Sputter yield in an ion beam system is determined by four primary factors: the energy of the incoming ions, the mass of the ions, the angle at which they strike the target, and the physical properties of the target material itself. These parameters collectively govern the efficiency of the momentum transfer that causes atoms to be ejected from the target surface.

The core principle of sputtering is a physical collision process. To control the sputter yield, you must control the transfer of kinetic energy from the incident ion to the target atoms, balancing the force of the impact against the risk of simply burying the ion deep within the target.

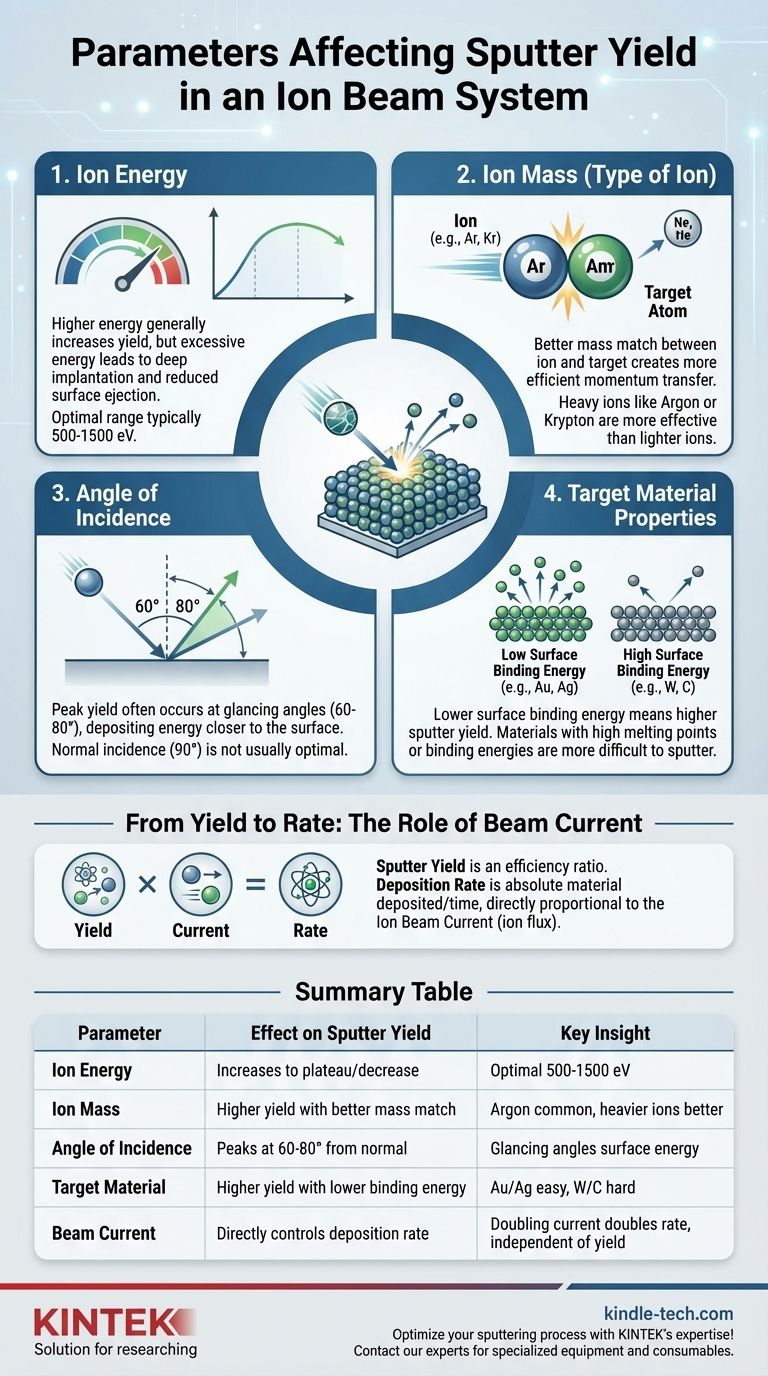

The Core Parameters Governing Sputter Yield

Understanding how each parameter influences the sputtering process is key to optimizing your results, whether your goal is maximum deposition rate or precise film quality.

Ion Energy

The kinetic energy of the incoming ions is a primary driver of sputter yield. As ion energy increases, the sputter yield generally rises because each ion has more energy to transfer upon impact, creating a larger collision cascade within the target.

However, this relationship is not linear. Above a certain energy threshold (typically in the range of a few to tens of keV), the yield begins to plateau or even decrease. This is because very high-energy ions penetrate deeper into the target, dissipating their energy far below the surface, which makes it less likely for an atom to be ejected.

Ion Mass (Type of Ion)

The mass of the sputtering gas ion relative to the target atom's mass is critical. A better mass match between the ion and the target atom results in more efficient momentum transfer and a higher sputter yield.

Think of it like billiards: a heavy ion (like Argon or Krypton) striking a target is like a bowling ball hitting pins. A light ion (like Neon or Helium) is like a tennis ball; it will transfer less momentum and likely just bounce off or implant. For this reason, Argon is a common and effective choice for many materials.

Angle of Incidence

The angle at which the ion beam strikes the target has a significant impact on yield. For most materials, the sputter yield is not highest at a normal incidence (90 degrees).

Instead, the yield typically peaks at an off-normal angle, often between 60 and 80 degrees from the surface normal. At these glancing angles, the ion's energy is deposited closer to the surface, increasing the probability that the resulting collision cascade will eject an atom. At very shallow angles, the ion is more likely to simply reflect off the surface.

Target Material Properties

The sputter yield is intrinsically tied to the target material itself, specifically its surface binding energy. This is the energy required to remove an atom from the surface.

Materials with lower surface binding energies (like gold, silver, or copper) will have a higher sputter yield under the same conditions. Conversely, materials with very high binding energies or high melting points (like tungsten, molybdenum, or carbon) are much more difficult to sputter and have a lower yield.

From Yield to Rate: The Role of Beam Current

While the parameters above define the yield (atoms per ion), the practical goal is often to control the deposition rate (film thickness per unit time). This is where ion beam current becomes the dominant factor.

Distinguishing Yield from Rate

It is crucial to separate these two concepts. Sputter Yield is an efficiency ratio: the number of target atoms ejected for every single incident ion. Deposition Rate is an absolute measure of material deposited over time.

The Impact of Ion Beam Current

The ion beam current is a measure of the number of ions hitting the target per second (ion flux). Therefore, the overall material removal rate is a direct product of the sputter yield and the beam current.

If you double the beam current while keeping all other parameters constant, you will double the deposition rate. This makes beam current the primary lever for controlling process throughput.

Understanding the Trade-offs

Optimizing for one parameter often involves compromising on another. A successful process requires balancing these competing factors.

Energy vs. Implantation

While higher energy can increase yield, it also increases the chance of ion implantation. These embedded ions can become impurities in your target and can even be re-sputtered, leading to contamination in your deposited film.

Rate vs. Uniformity

Using an off-normal angle to maximize sputter yield can sometimes lead to a highly directional "plume" of sputtered material. As noted, this can make it difficult to achieve a uniform film thickness over a large substrate area, which is a known challenge for ion beam systems.

Rate vs. Target Damage

Pushing beam current and energy to their maximums for a high deposition rate generates significant heat on the target. This can cause the target to crack, warp, or even melt, leading to process instability and defects.

Making the Right Choice for Your Goal

Your optimal parameters depend entirely on your primary objective. Use these guidelines to inform your process development.

- If your primary focus is maximum deposition rate: Use a heavy ion (like Argon), increase ion energy into the optimal range (e.g., 500-1500 eV), find the peak yield angle (often 60-70°), and maximize the ion beam current.

- If your primary focus is depositing a film with minimal contamination: Use lower ion energy to reduce implantation and consider a high-purity noble gas like Krypton or Xenon.

- If your primary focus is sputtering a delicate or multi-component material: Use lower ion energy and current to minimize surface damage and prevent preferential sputtering of one element over another.

Mastering your sputtering process comes from understanding how these fundamental parameters interact to produce your desired outcome.

Summary Table:

| Parameter | Effect on Sputter Yield | Key Insight |

|---|---|---|

| Ion Energy | Increases to a plateau, then may decrease | Optimal range typically 500-1500 eV for maximum yield |

| Ion Mass | Higher yield with better mass match to target | Argon is common; heavier ions like Krypton for better momentum transfer |

| Angle of Incidence | Peaks at 60-80° from normal | Glancing angles deposit energy closer to surface |

| Target Material | Higher yield with lower surface binding energy | Gold/silver sputter easily; tungsten/carbon are difficult |

| Beam Current | Directly controls deposition rate (atoms/second) | Doubling current doubles rate, independent of yield |

Optimize your sputtering process with KINTEK's expertise! Whether you need to maximize deposition rates, minimize contamination, or handle delicate materials, our specialized lab equipment and consumables are designed to meet your precise laboratory requirements. Contact our experts today to discuss how we can help you achieve superior thin film results with the right ion beam parameters and equipment configuration.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis