continues to turn, that chamber is sealed off and begins to shrink, compressing the trapped gas.

Expelling the Gas

Once the trapped gas is compressed to a pressure slightly above the external atmospheric pressure, it is forced out through an exhaust valve. This cycle repeats rapidly, continuously removing gas from the system and lowering the pressure.

The Critical Role of Sealing Oil

Most rotary pumps are "wet" or oil-sealed. A special low-vapor-pressure oil is used for three critical functions:

- Sealing: It creates an airtight seal between the moving vanes and the housing.

- Lubrication: It lubricates all moving parts to prevent wear.

- Cooling: It helps dissipate the heat generated by gas compression.

Key Types of Rotary Vacuum Pumps

While they share a common principle, rotary pumps come in several designs, each suited for different tasks.

Rotary Vane Pumps

This is the most common type found in laboratories. They are compact, relatively inexpensive, and highly effective for creating a rough vacuum for applications involving aqueous samples and high-boiling solvents.

Rotary Piston Pumps

These are more robust, often used in demanding industrial applications. They use an eccentric rotor and a slide valve in a double-acting design, allowing them to handle higher gas loads.

Rotary Screw Pumps

This design uses two parallel, interlocking screw-shaped rotors. As they rotate, they trap gas between their threads and transport it to the exhaust. A key advantage is that they are available in both oil-lubricated and dry (oil-free) versions, which is critical for processes sensitive to contamination.

Understanding the Trade-offs

No single technology is perfect. A rotary pump's value is defined by its balance of performance, cost, and maintenance requirements.

Advantage: Performance for the Cost

Rotary pumps offer excellent vacuum performance for their price point. They are the go-to solution for achieving rough vacuum levels reliably and efficiently without the expense of more advanced pump technologies.

Limitation: The Vacuum Ceiling

These pumps are designed for rough vacuum. They cannot, by themselves, achieve the "high" or "ultra-high" vacuum levels required for applications like particle accelerators or semiconductor manufacturing. They are often used as a "backing pump" to create the initial low pressure needed for a high-vacuum pump to take over.

The Critical Need for Maintenance

For oil-sealed pumps, the oil is both their greatest asset and their primary point of failure. It must be checked and changed regularly (e.g., every 3,000 hours of use). Contaminated or degraded oil will compromise the vacuum level and can quickly destroy the pump.

Making the Right Choice for Your Application

Selecting the correct pump depends entirely on the demands of your specific process.

- If your primary focus is general laboratory work: A standard rotary vane pump is likely the most practical and cost-effective choice for tasks like vacuum filtration, drying, or distillation.

- If your primary focus is a demanding industrial process: A more robust rotary piston or rotary screw pump will provide the durability needed for continuous operation and higher gas throughput.

- If your primary focus is avoiding oil contamination: A dry rotary screw pump is the only suitable option, ensuring your process or sample remains pristine.

Ultimately, understanding the mechanics of a rotary vacuum pump allows you to leverage it as a reliable and powerful tool for your specific goals.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | Creates a rough vacuum by mechanically removing gas from a sealed chamber. |

| Common Applications | Vacuum filtration, distillation, drying, degassing, and as a backing pump for high-vacuum systems. |

| Key Advantage | Cost-effective and reliable performance for achieving moderate vacuum levels. |

| Main Limitation | Designed for rough vacuum; cannot achieve high or ultra-high vacuum alone. |

| Maintenance Need | Regular oil changes (for oil-sealed models) are critical for performance and longevity. |

Need a reliable vacuum solution for your lab?

KINTEK specializes in lab equipment and consumables, offering a range of rotary vacuum pumps tailored to your specific needs—whether for general laboratory work, demanding industrial processes, or contamination-sensitive applications. Our experts can help you select the ideal pump to enhance your efficiency and ensure reliable performance.

Contact KINTEK today to find the perfect vacuum pump for your laboratory!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- Which of the following are methods used to deposit thin films? A Guide to PVD, CVD & More

- What happens during sintering of ceramics? A Guide to Transforming Powder into Dense, Strong Parts

- What kinds of components are produced through the sintering process? Essential Parts for High-Performance Industries

- How do you test for CVD diamonds? Uncover the scientific methods for definitive identification.

- What are the process advantages of combining high-speed shear systems with chemical catalysts? Maximize Biomass Yield

- What are the disadvantages of using graphite? Key Limitations in High-Tech Applications

- What is the physical sputtering method? A Guide to High-Performance Thin Film Deposition

- What are the different types of pyrolysis waste to energy? A Guide to Bio-char, Bio-oil, and Syngas Production