To be clear, the distillation of THC occurs within a specific range, but a single number is misleading. For the main THC fraction, the boiling flask (or evaporator) temperature is typically set between 180°C and 200°C (356°F - 392°F). However, this temperature is entirely dependent on achieving a deep and stable vacuum.

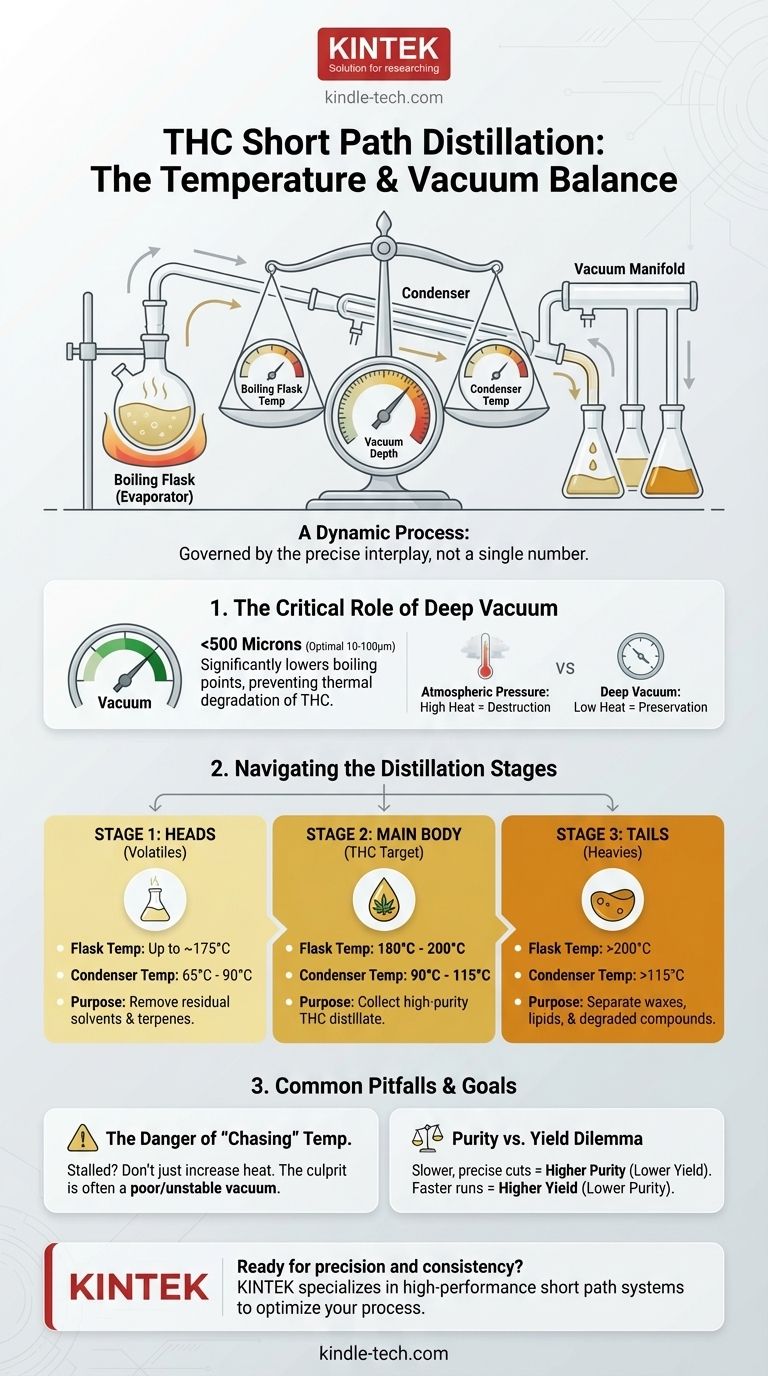

The critical insight is that short path distillation is not about a single temperature setting. It is a dynamic process governed by the precise interplay between three factors: boiling flask temperature, condenser temperature, and most importantly, the depth of your vacuum.

The Principles of Short Path Distillation

Short path distillation is the industry standard for producing high-purity cannabis distillate. Its primary purpose is to separate cannabinoids like THC from less desirable compounds such as terpenes, fats, waxes, and chlorophyll.

The Critical Role of Deep Vacuum

The entire process hinges on the vacuum. Cannabinoids are heavy molecules with very high boiling points—so high that they would be destroyed by heat at normal atmospheric pressure.

A deep vacuum dramatically lowers the boiling point of all compounds in the crude oil. This allows you to distill THC at a much lower, non-destructive temperature, preserving its integrity.

For effective cannabinoid distillation, a vacuum level below 500 microns is required, with optimal results often achieved between 10 and 100 microns.

Understanding the Key Temperature Zones

In a short path system, you are controlling multiple temperatures simultaneously to carefully separate different chemical "fractions."

Boiling Flask (Evaporator) Temperature

This is the heat applied to your crude oil via a heating mantle. It provides the energy needed to vaporize the target compounds. If the temperature is too low, the distillation will stall. If it's too high, you risk thermal degradation of THC into CBN, reducing potency and value.

Condenser Temperature

The condenser acts as a temperature-controlled gate. As vapor rises from the boiling flask, it hits the cooler condenser coils. By setting the condenser temperature precisely, you can choose which compounds condense back into a liquid (for collection) and which remain as a vapor to be pulled away by the vacuum.

Cold Trap Temperature

This isn't for fractionation but for protection. The cold trap, typically chilled with dry ice and acetone or liquid nitrogen, condenses any remaining volatile vapors before they can enter and damage your expensive vacuum pump.

Navigating a Typical Distillation Run

A distillation run is performed in stages, collecting different fractions by carefully manipulating the temperatures.

The "Heads" Fraction

This is the first fraction you collect. It contains the most volatile compounds like residual solvents and some terpenes.

- Boiling Flask Temp: Gradually increase from ambient to ~175°C.

- Condenser Temp: Typically set between 65°C and 90°C.

The "Main Body" (THC) Fraction

This is your target fraction—the high-purity, golden THC distillate.

- Boiling Flask Temp: Increase to the 180°C - 200°C range.

- Condenser Temp: Increase to 90°C - 115°C to effectively condense the THC vapor.

The "Tails" Fraction

This final fraction contains heavier, less desirable compounds like waxes, lipids, and degraded cannabinoids (CBN).

- Boiling Flask Temp: Increase to >200°C.

- Condenser Temp: Often raised significantly higher to allow these compounds to pass through to a separate collection flask.

Common Pitfalls and Trade-offs

Success in distillation comes from understanding the process, not just following a recipe.

The Purity vs. Yield Dilemma

The speed of your distillation and the precision of your temperature "cuts" between fractions determine your final product. A slower, more careful separation with narrow temperature windows results in higher purity but a lower overall yield. A faster run with wider windows increases yield but sacrifices purity.

The Danger of "Chasing" Temperature

A common mistake is to keep increasing the heating mantle temperature when the distillation stalls. The true culprit is almost always a poor or unstable vacuum. Cranking up the heat in this scenario will only "scorch" your oil and degrade the THC.

Importance of Decarboxylation

Your crude oil must be fully decarboxylated before it enters the distillation unit. Any remaining acidic cannabinoids (like THCA) will not distill properly and can cause pressure issues within the system, compromising the process.

Making the Right Choice for Your Goal

The optimal parameters depend entirely on your desired outcome.

- If your primary focus is maximum purity: Use a very deep, stable vacuum (<50 microns) and make slow, precise adjustments to temperature, collecting a very narrow "main body" fraction.

- If your primary focus is maximum yield: You can use slightly wider temperature windows for your collection flasks, accepting that some "heads" and "tails" will mix into your main body, slightly lowering its purity.

- If your primary focus is consistency and safety: Prioritize achieving a deep, stable vacuum before you begin applying significant heat. A stable system is a predictable and safe system.

Mastering distillation is about learning to balance these variables to achieve your specific goal.

Summary Table:

| Process Stage | Boiling Flask Temp | Condenser Temp | Purpose |

|---|---|---|---|

| Heads Fraction | Up to ~175°C | 65°C - 90°C | Remove volatile solvents & terpenes |

| Main Body (THC) Fraction | 180°C - 200°C | 90°C - 115°C | Collect high-purity THC distillate |

| Tails Fraction | >200°C | >115°C | Separate heavier waxes and lipids |

Ready to achieve high-purity THC distillate with precision and consistency? The right lab equipment is critical for controlling the delicate balance of temperature and vacuum. KINTEK specializes in high-performance short path distillation systems and lab equipment, helping laboratories optimize their processes for maximum yield and purity. Contact our experts today to find the perfect solution for your cannabis extraction and purification needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the advantage of an e-beam evaporator over a filament evaporator? Achieve Higher Purity & Precision

- What role does the sintering process play in TiO2 photocatalysts? Optimize Adhesion and Phase Transition

- What is the degree of calcination? Achieve Optimal Thermal Processing for Your Materials

- Why is biochar controversial? Balancing Climate Promise with Real-World Risks

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What are the requirements for polymer foam templates for reticulated MAX phase ceramics? Ensure Structural Integrity

- Why is the use of a high-temperature drying oven necessary for aluminum sludge recycling? Ensure Data Precision

- What is the fundamental of physical vapor deposition? A Guide to High-Performance Thin Films