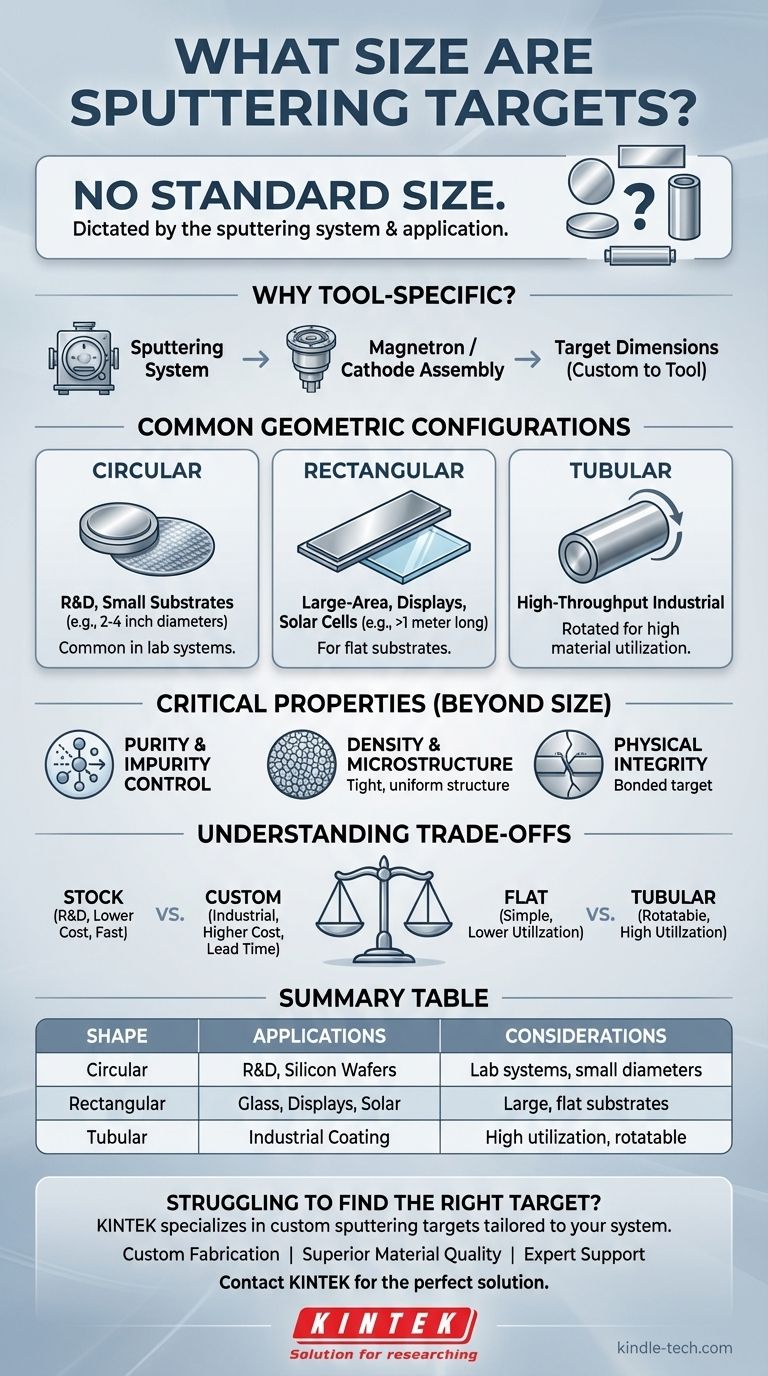

The short answer is there is no standard size. Sputtering targets are manufactured in a wide variety of shapes and sizes because their dimensions are determined entirely by the design of the specific sputtering system they are used in. Common configurations include circular, rectangular, and tubular (cylindrical) forms, ranging from small discs for research to large plates for industrial production.

The critical insight is that a sputtering target's size and shape are not independent variables; they are dictated by the sputtering tool's design and the intended application. Therefore, the focus should not be on finding a "standard" size, but on understanding the requirements of a specific system.

Why Target Dimensions are Tool-Specific

The geometry of a sputtering target is fundamentally linked to the architecture of the deposition chamber and the process goals. The manufacturer of the sputtering equipment specifies the exact dimensions required for proper function.

The Role of the Sputtering System

Every sputtering system, from a small lab-scale coater to a massive industrial machine, has a component called a magnetron or cathode assembly where the target is mounted. The size of this assembly directly determines the required size of the target.

This assembly is responsible for both holding the target and, in most cases, providing water cooling via a bonded backing plate.

Common Geometric Configurations

While sizes are custom, targets generally fall into a few common shapes, each suited for different applications.

- Circular Targets: These are very common in research and development (R&D) systems due to their efficiency in coating smaller, uniform substrates like silicon wafers. Diameters of 2-4 inches are typical for lab settings.

- Rectangular Targets: Used for coating large, flat substrates uniformly. Think of applications like architectural glass, flat-panel displays, or solar cells, where targets can be over a meter long.

- Tubular/Cylindrical Targets: These are used in high-throughput, in-line industrial systems. They can be rotated during sputtering, leading to very high material utilization and long operational lifetimes.

Beyond Size: The Critical Properties of a Target

Focusing solely on size misses the most important aspects of a sputtering target. The quality and characteristics of the target material itself have a far greater impact on the final thin film.

Purity and Impurity Control

The purity of the target material is paramount. Any impurities or contaminants present in the target will be sputtered along with the desired material, becoming incorporated into the deposited film and potentially ruining its electrical, optical, or mechanical properties.

Density and Microstructure

A high-density target with a uniform, fine-grained microstructure is essential. Low-density targets with voids can cause process instability and defects in the film. A consistent grain size ensures a stable and predictable sputtering rate over the target's life.

Physical Integrity

Targets must be free of cracks or voids. They are typically bonded to a metallic backing plate (often copper) which provides mechanical support and facilitates heat removal. A poor bond or cracked target can lead to overheating and catastrophic failure during the process.

Understanding the Trade-offs

The choice of target geometry involves balancing cost, efficiency, and application requirements.

Stock vs. Custom Dimensions

Targets for common R&D systems (e.g., 2-inch or 3-inch circular) are often available as stock items, making them relatively inexpensive and quick to procure.

Conversely, large or uniquely shaped targets for specialized industrial equipment are custom-fabricated, leading to significantly higher costs and longer lead times.

Target Shape and Material Utilization

Different shapes offer different levels of efficiency. Flat targets (circular and rectangular) are simpler and cheaper to manufacture.

However, tubular or ring-shaped targets, while more expensive, can offer much higher material utilization because they can be rotated, exposing fresh material and avoiding the deep "racetrack" erosion pattern common in flat magnetron targets.

Making the Right Choice for Your Goal

Selecting a target begins and ends with the specifications of your deposition system.

- If your primary focus is R&D: You will most likely use small, common circular targets defined by your lab-scale coater's manufacturer.

- If your primary focus is large-area industrial coating: Your system will demand large rectangular or tubular targets with precise, custom dimensions.

- If your primary focus is process reliability: You must prioritize material quality—high purity, high density, and uniform microstructure—above all other factors.

Ultimately, the right target is the one that meets the exact physical specifications of your equipment and the stringent material quality demands of your application.

Summary Table:

| Common Target Shape | Typical Applications | Key Considerations |

|---|---|---|

| Circular | R&D, Coating Silicon Wafers | Common in lab systems (e.g., 2-4 inch diameters) |

| Rectangular | Architectural Glass, Displays, Solar Cells | Used for large, flat substrates; can be over a meter long |

| Tubular/Cylindrical | High-Throughput Industrial Coating | High material utilization; rotated during use |

Struggling to find the right sputtering target for your specific equipment?

At KINTEK, we specialize in manufacturing high-quality lab equipment and consumables, including custom sputtering targets tailored to your system's exact specifications. We understand that the right target is critical for process reliability and film quality.

We provide:

- Custom Fabrication: Targets in circular, rectangular, or tubular shapes to fit your tool.

- Superior Material Quality: High-purity, high-density targets with uniform microstructure for consistent performance.

- Expert Support: Guidance to ensure compatibility and optimal results for your R&D or production needs.

Don't let target specifications slow down your research or production. Contact KINTEK today for a consultation and let our experts help you secure the perfect sputtering solution.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition