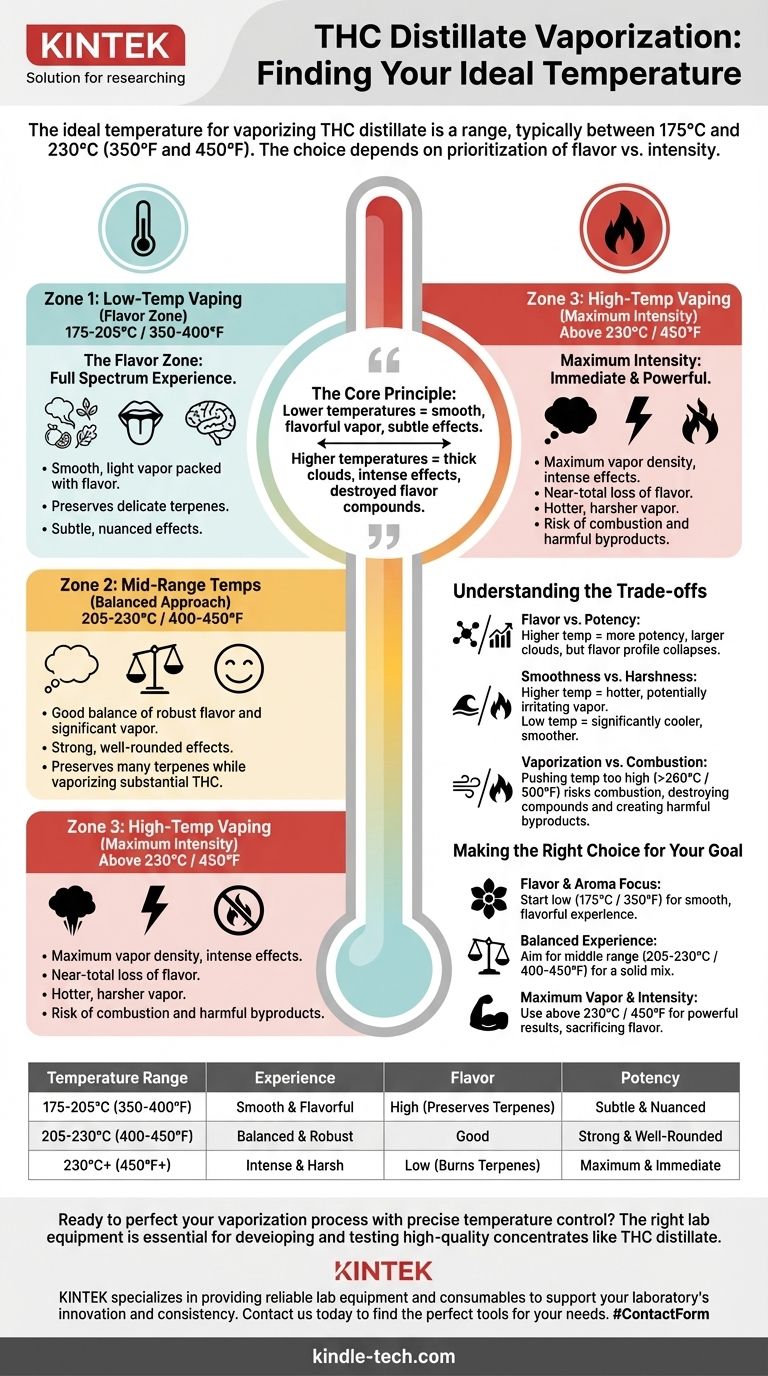

The ideal temperature for vaporizing THC distillate is not a single number, but a range. While THC's scientific boiling point is 157°C (315°F), the effective temperature for a satisfying experience in a vaporizer or dab rig is typically between 175°C and 230°C (350°F and 450°F). Choosing a temperature within this range depends entirely on whether you want to prioritize flavor or intensity.

The core principle is a trade-off: lower temperatures produce smooth, flavorful vapor with more subtle effects, while higher temperatures produce thick clouds and intense effects at the cost of destroying delicate flavor compounds.

Why Temperature Is a Crucial Tool

Understanding vaporization requires looking beyond a single boiling point. The process is about carefully releasing a spectrum of compounds, each with its own unique properties and vaporization temperature.

The Boiling Point vs. The Vaping Range

The scientifically cited boiling point of THC (157°C / 315°F) is the minimum temperature at which it will turn into a gas under a vacuum. In practice, you need more heat energy to produce a dense, satisfying vapor cloud quickly.

This is why the effective vaping range starts higher, ensuring the concentrate vaporizes efficiently on contact with the heated surface.

How Distillate is Different

THC distillate is a highly refined concentrate, often reaching over 90% purity. The refinement process strips away almost everything else, including the terpenes—the aromatic compounds responsible for the cannabis plant's distinct smells and flavors.

Producers often reintroduce specific terpenes to create a desired flavor profile. These reintroduced terpenes are extremely volatile and sensitive to heat, making precise temperature control even more important.

Finding Your Ideal Temperature Range

Your goal dictates the ideal temperature. The experience can be broken down into three main zones, each offering a distinct balance of flavor and effect.

Low-Temp Vaping (175-205°C / 350-400°F): The Flavor Zone

This range is for users who want to experience the full spectrum of the added terpenes. The vapor will be smoother, lighter, and packed with flavor.

The effects may feel more nuanced and less overwhelming, as you are vaporizing the terpenes without instantly scorching them.

Mid-Range Temps (205-230°C / 400-450°F): The Balanced Approach

This is the most common "sweet spot" for the majority of users. It provides an excellent balance between robust flavor and significant vapor production.

You still preserve many of the terpenes while ensuring you are vaporizing a substantial amount of THC for a potent, well-rounded effect.

High-Temp Vaping (Above 230°C / 450°F): Maximum Intensity

This range maximizes vapor density and delivers the most immediate and intense effects. The trade-off is a near-total loss of flavor, as the high heat instantly destroys the delicate terpenes.

The vapor will be noticeably hotter and harsher. Pushing temperatures too high in this zone also increases the risk of combustion.

Understanding the Trade-offs

Choosing a temperature is an act of balancing competing priorities. Being aware of the compromises is key to finding what works for you.

Flavor vs. Potency

This is the primary trade-off. As you increase the temperature, the perceived potency and cloud size increase dramatically. At the same time, the nuanced flavor profile collapses.

Smoothness vs. Harshness

Higher temperatures create hotter vapor, which can be irritating to the throat and lungs. Low-temperature vapor is significantly cooler and smoother, allowing for a more comfortable experience.

Vaporization vs. Combustion

Pushing temperatures too high—especially above 260°C (500°F)—risks combustion. Burning the distillate, rather than vaporizing it, destroys the very compounds you seek to inhale and can create harmful byproducts like benzene. Efficient vaporization is always the goal.

Making the Right Choice for Your Goal

Experimenting with your device is the best way to find your personal preference. Use these guidelines as a starting point for your exploration.

- If your primary focus is flavor and aroma: Begin at the lowest setting (around 175°C / 350°F) to preserve the delicate terpenes and enjoy a smooth experience.

- If your primary focus is a balanced experience: Aim for the middle range (205-230°C / 400-450°F) to get a solid mix of good flavor and strong effects.

- If your primary focus is maximum vapor and intensity: Use temperatures above 230°C / 450°F, but know that you will sacrifice all flavor for immediate, powerful results.

Ultimately, mastering temperature gives you direct control over tailoring your cannabis experience.

Summary Table:

| Temperature Range | Experience | Flavor | Potency |

|---|---|---|---|

| 175-205°C (350-400°F) | Smooth & Flavorful | High (Preserves Terpenes) | Subtle & Nuanced |

| 205-230°C (400-450°F) | Balanced & Robust | Good | Strong & Well-Rounded |

| 230°C+ (450°F+) | Intense & Harsh | Low (Burns Terpenes) | Maximum & Immediate |

Ready to perfect your vaporization process with precise temperature control? The right lab equipment is essential for developing and testing high-quality concentrates like THC distillate. KINTEK specializes in providing reliable lab equipment and consumables to support your laboratory's innovation and consistency. Contact us today using the form below to find the perfect tools for your needs.

Visual Guide

Related Products

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization

- What tools are used for battery research and material processing? Enhance Your Lab's Material Prep with KINTEK

- What type of instruments Cannot be autoclaved? Protect Your Equipment from Heat and Moisture Damage

- What is the significance of using an ultrasonic homogenizer to treat cells on NCD films? Optimize Protein Extraction

- What is grinder in chemistry? A Guide to Precision Sample Preparation