Introduction to Molecular Mixology

Rapid Growth and Popularity

Molecular mixology has experienced a meteoric rise in popularity, capturing the imagination of bar culture enthusiasts worldwide. This innovative approach to cocktail creation has transcended traditional boundaries, blending culinary arts with scientific precision to produce unique and sophisticated drinks. The allure of molecular mixology lies in its ability to transform familiar ingredients into unexpected textures and flavors, offering a sensory experience that is both intriguing and delightful.

The rapid growth of molecular mixology can be attributed to several factors. Firstly, the increasing interest in experimental and avant-garde cuisine has paved the way for this new form of mixology. As diners and drinkers seek more adventurous and unique experiences, molecular mixology provides a platform for creativity and innovation. Secondly, the accessibility of specialized equipment, such as rotary evaporators, has made it easier for bartenders to experiment with molecular techniques, democratizing the process and broadening its appeal.

Moreover, the rise of social media and online platforms has played a significant role in the popularity of molecular mixology. Visual and interactive content showcasing the intricate processes and stunning results of molecular cocktails has garnered significant attention, inspiring a new generation of mixologists and drink aficionados. This digital exposure has not only increased awareness but also fostered a community of enthusiasts who share tips, techniques, and recipes, further fueling the growth of this exciting field.

In essence, molecular mixology's rapid growth and widespread popularity are a testament to its innovative potential and the ever-evolving nature of bar culture. As more individuals and establishments embrace this technique, the boundaries of what is possible in cocktail creation continue to expand, promising even more exciting developments in the future.

Basic Methodology

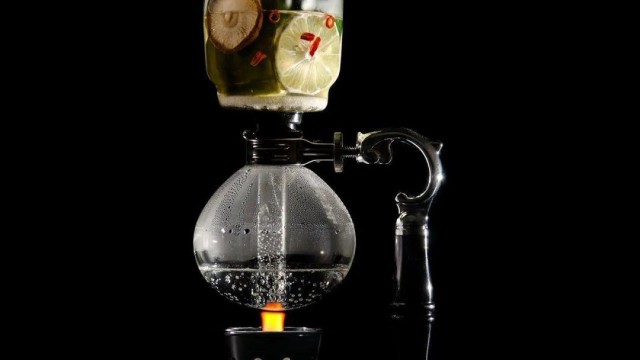

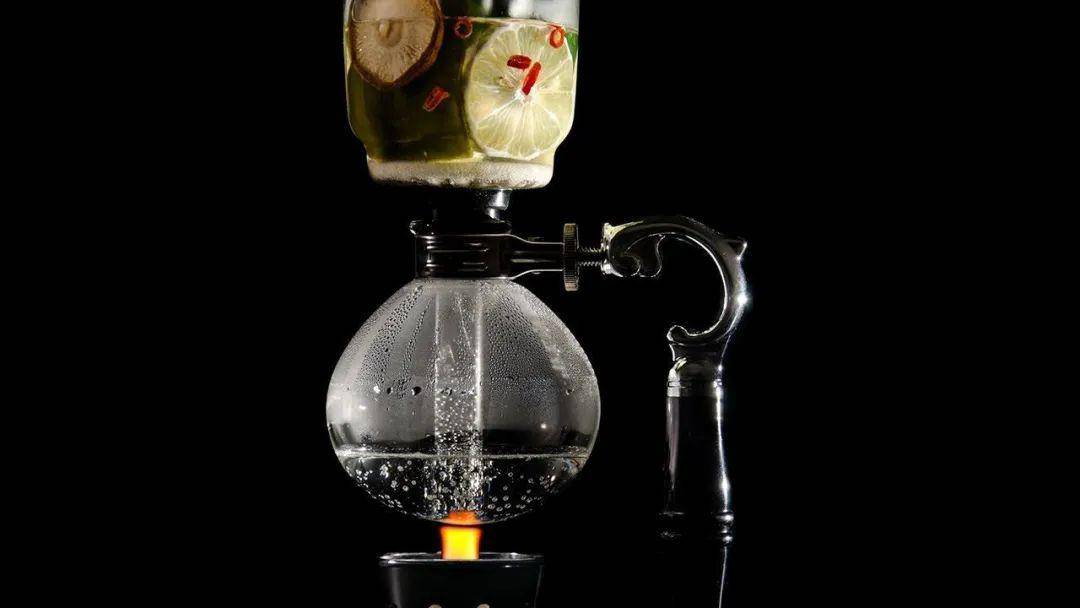

The core technique in molecular mixology involves employing rotary evaporators to meticulously distill ethanol at room temperature. This process is pivotal for extracting natural ingredients that significantly influence the aroma, taste, and color of cocktails. By maintaining ambient temperature, the rotary evaporator ensures that volatile compounds, which contribute to the distinctive flavors and scents, are not lost to excessive heat.

This methodical approach allows for the precise extraction of essential components from various natural sources, such as fruits, herbs, and botanicals. The distilled ethanol, enriched with these natural elements, becomes a concentrated essence that can be seamlessly integrated into cocktail recipes. This not only enhances the sensory experience but also allows mixologists to craft unique and complex flavors that would be challenging to achieve through traditional methods.

Moreover, the use of rotary evaporators in this context underscores the intersection of science and culinary art, enabling a more controlled and predictable outcome. This scientific rigor ensures that each batch of extracted ingredients is consistent, thereby maintaining the quality and integrity of the final cocktail product.

Scientific Basis of Molecular Cocktails

Components of Fruit Aroma

Fruit aromas are intricate mixtures of various organic compounds, each contributing to the unique scent profile of the fruit. The primary components include low-molecular-weight alcohols, esters, aldehydes, and a variety of other organic substances. These compounds are often volatile, allowing them to be readily extracted using solvents like ethanol.

| Component Type | Examples | Role in Aroma |

|---|---|---|

| Alcohols | Methanol, Ethanol | Provide a base note, enhancing overall aroma complexity |

| Esters | Ethyl acetate, Butyl acetate | Contribute to fruity and floral notes |

| Aldehydes | Hexanal, Octanal | Add freshness and green notes |

| Others | Terpenes, Ketones | Introduce additional layers of complexity and depth |

The extraction process leverages the solubility of these organic components in ethanol, which is then distilled using a rotary evaporator to isolate the aromatic compounds. This method ensures that the delicate flavors and aromas are preserved, making it an essential technique in molecular mixology for crafting sophisticated cocktails.

Example with Blueberries

Blueberries, a popular fruit in molecular mixology, contribute a complex array of aroma components that enhance the sensory experience of cocktails. Key among these are linalool, which imparts a floral and slightly citrusy note, and α-pinitol, adding a unique sweetness reminiscent of caramel or maple. Additionally, the aldehydes (E)-2-hexenal and hexanal bring fresh, green, and slightly spicy aromas, while methoxyphenyl oxime introduces a subtle, earthy undertone.

These compounds, when extracted using ethanol and distilled with a rotary evaporator, can be precisely controlled to achieve the desired balance of flavors and aromas. The process not only preserves the natural essences of the blueberries but also allows for creative adjustments to tailor the cocktail to specific tastes. This meticulous extraction method ensures that each component of the blueberry's aroma is captured and utilized effectively in the final cocktail preparation.

Preparation Process

Detailed Steps

To create a cocktail component using blueberries and brandy, follow these detailed steps:

-

Juice the Blueberries: Start by extracting the juice from fresh blueberries. This step is crucial as it captures the natural flavors and aromas of the fruit.

-

Mix with Brandy: Combine the blueberry juice with brandy. The brandy serves as a carrier for the blueberry components and adds its own distinct flavor to the mixture.

-

Distill Using a Rotary Evaporator: Transfer the mixture to a rotary evaporator. This device allows for the distillation of ethanol at room temperature, preserving the delicate organic components of the blueberry aroma.

-

Collect Ethanol: After distillation, collect the ethanol. This ethanol will be enriched with the aromatic compounds from the blueberries, making it a key ingredient in the cocktail.

-

Evaporate Residual Water: Use the rotary evaporator to evaporate any residual water from the collected ethanol. This step ensures that the final product is concentrated and potent.

-

Mix Residual Liquid with Prepared Ethanol: Finally, mix the residual liquid with the prepared ethanol. This combination forms a cocktail component that is rich in blueberry aroma and brandy flavor, ready to be incorporated into your next innovative cocktail creation.

By following these steps, you can harness the power of molecular mixology to create a unique and flavorful cocktail component.

Impact of Adjustments

Even the slightest alterations in the cocktail preparation process can significantly influence the final product. These adjustments can manifest in various ways, notably affecting the aroma, flavor, and color of the cocktail component. For instance, the temperature at which the rotary evaporator operates, the duration of the distillation process, or even the choice of ethanol used can all lead to nuanced differences in the cocktail's sensory profile.

| Adjustment Type | Potential Impact |

|---|---|

| Temperature Control | Can enhance or diminish certain aromatic compounds, altering the overall scent. |

| Distillation Duration | May concentrate specific flavors, leading to a more pronounced taste. |

| Ethanol Selection | Influences the extraction efficiency of different aroma components, affecting the cocktail's color and flavor. |

These micro-adjustments are crucial in molecular mixology, where precision and scientific rigor are paramount. Each change is not merely an aesthetic tweak but a deliberate manipulation aimed at achieving a specific sensory outcome, be it a more vibrant hue, a richer aroma, or a bolder flavor.